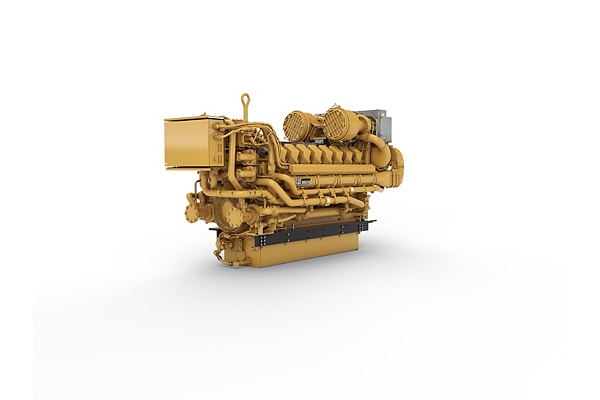

C175-16 Propulsion Engine

-

C175-16 Propulsion Engine

-

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

-

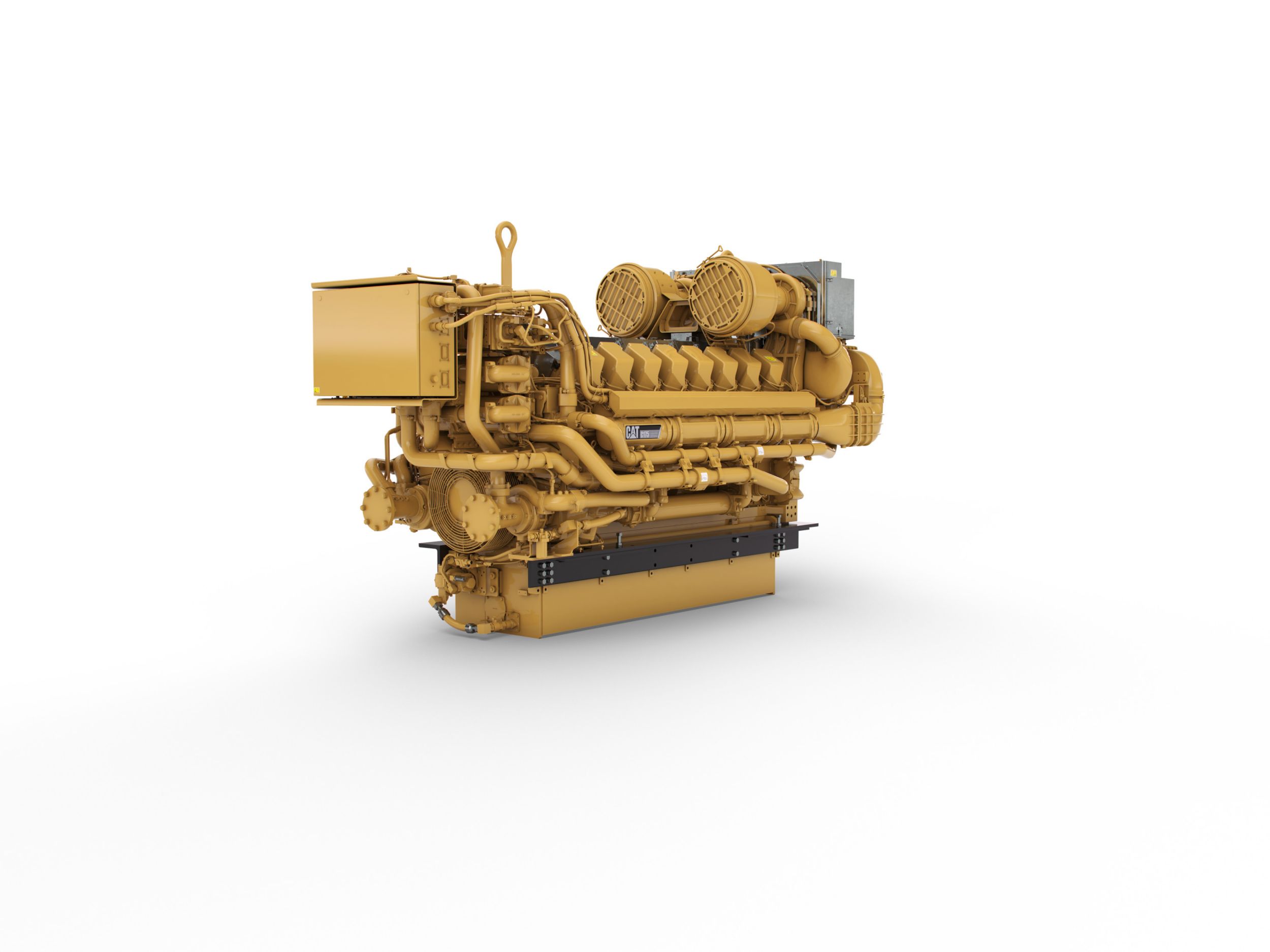

C280-8 Marine Propulsion Engine (U.S. EPA Tier 4)

-

C280-12 Propulsion Engine

-

C280-12 Marine Propulsion Engine (EPA Tier 4)

-

C280-16 Commercial Marine Propulsion Engine

-

3516E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

C280-6 Propulsion Engine

-

Cat C280-8 Propulsion Engine

-

3512E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3516C Marine Propulsion Engine

-

3516C Propulsion Engine (Tier 3)

-

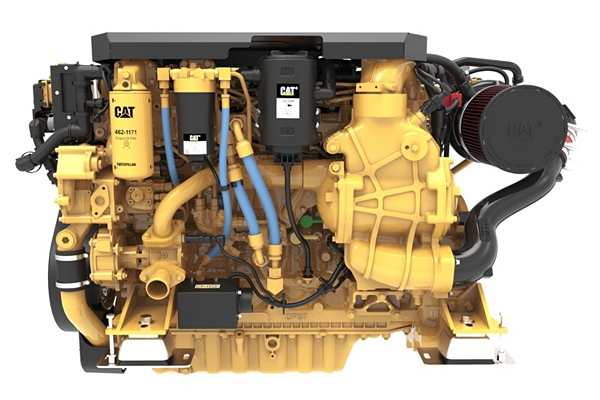

Cat C32 Propulsion Engine (US EPA Tier 4 / IMO III)

-

3508C Propulsion Engine

-

3512C Propulsion Engine (IMO II)

-

3512C Tier 3 Marine Propulsion Engine

-

3406C Propulsion Engine

-

Cat C32 ACERT Marine Propulsion Engine (EPA Tier 3)

-

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

-

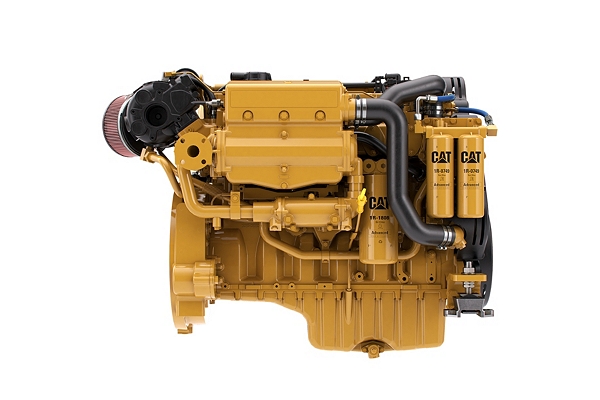

Cat C18 ACERT Propulsion Engine (IMO II)

-

Cat C18 ACERT Propulsion Engine (Tier 3)

-

Cat C32 Propulsion Engine (IMO II)

-

C7.1 Marine Propulsion Engine (U.S. EPA Tier 3 / IMO II)

-

C9.3 Commercial Propulsion Engine

-

C12 Propulsion Engine

Overview

The C175-16 is the first Cat marine engine with core ACERTTM Technology, designed and built from the ground up. This offers maximum performance along with EPA Marine Tier 3 and IMO Tier II emissions compliance with no aftertreatment. With unrestricted continuous and heavy-duty ratings, you get morepower with plenty of room for growth, so you maximize productivity while minimizing cost of ownership. With a bore of 175 mm (6.9 in) and a stroke of 220 mm (8.66 in), the C175-16 is highly efficient while providing increased propulsion output in a high speed engine platform. Additional features include: Turbocharged and aftercooled aspiration, MCS approved monitoring, alarm, and protection system. Cross-flow head design, simplified electrical system. The C175-16 is backed by a Caterpillar warranty and the best service network in the industry. The global Cat dealer network means customers can count on the service and support they need for their marine engines no matter where their vessel is located.

- Making Your Investment Work Harder

- Driving Down Total Cost of Ownership

- Committed to Sustainable Development

- Improving Workforce Efficiency

- Fully Integrated Marine Power Solution

- Caterpillar Common Rail System

- Cross-flow head design

- Simplified electrical system

- New generation of turbochargers designed specifically for the C175

- Marine Classification Society approved monitoring, alarm, and protection system

- Thermo-laminated heat shields for exhaust components

Power Rating

- Power Range

- 2683-3420 bhp (2001-2550 bkW)

- Power Range

- 2683-3420 bhp (2001-2550 bkW)

Engine Specifications

- Speed Range

- 1600-1800 rpm

- Emissions

- IMO II

- Aspiration

- TA

- Bore

- 6.88in

- Stroke

- 8.66in

- Displacement

- 5166.88in3

- Configuration

- Vee 16, 4-Stroke-Cycle Diesel

- Rotation from Flywheel End

- Counterclockwise

- Speed Range

- 1600-1800 rpm

- Emissions

- IMO II

- Aspiration

- TA

- Bore

- 6.88in

- Stroke

- 8.66in

- Displacement

- 5166.88in³

Dimensions & Weights

- Dry Weight

- 28750.0lb

- Width

- 72.6in

- Length

- 177.8in

- Height

- 97.6in

- Dry Weight

- 28750lb

- Width

- 72.6in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Air cleaner; 2 single element canisters

- Air cleaner mounting

-

- Control System

-

- Caterpillar Dual ADEM A4 Electronic Engine Control, front mtd.Requires 24V DC 20 amp continuous, 40 amp intermittent, clean electrical power

-

- Cooling System

-

- Engine Configuration for Remote Cooling

-

- Exhaust System

-

- Dry Exhaust Manifold and dual turbochargers with heat shields

-

- Flywheels & Flywheel Housings

-

- Flywheel housing, SAE No. 00

- Flywheel, 530 M (SAE No. 21), 183 teeth

-

- Fuel System

-

- Fuel transfer pump, RH Fuel priming pump, RH Double walled high pressure fuel lines Electronically controlled unit injectors Leak detection Customer connections, RH Shipped loose duplex primary fuel filters with water separators Duplex secondary and tertiary fuel filters

-

- Instrumentation

-

- Features: Start/stop controls Emergency stop Terminal blocks for customer connections

- Switches: Cranking override-RH and LH Crank selection Low idle Prelube override

- Graphical Unit (Color Marine Power Display) for analog or digital of: Engine oil pressure, engine water temperature, fuel pressure, system DC voltage, air inlet restriction, LH & RH exhaust temperature (prior to turbocharger), fuel filter differential, oil filter differential, service hour meter, engine speed, instantaneous fuel consumption (calculated), total fuel consumed (calculated), engine control switch (4 position), alarn horn, prioritized alarms, backup ECM ready light, backup ECM in control light, overspeed shutdown notification light, emergency stop notification light, prelube override, shutdown override

- Indication lights: Auxiliary one and two circuits Emergency stop lamp General alarm lamp Local speed control

-

- Lube System

-

- Gear type lube oil pump Integral lube oil cooler Oil drain valves, FRONT Oil sampling valve Duplex oil filter Filler and dipstick Fumes disposal 1000 hour sump oil pan

-

- Protection System

-

- A4 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions.

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection: Oil pressure and water temperature(redundant OP and WT sensors) Overspeed (redundant and independent of engine governing system speed sensed by backup ECM which is MCS approved) NOT INCLUDED: Thermocouples

-

- Starting System

-

- High and Low current power distribution box NOT INCLUDED: Starting motor

-

- Marine Society Requirements

-

- See MARINE SOCIETY REQUIREMENTS optional attachments

-

- General

-

- Vibration damper and guard Lifting eyes Paint, Caterpillar yellow engine with black rails. Preservation of cooling system, air intake and exhaust for one year indoor storage

Optional Equipment:

-

- Imo Certification (emissions)

-

- For GL IMO certification for vessels with a German Flag, additional certificatio nthrough the German Authority SeeBG is required.

-

- Charging System

-

- Alternator Harness: 10M/32FT, 20M/64FT, 30M/98FT

- Battery Charger 20 AMP

-

- Cooling System

-

- Coolant Level Sensor

-

- Exhaust System

-

- Flexible Fitting

- Flanges

- Flange & Exhaust Expanders

-

- Fuel System

-

- Flexible Fuel Lines

-

- Instrumentation

-

- PL 1000E Communication Module

- Marine Gear Sensors

- Color Marine Power Display System

- Turbocharger Speed Sensors

-

- Lube System

-

- Electric Prelube Harness

-

- Special Tests/reports

-

- Special Test Charge - English Only

- STD Engine Test Charge

-

- Starting System

-

- 24 Volt Battery Set - Dry (QTY6)

- Starter Motor Harness

-

- Service Tools/ship Prot./ Factory Support

-

- Shrink Wrap Protection

- Export Packaging