CM32E

Diesel Generator Sets

Diesel Generator Sets (181)

-

CM43C (Inline)

-

CM46DF (V-Type)

-

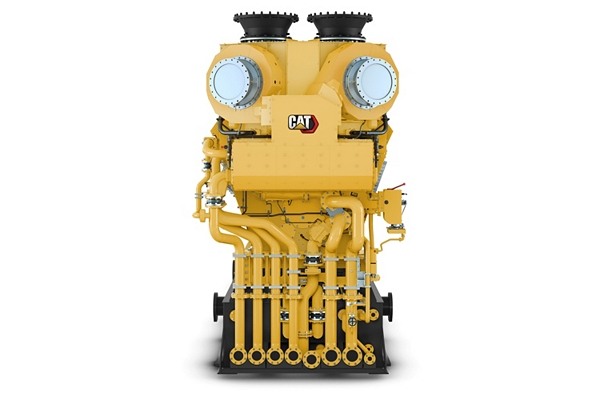

CM32E

-

CM25E Generator Set

-

CM32C (V-Type) Generator Set

-

CM32C (Inline) Generator Set

-

3516C Generator Set

-

DE800 GC

-

C15 Tier 4 Interim

-

C27 Tier 4 Interim

-

3516E High Voltage Generator Set

-

C32 Generator Set with Upgradeable Packaging

-

3516B (50 Hz) with Upgradeable Package

-

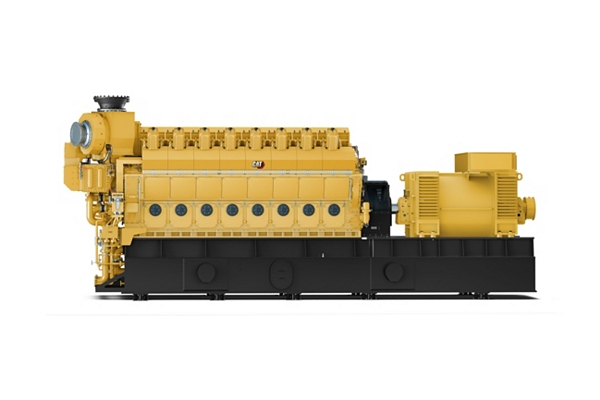

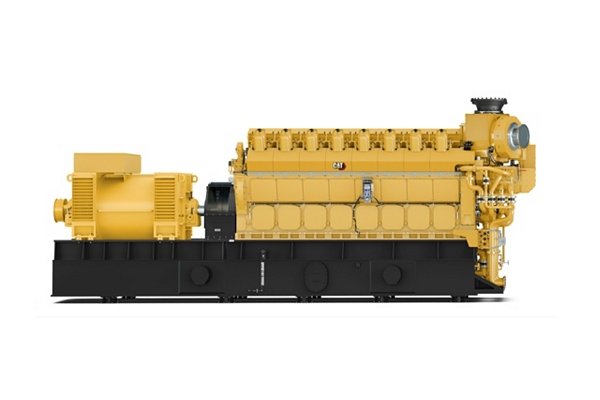

C280-16 Generator Set (Medium Speed)

-

C280-12 Generator Set (Medium Speed)

-

3616 Generator Set (Medium Speed)

-

3616 Generator Set (Medium Speed)

-

C280-8 Generator Set (Medium Speed)

-

3612 Generator Set (Medium Speed)

-

3612 Generator Set (Medium Speed)

-

3608 Generator Set (Medium Speed)

-

3608 Generator Set (Medium Speed)

-

C280-6 Generator Set (Medium Speed)

-

3606 Generator Set (Medium Speed)

-

C175-20

-

3606 Generator Set (Medium Speed)

-

C175-20

-

C175-16 Tier 4 Final

-

C175-16 Generator Set

-

C175-16 Generator Set

-

3516E Low Voltage Generator Set

-

3516E Generator Set

-

3516E Low Voltage Generator Set

-

3516E Generator Set

-

3516E Low Voltage Generator Set

-

3516C Tier 4 Final

-

3516C Generator Set

-

3516C (50 Hz) with Upgradeable Package

-

3516C Generator Set

-

3516B (60 Hz) with Upgradeable Package

-

3516B Generator Set

-

3516B Generator Set

-

3516B (50 Hz) Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516 Diesel Generator Set

