Cat® C9.3B Diesel Engine

Industrial

Industrial (87)

-

Cat® G3516, G3516B Industrial Gas Engines

-

Cat® G3412 Industrial Gas Engine

-

Cat® G3406 Industrial Gas Engine

-

Cat® 3412C Fire Pump

-

Cat® C9 Industrial Power Unit

-

Cat® C9 Industrial Power Unit

-

Cat® C1.5 Industrial Power Unit

-

Cat® C2.2 Industrial Power Unit

-

Cat® C13 Industrial Power Unit

-

Cat® C9.3 Industrial Power Unit

-

Cat® C1.1 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

Cat® C2.2 Industrial Power Unit

-

Cat® C9 Industrial Diesel Engine

-

Cat® C13 Diesel Engine

-

Cat® C9.3 Diesel Engine

-

Cat® C4.4 Diesel Engine

-

Cat® C2.2 Diesel Engine

-

Cat® C1.7 Diesel Engine

-

Cat® 3512 Fire Pump

-

Cat® 3406C Fire Pump Engine

-

Cat® 3508 Fire Pump

-

Cat® 3516 Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat® C18 Industrial Power Unit

-

Cat® C18 Diesel Fire Pump

-

Cat® C15 Industrial Power Unit

-

Cat® C13 Industrial Power Unit

-

Cat® C11 Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat® C4.4 Industrial Power Unit

-

Cat® C9.3B Industrial Power Unit

-

Cat® C32 Industrial Power Unit

-

Cat® C4.4 Industrial Power Unit

-

Cat® C18 Industrial Power Unit (<560 kW)

-

Cat® C15 Industrial Power Unit

-

Cat® C9.3B Industrial Power Unit HRC

-

Cat® C7.1 Industrial Power Unit

-

Cat® C4.4 Industrial Power Unit

-

Cat® 3616 Industrial Diesel Engine

-

Cat® 3612 Industrial Diesel Engine

-

Cat® 3608 Industrial Diesel Engine

-

Cat® 3606 Industrial Diesel Engine

-

Cat® 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat® 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat® 3512B Industrial Diesel Engine

-

Cat® 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat® 3508 Diesel Engine

-

Cat® C32

-

Cat® C27 Industrial Diesel Engine

-

Cat® C18 Industrial Diesel Engine

-

Cat® C15 Industrial Diesel Engine

-

Cat® 3406C Diesel Engine

-

Cat® C13 Industrial Diesel Engine

-

Cat® C11 Industrial Diesel Engine

-

Cat® C7.1 Diesel Engine

-

Cat® C7.1 Diesel Engine

-

Cat® C7 Industrial Diesel Engine

-

Cat® C4.4 Diesel Engine

-

Cat® C4.4 Diesel Engine

-

Cat®3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat® C3.6 Industrial Diesel Engine

-

Cat® C2.8 Industrial Diesel Engine

-

Cat® C2.2 Diesel Engine

-

Cat® C1.5 Diesel Engine

-

Cat® C1.1 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat® C0.5 Diesel Engine

-

Cat® 3516E Diesel Engine

-

Cat® C32 Diesel Engine

-

Cat® C27 Diesel Engine

-

Cat® C9.3B Diesel Engine

-

Cat® C4.4 Diesel Engine

-

Cat® C7.1 ACERT™ Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C3.6 Diesel Engine

-

Cat® C2.8 Diesel Engine

-

Cat® C2.2 Diesel Engine

-

Cat® C1.5 Diesel Engine

-

Cat® C0.5 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat® C1.1 Diesel Engine

Overview

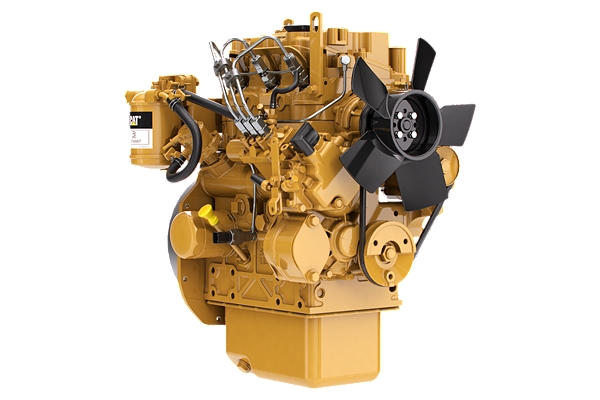

The Cat® C9.3B industrial diesel engine is offered in ratings ranging from 250-340 kW (335-456 hp) @ 1800-2200 rpm. These ratings meet U.S. EPA Tier 4 Final, EU Stage V, China Nonroad (NR) Stage IV, Japan 2014, and Korea Stage V emission standards.

- Installation

- Advanced Features

- Ideal Applications

- Total Cost of Ownership

- Cat Dealer Product Support

- Safety

Installation

With a full list of configurable options and an engine-mounted aftertreatment, the Cat C9.3B is an easy-to-install option that offers the power of larger engine platforms in a smaller engine package.

Advanced Features

Inlet throttle valve technology manages heat and in-cylinder dosing to create seamless DPF regeneration and a high-pressure common rail fuel system elimates the need for coolers, creating a simpler and lighter engine that's 18% more powerful than its predecessor engine—so operators get work done n...

Ideal Applications

Industrial, agricultural and construction applications such as: Pumps • Compressors • Chippers • Grinders • Asphalt paving equipment • Hydraulic power units • Bore rigs • Drill rigs • Tractors

Total Cost of Ownership

Between 500-hour oil service and 5000-hour DPF ash intervals and Caterpillar-patented design technology that enables the removal of EGRs, the need for parts and service keeps lifetime engine ownership costs down and ROI up. And because the Cat C9.3B uses the latest injector technology, owners can be...

Cat Dealer Product Support

Expert assistance is never far away with the Cat C9.3B. With an included warranty and product support through the expansive global Cat dealer network, worldwide service and maintenance is all part of the package. See your Cat dealer for details.

Safety

The Cat C9.3B is a finely tuned machine, running quieter and more efficiently than previous engines making it safer for job site operators who can stay focused on the task at hand.

Installation

With a full list of configurable options and an engine-mounted aftertreatment, the Cat C9.3B is an easy-to-install option that offers the power of larger engine platforms in a smaller engine package.

Advanced Features

Inlet throttle valve technology manages heat and in-cylinder dosing to create seamless DPF regeneration and a high-pressure common rail fuel system elimates the need for coolers, creating a simpler and lighter engine that's 18% more powerful than its predecessor engine—so operators get work done no matter when, no matter what.

Ideal Applications

Industrial, agricultural and construction applications such as: Pumps • Compressors • Chippers • Grinders • Asphalt paving equipment • Hydraulic power units • Bore rigs • Drill rigs • Tractors

Total Cost of Ownership

Between 500-hour oil service and 5000-hour DPF ash intervals and Caterpillar-patented design technology that enables the removal of EGRs, the need for parts and service keeps lifetime engine ownership costs down and ROI up. And because the Cat C9.3B uses the latest injector technology, owners can benefit from an overall fuel consumption reduction of up to 8% when compared to its predecessor engine.

Cat Dealer Product Support

Expert assistance is never far away with the Cat C9.3B. With an included warranty and product support through the expansive global Cat dealer network, worldwide service and maintenance is all part of the package. See your Cat dealer for details.

Safety

The Cat C9.3B is a finely tuned machine, running quieter and more efficiently than previous engines making it safer for job site operators who can stay focused on the task at hand.

General

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Cooling System Capacity

- 22 L (23.6 qts)

- Lube System (refill)

- 30 L (31.7 qts)

- Bore

- 4.5in

- Stroke

- 5.9in

- Displacement

- 567.5in³

- Aspiration

- Turbocharged-Aftercooled (TA)

- Compression Ratio

- 17.0:1

- Combustion System

- Direct Injection

- Rotation from Flywheel End

- Counterclockwise

- Engine Configuration

- In-Line 6

- Bore

- 115 mm (4.53 in)

- Stroke

- 149 mm (5.87 in)

- Displacement

- 9.3 L (567.5 in³)

- Cooling System - Capacity

- 22 L (23.6 qts)

- Lube System - Refill

- 30 L (31.7 qts)

- Aftertreatment

- DOC+DPF+SCR

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 1125 mm (44.3 in)

- Width

- 791 mm (31.1 in)

- Height

- 1068 mm (42 in)

- Weight - Net Dry (Basic Operating Engine Without Optional Attachments)

- 865 kg (1907 lb)

Aftertreatment Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 925 mm (36.4 in)

- Width

- 694 mm (27.3 in)

- Height

- 432 mm (17.0 in)

- Weight

- 96 kg (211 lb)

Power Rating

- Minimum Power

- 335HP

- Maximum Power

- 456HP

- Rated Speed

- 1800-2200 rpm

- Maximum Torque

- 1540lb-ft @ 1400 rpm

Emission Standards

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

Engine Dimensions - Approximate

- Height

- 1068 mm (42 in)

- Length

- 1125 mm (44.3 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 865 kg (1907 lb)

- Width

- 791 mm (31.1 in)

- Width

- 31in

- Height

- 42in

- Length

- 44in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 1907lb

Aftertreatment Dimensions - Approximate

- Height

- 432 mm (17.0 in)

- Length

- 925 mm (36.4 in)

- Weight

- 96 kg (211 lb)

- Width

- 694 mm (27.3 in)

Aftertreatment Dimensions

- Length

- 36in

- Width

- 27in

- Height

- 17in

- Weight

- 211lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Turbocharged

- Air-to-Air Aftercooled

- Mid-mount turbocharged system with front and rear exhaust configurations

-

- Control System

-

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Integrated Electronic Control Unit (ECU)

- Remote fan control

-

- Cooling System

-

- Vertical or RH thermostat outlet

- Centrifugal water pump

- Guidance on cooling system design available through your dealer to ensure equipment reliability

-

- Flywheels And Flywheel Housing

-

- Available SAE 1 power take-off with optional SAE B, SAE C power take-off drives. Engine power can also be taken from the front of the engine with optional attachments. (Tier 4 Final, Proposed Stage V)

-

- Fuel System

-

- Electronic high pressure common rail

- Primary fuel filter

- Secondary and tertiary fuel filters

- Fuel transfer pump

- Electronic fuel priming

-

- Lube System

-

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Oil dipstick

- Gear driven oil pump

- Choice of front, rear or center sumps

- Open crankcase ventilation system with fumes disposal (optional OCV filter system)

-

- Power Take Off (pto)

-

- SAE B or SAE C power take off (PTO) drives. Engine power can also be taken from the front of the engine on some applications.

-

- General

-

- Paint: Caterpillar yellow, with optional colors available at request

- Vibration damper

- Lifting eyes

-

- Aftertreatment System

-

- Clean Emissions Module (CEM) consisting of Diesel Particulate Filter (DPF), Diesel Oxidation Catalyst (DOC) and high-efficiency Selective Catalytic Reduction (SCR)

- Pump Electronic Control Unit (PETU)

- Available in 12V or 24V systems

Optional Equipment: