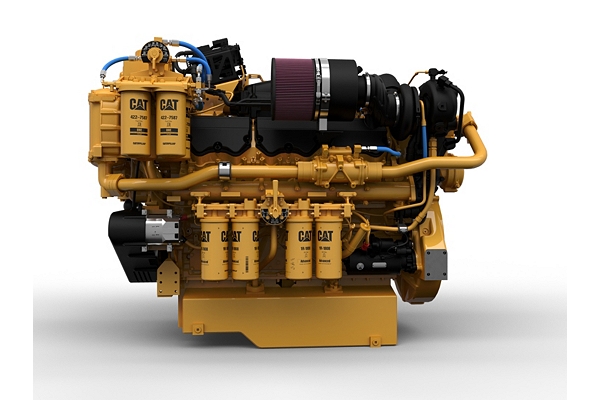

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (IMO III)

Auxiliary Engines

Auxiliary Engines (16)

-

Cat 3516B Marine Auxiliary/Generator Set Engine

-

Cat C9 Marine Generator Set Engine

-

Cat 3512B Marine Auxiliary/Generator Set Engine

-

3512E Marine Auxiliary/DEP Engine (U.S. EPA Tier 4 Final)

-

3516E Marine Auxiliary Engine (U.S. EPA Tier 4 Final)

-

Cat C280 Marine Auxiliary Engines

-

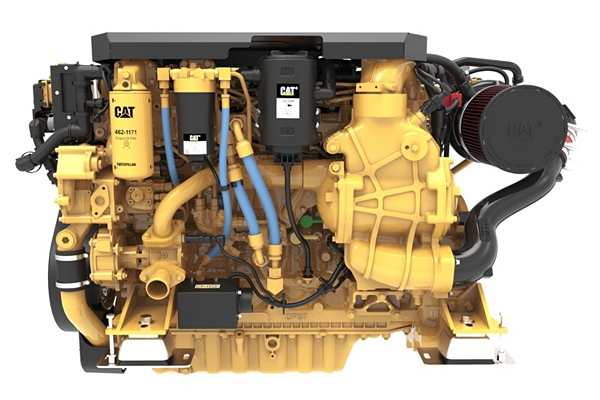

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (US EPA Tier 4 / IMO III)

-

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (IMO III)

-

Cat C32 Auxiliary / Diesel Electric Propulsion (US EPA Tier 3 / IMO II)

-

Cat C18 Auxiliary/Generator Set Engine (EPA Tier 3)

-

Cat C32 Auxiliary/Generator Set Engine (IMO II)

-

Cat C32 Auxiliary/Generator Set Engine (EPA Tier 3)

-

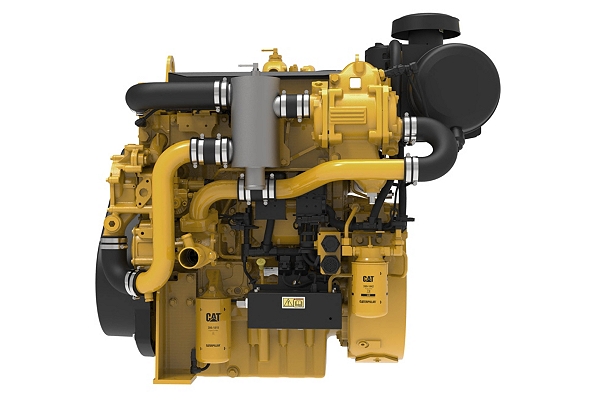

C4.4 (Electronic Control System)

-

C7.1 Marine Auxiliary Engine (U.S. EPA Tier 3 / IMO II)

-

C9.3 Marine Auxiliary Engine

-

Cat C18 Auxiliary/Generator Set Engine (IMO II)

Overview

Emissions

Utilizes SCR Technology to enable IMO III emission regulations compliance while lowering operational costs

Control Strategy

Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs; Extends emissions useful life; Ensures compliance; Flexible to urea quality

Fuel System

Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

Power Reserve

Industry leading power reserve

Certifications

Wide range of available Marine Society certifications

Warranty

Industry-leading warranty coverage for factory packaged components

Service

Global dealer network for service in any location

Emissions

Utilizes SCR Technology to enable IMO III emission regulations compliance while lowering operational costs

Control Strategy

Utilizes closed loop air assisted DEF dosing control strategy that delivers: Highest efficiency mixing and control to lower operational costs; Extends emissions useful life; Ensures compliance; Flexible to urea quality

Fuel System

Enhanced control of fuel injection optimized through crank timing and the A5 ECM technology

Power Reserve

Industry leading power reserve

Certifications

Wide range of available Marine Society certifications

Warranty

Industry-leading warranty coverage for factory packaged components

Service

Global dealer network for service in any location

Power Rating

- Minimum Rating

- 352bhp

- Maximum Rating

- 1332BHP

- Minimum Rating

- 1047BHP

Engine Specifications

- Aspiration

- Turbocharged-aftercooled aspiration

- Configuration

- Vee 12, 4-stroke-cycle diesel

- Bore

- 5.71in

- Stroke

- 6.38in

- Displacement

- 1959cu in

- Rotation

- Counterclockwise from flywheel end

- Emissions

- IMO III emissions certified (SCR required)

- Rated Engine Speed

- 1500 rpm

- Governor

- Electronic (A5 ECM)

- Refill Capacity

- Lube Oil System w/ oil filter change: 146 L (38.5 gal) - deep pan

- Oil Change Interval

- 750 hrs - deep pan

- Cooling

- Heat exchanger or keel cooled

- Flywheel Housing

- SAE No. 0 with SAE No. 18 flywheel (136 teeth)

- Aspiration

- Turbocharged-aftercooled

- Bore

- 5.71in

- Configuration

- Vee 12, 4-stroke-cycle diesel

- Displacement

- 1959in³

- Rotation

- Counterclockwise from flywheel end

- Stroke

- 6.38in

- Emissions

- IMO III emissions certified (SCR required)

- Cooling

- Heat exchanger or keel cooled

- Flywheel Housing

- SAE No. 0 with SAE No. 18 flywheel (136 teeth)

- Governor

- Electronic (A5 ECM)

- Oil Change Interval

- 750 hrs - deep pan

- Rated Engine Speed

- 1500 rpm

- Refill Capacity

- Lube Oil System w/ oil filter change: 146 L (38.5 gal) - deep pan

Dimensions & Weights

- Minimum Length

- 83.9in

- Maximum Length

- 89.8in

- Minimum Height

- 59.3in

- Maximum Height

- 63.5in

- Minimum Width

- 57.1in

- Maximum Width

- 57.3in

- Minimum Engine Dry Weight

- 6950lb

- Maximum Engine Dry Weight

- 7160lb

- Maximum Engine Dry Weight

- 7160lb

- Maximum Height

- 63.5in

- Maximum Length

- 89.8in

- Maximum Width

- 57.3in

- Minimum Engine Dry Weight

- 6950lb

- Minimum Height

- 59.3in

- Minimum Length

- 83.9in

- Minimum Width

- 57.1in

Clean Emissions Module (CEM) – Dimensions

- 6 Brick Z-Flow - Length

- 147.7in

- 6 Brick Z-Flow - Height

- 23.5in

- 6 Brick Z-Flow - Width

- 43.5in

- 6 Brick Z-Flow - Weight

- 1246lb

- 6 Brick U-Flow - Length

- 85.0in

- 6 Brick U-Flow - Height

- 23.5in

- 6 Brick U-Flow - Width

- 56.9in

- 6 Brick U-Flow - Weight

- 1235lb

- Dosing Cabinet - Length

- 37.4in

- Dosing Cabinet - Height

- 22.8in

- Dosing Cabinet - Width

- 18.8in

- Dosing Cabinet - Weight

- 209lb

Clean Emissions Module (CEM) - Dimensions

- 6 Brick U-Flow - Height

- 23.5in

- 6 Brick U-Flow - Length

- 85in

- 6 Brick U-Flow - Weight

- 1235lb

- 6 Brick U-Flow - Width

- 56.9in

- 6 Brick Z-Flow - Height

- 23.5in

- 6 Brick Z-Flow - Length

- 147.7in

- 6 Brick Z-Flow - Weight

- 1246lb

- 6 Brick Z-Flow - Width

- 43.5in

- Dosing Cabinet - Height

- 22.8in

- Dosing Cabinet - Length

- 37.4in

- Dosing Cabinet - Weight

- 209lb

- Dosing Cabinet - Width

- 18.8in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Separate circuit aftercooled (SCAC)

- Closed crankcase fumes disposal

-

- Control System

-

- 24V control system

-

- Cooling System

-

- Heat exchanger or Keel Cooling

- Watercooled exhaust manifold and turbocharger

- Hard seawater lines – no flexible hoses

- Flanges for cooling connections, ANSI or DIN

-

- Fuel System

-

- Duplex fuel filters with hybrid fuel lines

- Shipped loose primary fuel filter with water separator

- Fuel transfer and priming pump

-

- Lube System

-

- Oil fill, simplex filter and dipstick

- Deep or shallow sump oil pan

-

- Mounting System

-

- Adjustable front support mounting system

-

- General

-

- Right or left hand service sides

- Customer wiring and service tool connector

Optional Equipment:

-

- Alarm And Protection

-

- MECP I control panel

- MECP III control panel with Cat® Alarm and Protection System

-

- Exhaust System

-

- Water-in-fuel and exhaust temperature sensors

- Muffler

-

- Charging System

-

- Charging alternator

-

- Fuel System

-

- Manual or electric fuel priming pump

- Fuel cooler

-

- Lube System

-

- Duplex oil filters

-

- Power Take-offs

-

- Front drives including stub shaft and pump drive

- Rear SAE A or B pump drives

-

- Starting System

-

- Starting motors – air, electric or redundant