-

3516B (50 Hz) India Market Only

-

3516 Diesel Generator Set

-

3512C Generator Set

-

3516 Diesel Generator Set

-

3516 Diesel Generator Set

-

3512B Diesel Generator Set

-

3512B Diesel Generator Set

-

3512C Generator Set

-

3512B Diesel Generator Set

-

3512B Diesel Generator Set

-

3512B (50 Hz) Generator Set

-

3512B (50 Hz) India Market Only

-

3512B (50 Hz) Generator Set

-

3512 with Upgradeable Package

-

3512 Generator Set

-

3512 Generator Set

-

3512 Generator Set

-

DE1500 GC

-

DE1250S GC

-

C32 (60 Hz)

-

D1250 GC

-

DE1250 GC (50 Hz)

-

DE1400 GC

-

C32 Generator Set

-

D1000 GC

-

DE1100 GC

-

C32 (50 Hz) India Market Only

-

DE1000S GC

-

C27 Generator Set

-

DE800S GC

-

C18 Generator Set

-

3412C Generator Set

-

3412C Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

D600 GC (60 Hz) Generator Set

-

DE600S GC Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

DE715 GC Generator Set

-

D550 GC (60 Hz) Generator Set

-

C18 (50 Hz) India Market Only

-

C18 Generator Set

-

DE550S GC (60 Hz) Generator Set

-

DE605 GC (50 Hz) Generator Set

-

DE660 GC (50 Hz) Generator Set

-

D500 GC (60 Hz) Generator Set

-

C15 Generator Set

-

C15 Generator Set

-

DE500S GC (60 Hz) Generator Set

-

DE450S GC (60 Hz) Generator Set

-

D450 GC (60 Hz) Generator Set

-

C15 Generator Set

-

DE550 GC (50 Hz) Generator Set

-

C15 (50 Hz) China Non Road

-

C15 (50 Hz) India Market Only

-

C13 Generator Set

-

DE500 GC (50 Hz) Generator Set

-

D400 GC (60 Hz) Generator Set

-

C13 Generator Set

-

C13 (50 Hz) China Non Road

-

DE450 GC (50 Hz) Generator Set

-

C13 Generator Set

-

C13 (50 Hz) India Market Only

-

DE400 GC Generator Set

-

D350 GC (60 Hz) Generator Set

-

DE400S GC Generator Set

-

C9 Generator Set

-

C9 Generator Set

-

D300 GC (60 Hz) Generator Set

-

C9 Generator Set

-

DE350S GC Generator Set

-

D250 GC (60 Hz) Generator Set

-

C7.1 Generator Set

-

D200 GC Generator Set

-

DE220 GC (50 Hz) Generator Set

-

C7.1 ACERT

-

C7.1 ACERT

-

D175 GC Generator Set

-

DE218AE0 (60 Hz) Generator Set

-

DE200 GC Generator Set (60 Hz)

-

DE169AE0 (60 Hz) Generator Set

-

DE218AE0 (50 Hz) Generator Set

-

DE165 GC Generator Set (60 Hz)

-

DE200 GC Generator Set (50 Hz)

-

DE150 GC Generator Set (60 Hz)

-

DE165 GC Generator Set (50 Hz)

-

D150 GC Generator Set

-

DE169AE0 (50 Hz) Generator Set

-

DE150 GC Generator Set (50 Hz)

-

D125 GC Generator Set

-

C4.4 Generator Set

-

C4.4 Generator Set

-

C4.4 Generator Set

-

DE110 GC Generator Set (60 Hz)

-

DE125AE0 (60 Hz) Generator Set

-

DE125AE0 (50 Hz) Generator Set

-

D100 GC Generator Set

-

DE110 GC Generator Set (50 Hz)

-

DE88 GC Generator Set (60 Hz)

-

DE100AE0 (60 Hz) Generator Set

-

DE100AE0 (50 Hz) Generator Set

-

DE88 GC Generator Set (50 Hz)

-

D80 GC Generator Set

-

C4.4 Generator Set

-

DE65 GC Generator Set (60 Hz)

-

C3.3 Generator Set

-

D60 GC Generator Set

-

DE75AE0 (60 Hz) Generator Set

-

C3.3 Generator Set

-

DE65 GC Generator Set (50 Hz)

-

DE75AE0 (50 Hz) Generator Set

-

DE55 GC Generator Set (60 Hz)

-

DE56AE0 (60 Hz) Generator Set

-

D50 GC Generator Set

-

D40 GC Generator Set

-

DE50 GC Generator Set (60 Hz)

-

DE55 GC Generator Set (50 Hz)

-

DE50 GC Generator Set (50 Hz)

-

DE56AE0 (50 Hz) Generator Set

-

DE33 GC Generator Set (60 Hz)

-

DE33 GC Generator Set (50 Hz)

-

C2.2 | D25 Generator Set

-

C2.2 | D20 Generator Set

-

C2.2 | D30 Generator Set

-

C2.2 Generator Set

-

C1.5 Generator Set

-

C2.2 Generator Set

-

C1.1 Generator Set

-

C1.5 Generator Set

-

C1.1 Generator Set

Overview

Caterpillar electric power stands for reliable energy supply. Especially during the energy system transformation, Cat generator sets close the energy gap caused by renewable energy source such as wind and photo voltaic. Short ramp up time, low operating costs and rapid maintenance times ensures a high availability according to the need of our customers. Combined heat /cool and power solutions allow our customers to maximize the efficiency and earnings paired with low emissions. Wherever power is needed around the globe, Caterpillar is able to support you with the best products and services to maximize your profit.

- Reliable Operation

- Control & Monitoring

- Ease Of Installation

- Ease Of Operation

- Intelligent Simplicity

- Ease Of Maintenance

- Fuel

- Emissions

- Expertise & Experience

Reliable Operation

- Intensive cooling of key components including exhaust valve seats, injector cooling integrated into lube oil system

- Reliable, proven and high efficient single turbo charging system

- Classification society standards ensure high safety and quality

- Intelligent simplicity ensures a robust engine platform

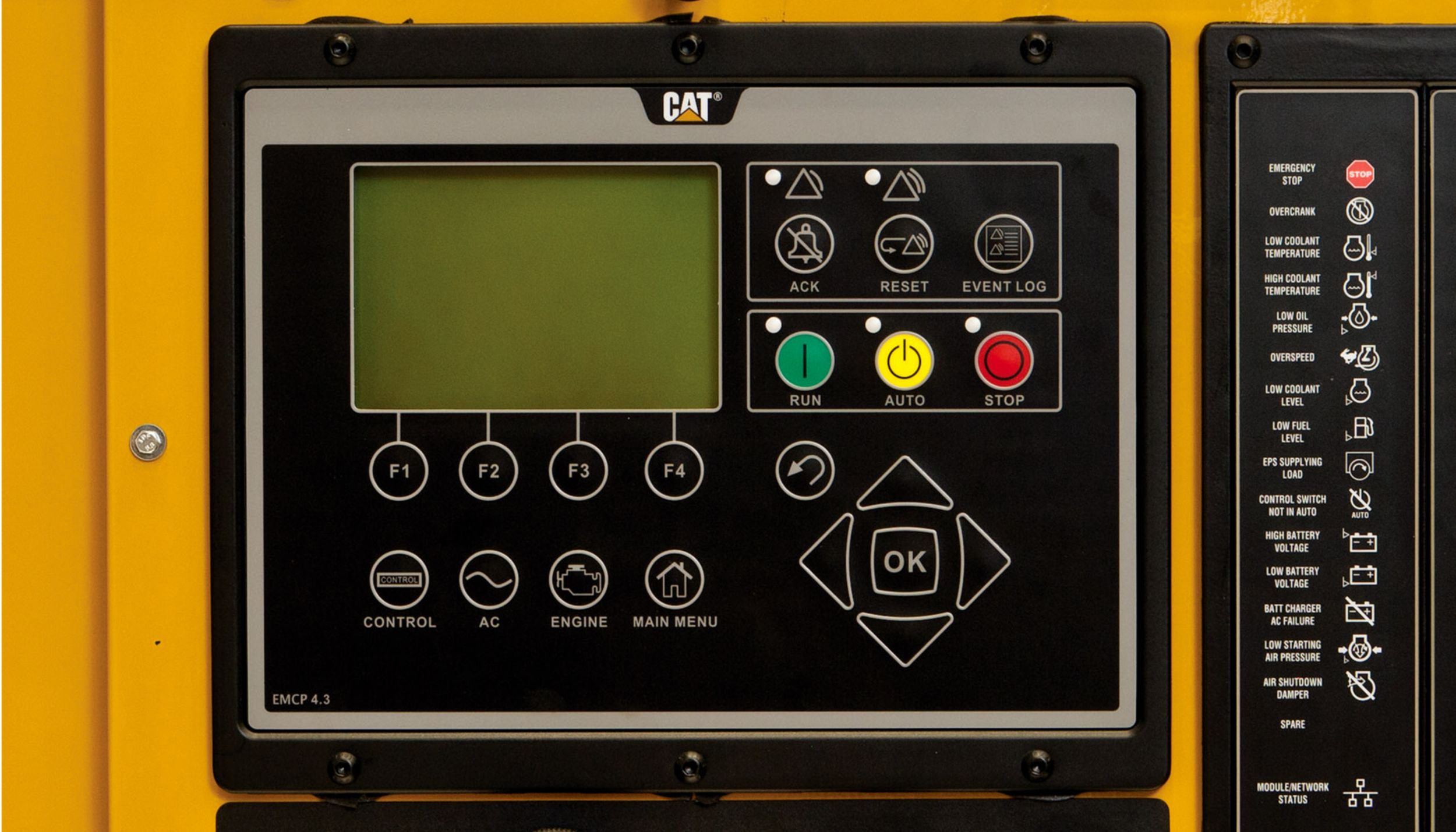

Control & Monitoring

- Ultrafast start time and load acceptance

- No engine start limitations

- Continuous power (base and peak load), prime power, stand-by

- Part load with high efficiency

- Monitoring for unattended operation

- Asset intelligence system

Ease Of Installation

- Reduced complexity of standard modular design allows an easy installation

- Low space requirements between the gensets

- Genset is ready for installation

- Generator set designed for direct elastic mounting

Ease Of Operation

- Low fuel and oil consumption

- Low maintenance requirements

- Operator and maintenance training courses available

Intelligent Simplicity

- High reliability, modular design and integral construction reduce the number of components by 40% over conventional designs e.g.:

- Dry engine block with integrated ducts for lubricating oil and charge air and underslung crankshaft

- Compact cylinder head design - Smart maintenance solutions:

- Easily removable cylinder heads, quick removable fluid connections

- Split connecting rods to allow fast and easy piston removal without disturbing the big end bearing

- Segmental camshaft design

- Simplified parts spectrum by using single-pipe exhaust gas

- Engine block free from cooling water

Ease Of Maintenance

- Smart maintenance solutions allow an easy component accessibility

- Large inspection openings afford an easy serviceability to core engine internals

- Core engine components designed for reconditioning and reuse

- Short maintenance times enable high availability

- No engine removal necessary for maintenance and overhauls

Fuel

- Liquid: Light fuel oil (LFO), crude oil and heavy fuel oil (HFO) with fuel quality up to 700 cSt/50°C according to CIMAC H55/K55

- Dual:

- Light fuel oil (LFO), crude oil and heavy fuel oil (HFO) with fuel quality up to 700 cSt/50°C according to CIMAC H55/K55

- Natural gas with methane number > 80 and lower heating value of 28MJ/Nm3

Emissions

- World bank emission certification (Stage 2)

- Technische Anleitung (TA) Luft (only gas)

- Post-emission treatment systems for lower emission requirements available

Expertise & Experience

- Assistance for planning - delivery - commissioning - operation and service)

- Expertise and experience for solutions to maximize benefits, e.g. combine heat and power systems (CHP)

Reliable Operation

- Intensive cooling of key components including exhaust valve seats, injector cooling integrated into lube oil system

- Reliable, proven and high efficient single turbo charging system

- Classification society standards ensure high safety and quality

- Intelligent simplicity ensures a robust engine platform

- Optimized service schedules enable high availability and long durability

Control & Monitoring

- Ultrafast start time and load acceptance

- No engine start limitations

- Continuous power (base and peak load), prime power, stand-by

- Part load with high efficiency

- Monitoring for unattended operation

- Asset intelligence system

Ease Of Installation

- Reduced complexity of standard modular design allows an easy installation

- Low space requirements between the gensets

- Genset is ready for installation

- Generator set designed for direct elastic mounting

Ease Of Operation

- Low fuel and oil consumption

- Low maintenance requirements

- Operator and maintenance training courses available

Intelligent Simplicity

- High reliability, modular design and integral construction reduce the number of components by 40% over conventional designs e.g.:

- Dry engine block with integrated ducts for lubricating oil and charge air and underslung crankshaft

- Compact cylinder head design - Smart maintenance solutions:

- Easily removable cylinder heads, quick removable fluid connections

- Split connecting rods to allow fast and easy piston removal without disturbing the big end bearing

- Segmental camshaft design

- Simplified parts spectrum by using single-pipe exhaust gas

- Engine block free from cooling water - State-of-art material ensures long life time

Ease Of Maintenance

- Smart maintenance solutions allow an easy component accessibility

- Large inspection openings afford an easy serviceability to core engine internals

- Core engine components designed for reconditioning and reuse

- Short maintenance times enable high availability

- No engine removal necessary for maintenance and overhauls

Fuel

- Liquid: Light fuel oil (LFO), crude oil and heavy fuel oil (HFO) with fuel quality up to 700 cSt/50°C according to CIMAC H55/K55

- Dual:

- Light fuel oil (LFO), crude oil and heavy fuel oil (HFO) with fuel quality up to 700 cSt/50°C according to CIMAC H55/K55

- Natural gas with methane number > 80 and lower heating value of 28MJ/Nm3 - Gaseous: Natural gas with methane number > 80 and lower heating value of 31.5 MJ/Nm3

Emissions

- World bank emission certification (Stage 2)

- Technische Anleitung (TA) Luft (only gas)

- Post-emission treatment systems for lower emission requirements available

Expertise & Experience

- Assistance for planning - delivery - commissioning - operation and service)

- Expertise and experience for solutions to maximize benefits, e.g. combine heat and power systems (CHP)

Generator Set Specifications

- Minimum Rating

- 3085 kWe

- Maximum Rating

- 4630 kWe

- Emissions/Fuel Strategy

- (WB) Cert stage 1 and 2

- Voltage

- 3000 to 13800 Volts

- Frequency At Speed

- 50 Hz @ 750 / 60 Hz @ 720

- Duty Cycle

- Prime, Continuous

- Ready To Accept Loads (Preheated/Vented)

- 40 s

- Normal Ramp Up To 100% Load

- 95 s

- Emergency Ramp Up 10% To 100% Load

- 30 s

- Genset Efficiency Up To

- 46.40%

Engine Specifications

- Engine Model

- CM32E, 4-stroke-engine

- Bore

- 12.6in

- Stroke

- 18.11in

- Aspiration

- Turbocharged-aftercooled

- Engine Rating Range

- 3150 - 4725 kW

- Configuration

- 6,8,9 cylinder

- Fuel Type

- Diesel oil / heavy fuel oil (HFO) / crude oil

- Swept Volume

- 2258in³

- Mean Effective Pressure Up To

- 344psi

- Specific Fuel Oil Consumption (WB I) Up To

- 0.392Ib/kWh

- Specific Fuel Oil Consumption (WB II) Up To

- 0.392Ib/kWh

- Specific Lube Oil Consumption

- 0.001Ib/kWh

Generator Set Dimensions

- Length - Minimum

- 377in

- Length - Maximum

- 439in

- Width - Minimum

- 102in

- Width - Maximum

- 102in

- Height - Minimum

- 180in

- Height - Maximum

- 188in

- Dry Weight - Genset (minimum)

- 156528lb

- Dry Weight - Genset (maximum)

- 216053lb

Standard/Optional Features

Standard Equipment:

-

- Fuel System

-

- Gas valve unit (GVU) (only dual fuel (DF) and gas)

- Ignition fuel oil module (only dual fuel (DF))

- Circulation module

- Pre-pressure module

- Engine ventilation module (only dual fuel (DF) and gas)

- Separator module

-

- Lubricating Oil System

-

- Combined module: cooling water system and lube oil system

- Lube oil separator module

- Piping interface module

-

- Cooling Water System

-

- Cooling water system with radiators

- Combined module: see lube oil system

- Piping interface module

-

- Starting System

-

- Starting air compressor module

- Starting air receiver module

-

- Combustion Air System

-

- Air filter - oil bath

- Air filter - pocket

- Air filter - pulse

-

- Exhaust System

-

- Selective catalytic reduction (SCR) system

- Exhaust gas silencer

- Exhaust gas ventilation module (only dual fuel (DF) and gas)

- Oxidation catalytic (Oxicat) converter system

-

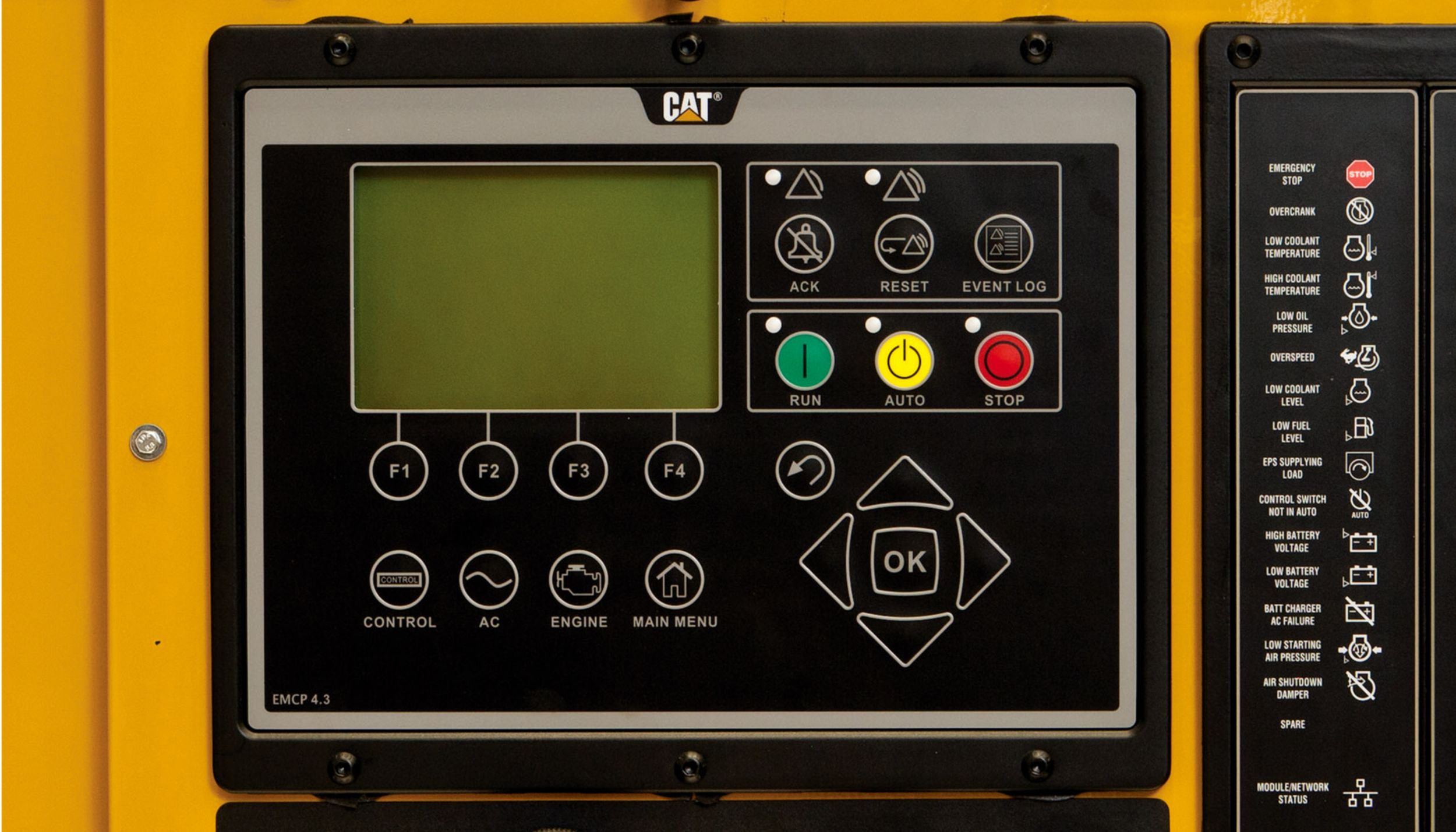

- Control & Monitoring System

-

- Motor control center module (MCC)

- Engine monitoring package

- Gas leak detection per cylinder (only dual fuel (DF) and gas)

- Local control panel (LCP)

- Local data panel (LDP) / generator control panel (GCP)

-

- Mounting System

-

- Elastic mounting - genset/engine

Optional Equipment: