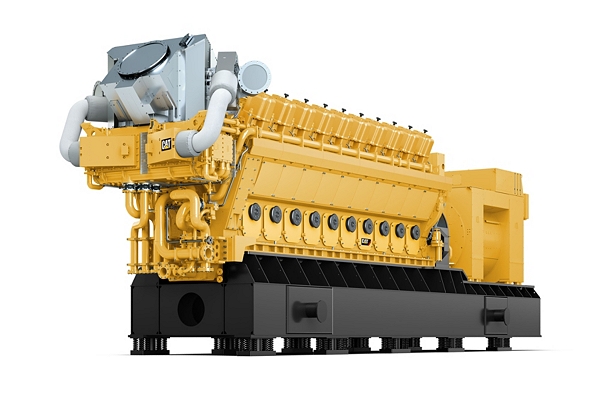

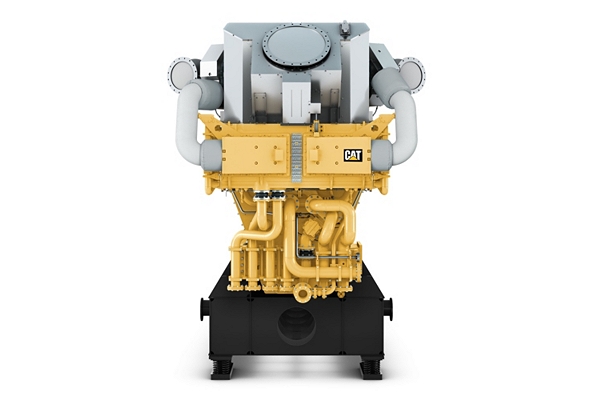

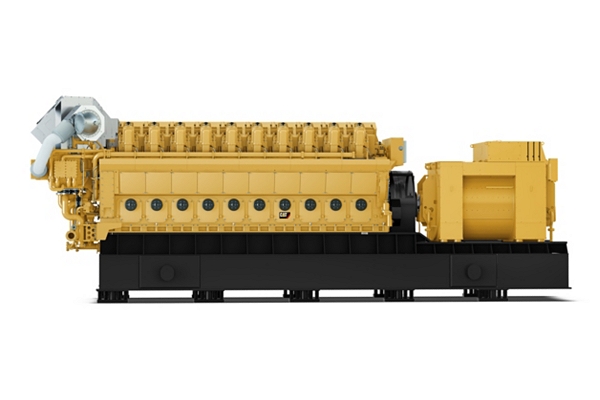

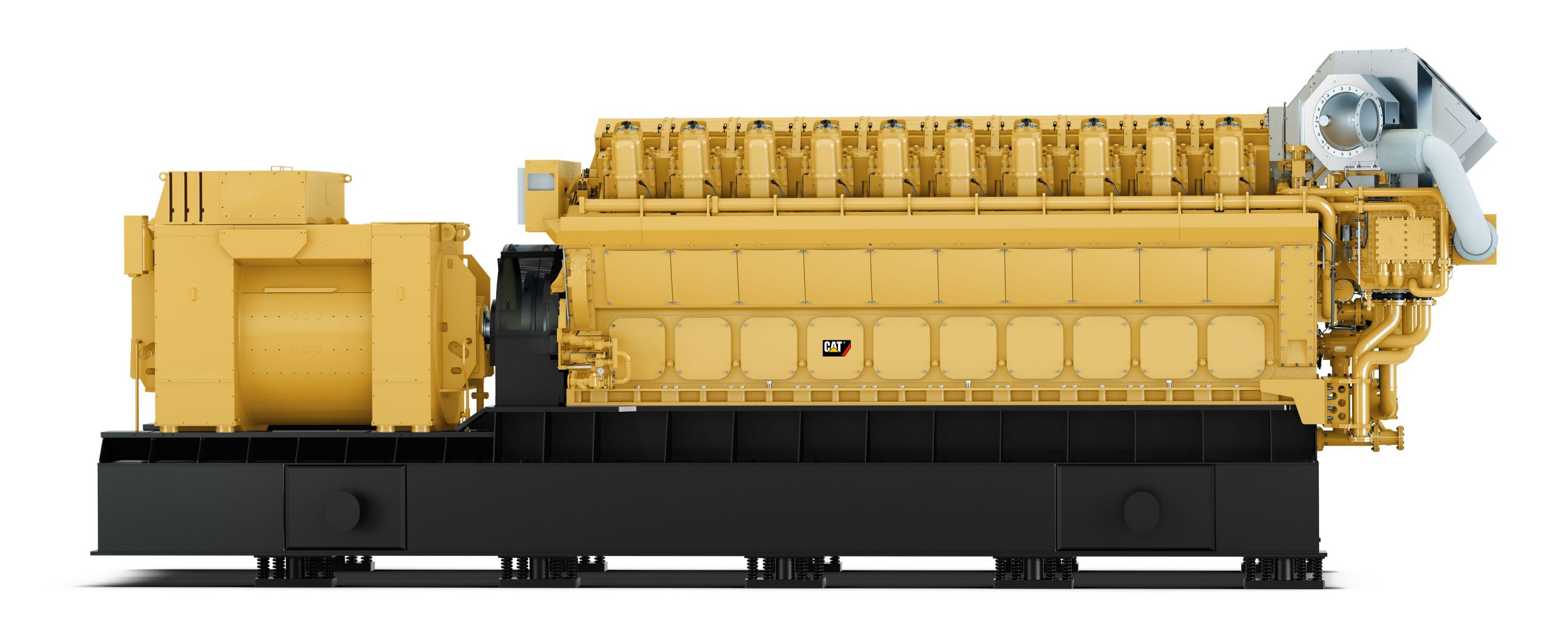

G20CM34

-

GEP218-3

-

GEP125-1

-

GEP169-1

-

G70LG2 Gas Generator Set

-

G80LG6 Gas Generator Set

-

GEP100-1

-

G45LG2 Gas Generator Set

-

GEUG16-1 Gas Generator Set

-

G300LG6 Gas Generator Set

-

G200LG6 Gas Generator Set

-

G230LG6 Gas Generator Set

-

G25LTA2 Gas Generator Set

-

G130LG4 Gas Generator Set

-

GES550-1

-

Emergency Transfer Load manager

-

Photovoltaic Module PVC

-

Photovoltaic Module PVC

-

Photovoltaic Module PVC

-

Photovoltaic Module PVC

-

Photovoltaic Module PVT

-

XG400

-

XQ2000

-

XQE20

-

XQE30

-

XQ800

-

XQ100

-

XG400 – Natural Gas

-

550kW

-

XQP275

-

XQ1475G

-

G20CM34

-

G3406 Gas Generator Set

-

Gas Generator G3516B

-

G3520E Gas Generator Set

-

DG100-2 (3 Phase)

-

DG125-2 (3 Phase)

-

DG150-2 (3 Phase)

-

DG80-2 (Single Phase)

-

DG80-2 (3 Phase)

-

DG100-2S (Single Phase)

-

DG60-2 (Single Phase)

-

DG60-2 (3 Phase)

-

DG400-2 (Single-phase)

-

DG50-2 (Single Phase)

-

DG50-2 (3 Phase)

-

DG250-2 (Single-phase)

-

DG275-2 (Single-phase)

-

DG350-2 (Single-phase)

-

DG230-2 (Single phase)

-

CG132-12 Gas Generator Set

-

Gas Generator CG132

-

G3508A

-

CM32E

-

CM43C (Inline)

-

CM46DF (V-Type)

-

CM32C (Inline) Generator Set

-

CM32C (V-Type) Generator Set

-

CM25E Generator Set

-

DE800 GC

-

3516C Generator Set

-

C15 Tier 4 Interim

-

C27 Tier 4 Interim

-

3516E High Voltage Generator Set

-

C32 Generator Set with Upgradeable Packaging

-

3516B (50 Hz) with Upgradeable Package

-

MX150 Microprocessor Controller

-

MX250 Microprocessor Controller

-

MX350 Controller

-

CTS Series Automatic Transfer Switch

-

CTX Series Automatic Transfer Switch

-

CTSM and CTGM Series Manual Transfer Switches

-

CTE Series Automatic Transfer Switch

-

CTGSE & CTGDSE Series Service Rated Entrance Rated Automatic Transfer Switch

-

CTG Series Automatic Transfer Switch

-

ATC Power Breaker Bypass Isolation Open/Closed Transition Automatic Transfer Switch

-

ATC Service Entrance Rated MCCB & Power Breaker Based ATS

-

ATC-800 CONTROLLER

-

ATC-300+ CONTROLLER

-

ATC Contactor-Based Automatic Transfer Switch

-

ATC Molded Case Circuit Breaker & Molded Case Switch Automatic Transfer Switch

-

ATC Power Breaker & Case Switch Automatic Transfer Switch

-

Cat Customizable Switchgear and Controls

-

Cat Switchgear

-

ATC Contactor Based Bypass Isolation Automatic Transfer Switch

-

Cat EGP Switchgear

-

Cat XLM Switchgear

-

EMCP 4.4 Master Control Panel

-

Engine Paralleling and Integration Control (EPIC)

-

XES60 (60 Hz)

-

XES120 (50 Hz)

-

XES120 (60 Hz)

-

Cat® BDP1000 Bi-Directional Power Inverter

-

XES60 (50 Hz)

-

Power Grid Stabilization (PGS) module

-

Energy Capacity Expansion (ECE) module

-

Power Grid Stabilization (PGS) Heavy Duty mobile module

-

Energy Time Shift (ETS) Module

-

Temporary Connection Boxes

-

XQ2280 Tier 4 Final

-

XQC1600

-

XGC1900

-

XGC1900

-

XQ1140 T4 Final – Diesel

-

XQP1100 Rental Generator Set

-

XQC1200

-

XQP500

-

XQ570 Tier 4 Final – 455 ekW (568 kVA)

-

XQP550 EU Stage V

-

XQ425

-

XQP310 EU Stage V

-

XQ330 Tier 4 Final (264 ekW, 330 kVA)

-

XQP300

-

XQ230 Rental Power

-

XQP200 EU Stage V

-

XQ125 Rental Power

-

XQP150

-

XQP115 EU Stage V

-

XQP100

-

XQP60

-

XQ60

-

XQ35

-

XQP30 – Diesel

-

CG260-16 Gas Generator Set

-

XQP20 EU Stage V

-

CG260 Gas Generator Set

-

CG170-20B Gas Generator Set

-

CG260-16 Gas Generator Set

-

CG170 Gas Generator Set

-

CG170-20 Gas Generator Set

-

CG170B-16 Gas Generator Set

-

CG170 Gas Generator Set

-

CG170B-12 Gas Generator Set

-

CG170-12 KGas Generator Set

-

CG170-12 Gas Generator Set

-

CG132B-12 Gas Generator Set

-

Gas Generator CG132B-16

-

Gas Generator CG132B-16

-

G3520H Gas Generator

-

CG132B-8 Gas Generator Set

-

Cat G3520H Combined Heat and Power (CHP) Solution

-

G3520C Gas Generator

-

G3520 2000kW Gas Generator Set

-

G3520 2500kW Gas Generator Set

-

Gas Generator G3516H

-

Cat G3516H Combined Heat and Power (CHP) Solution

-

G3516 1500kW Gas Generator Set

-

Gas Generator G3516A

-

G3516C Gas Generator Set

-

Cat G3512H Combined Heat and Power (CHP) Solution

-

G3512E Gas Generator Set

-

G3512 1000kW Gas Generator Set

-

Gas Generator G3512H

-

G3412 Gas Generator Set

-

G3512 750kW Gas Generator Set

-

G3412 Gas Generator Set

-

DG450-2 (Single-phase)

-

DG500 (3-Phase)

-

DG450 (3-Phase)

-

DG400-2 (Three phase)

-

DG350 (3-Phase)

-

DG400 (3-Phase)

-

DG275-2 (3 phase)

-

DG300-2 (3 phase)

-

DG350-2 (Single-phase)

-

DG200-2 (3 phase)

-

DG200-2S (Single-phase)

-

DG230-2 (3 phase)

-

DG250-2 (3 phase)

-

DG175-2 (Single-phase)

-

DG175-2 (3 phase)

-

DG150 (3 phase) (60 Hz)

-

C280-16 Generator Set (Medium Speed)

-

DG100 (60 Hz)

-

DG125 (Single-phase and 3 phase) (60 Hz)

-

3616 Generator Set (Medium Speed)

-

C280-12 Generator Set (Medium Speed)

-

3616 Generator Set (Medium Speed)

-

3612 Generator Set (Medium Speed)

-

C280-8 Generator Set (Medium Speed)

-

3612 Generator Set (Medium Speed)

-

3608 Generator Set (Medium Speed)

-

C280-6 Generator Set (Medium Speed)

-

3608 Generator Set (Medium Speed)

-

3606 Generator Set (Medium Speed)

-

C175-20

-

3606 Generator Set (Medium Speed)

-

C175-16 Tier 4 Final

-

C175-16 Generator Set

-

C175-20

-

3516E Low Voltage Generator Set

-

3516E Generator Set

-

C175-16 Generator Set

-

3516E Low Voltage Generator Set

-

3516C Tier 4 Final

-

3516E Low Voltage Generator Set

-

3516E Generator Set

-

3516C Generator Set

-

3516C (50 Hz) with Upgradeable Package

-

3516C Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516B (60 Hz) with Upgradeable Package

-

3516B Generator Set

-

3516B (50 Hz) Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516B Generator Set

-

3516 Diesel Generator Set

-

3516 Diesel Generator Set

-

3516B (50 Hz) India Market Only

-

3516 Diesel Generator Set

-

3512C Generator Set

-

3516 Diesel Generator Set

-

3512B Diesel Generator Set

-

3512C Generator Set

-

3512B Diesel Generator Set

-

3512B Diesel Generator Set

-

3512B (50 Hz) Generator Set

-

3512B Diesel Generator Set

-

3512 with Upgradeable Package

-

3512B (50 Hz) India Market Only

-

3512B (50 Hz) Generator Set

-

3512 Generator Set

-

3512 Generator Set

-

C32 (60 Hz)

-

3512 Generator Set

-

DE1250S GC

-

DE1500 GC

-

D1250 GC

-

DE1250 GC (50 Hz)

-

DE1400 GC

-

D1000 GC

-

DE1100 GC

-

C32 Generator Set

-

C27 Generator Set

-

C32 (50 Hz) India Market Only

-

DE1000S GC

-

DE800S GC

-

3412C Generator Set

-

C18 Generator Set

-

3412C Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

D600 GC (60 Hz) Generator Set

-

DE715 GC Generator Set

-

C18 Generator Set

-

C18 Generator Set

-

DE600S GC Generator Set

-

C18 Generator Set

-

D550 GC (60 Hz) Generator Set

-

C18 (50 Hz) India Market Only

-

DE550S GC (60 Hz) Generator Set

-

DE605 GC (50 Hz) Generator Set

-

DE660 GC (50 Hz) Generator Set

-

C15 Generator Set

-

C15 Generator Set

-

D500 GC (60 Hz) Generator Set

-

D450 GC (60 Hz) Generator Set

-

DE450S GC (60 Hz) Generator Set

-

DE500S GC (60 Hz) Generator Set

-

DE550 GC (50 Hz) Generator Set

-

C15 Generator Set

-

C15 (50 Hz) China Non Road

-

C13 Generator Set

-

C15 (50 Hz) India Market Only

-

C13 Generator Set

-

D400 GC (60 Hz) Generator Set

-

DE500 GC (50 Hz) Generator Set

-

C13 Generator Set

-

DE450 GC (50 Hz) Generator Set

-

C13 (50 Hz) China Non Road

-

D350 GC (60 Hz) Generator Set

-

DE400 GC Generator Set

-

C13 (50 Hz) India Market Only

-

C9 Generator Set

-

C9 Generator Set

-

DE400S GC Generator Set

-

D300 GC (60 Hz) Generator Set

-

DE350S GC Generator Set

-

C9 Generator Set

-

C7.1 Generator Set

-

D200 GC Generator Set

-

D250 GC (60 Hz) Generator Set

-

C7.1 ACERT

-

C7.1 ACERT

-

DE220 GC (50 Hz) Generator Set

-

D175 GC Generator Set

-

DE218AE0 (60 Hz) Generator Set

-

DE200 GC Generator Set (60 Hz)

-

DE169AE0 (60 Hz) Generator Set

-

DE218AE0 (50 Hz) Generator Set

-

DE200 GC Generator Set (50 Hz)

-

DE165 GC Generator Set (60 Hz)

-

D150 GC Generator Set

-

DE165 GC Generator Set (50 Hz)

-

DE150 GC Generator Set (60 Hz)

-

D125 GC Generator Set

-

DE150 GC Generator Set (50 Hz)

-

DE169AE0 (50 Hz) Generator Set

-

C4.4 Generator Set

-

C4.4 Generator Set

-

C4.4 Generator Set

-

D100 GC Generator Set

-

DE125AE0 (50 Hz) Generator Set

-

DE110 GC Generator Set (60 Hz)

-

DE125AE0 (60 Hz) Generator Set

-

DE100AE0 (60 Hz) Generator Set

-

DE88 GC Generator Set (60 Hz)

-

DE110 GC Generator Set (50 Hz)

-

C4.4 Generator Set

-

D80 GC Generator Set

-

DE88 GC Generator Set (50 Hz)

-

DE100AE0 (50 Hz) Generator Set

-

C3.3 Generator Set

-

D60 GC Generator Set

-

DE65 GC Generator Set (60 Hz)

-

DE65 GC Generator Set (50 Hz)

-

C3.3 Generator Set

-

DE75AE0 (60 Hz) Generator Set

-

D50 GC Generator Set

-

DE56AE0 (60 Hz) Generator Set

-

DE55 GC Generator Set (60 Hz)

-

DE75AE0 (50 Hz) Generator Set

-

D40 GC Generator Set

-

DE55 GC Generator Set (50 Hz)

-

DE50 GC Generator Set (60 Hz)

-

DE33 GC Generator Set (50 Hz)

-

DE33 GC Generator Set (60 Hz)

-

DE56AE0 (50 Hz) Generator Set

-

DE50 GC Generator Set (50 Hz)

-

C2.2 | D25 Generator Set

-

C2.2 | D30 Generator Set

-

C2.2 | D20 Generator Set

-

C1.5 Generator Set

-

C2.2 Generator Set

-

C2.2 Generator Set

-

C1.1 Generator Set

-

C1.1 Generator Set

-

C1.5 Generator Set

-

XQ 500

-

XQ 800

-

XQ 200

-

XQ1500

-

XQ1000

-

XQ400

-

XQ350

-

XQ300

-

XQ230

-

APS150

-

XQ100

-

XQ30

-

XQ2000

Overview

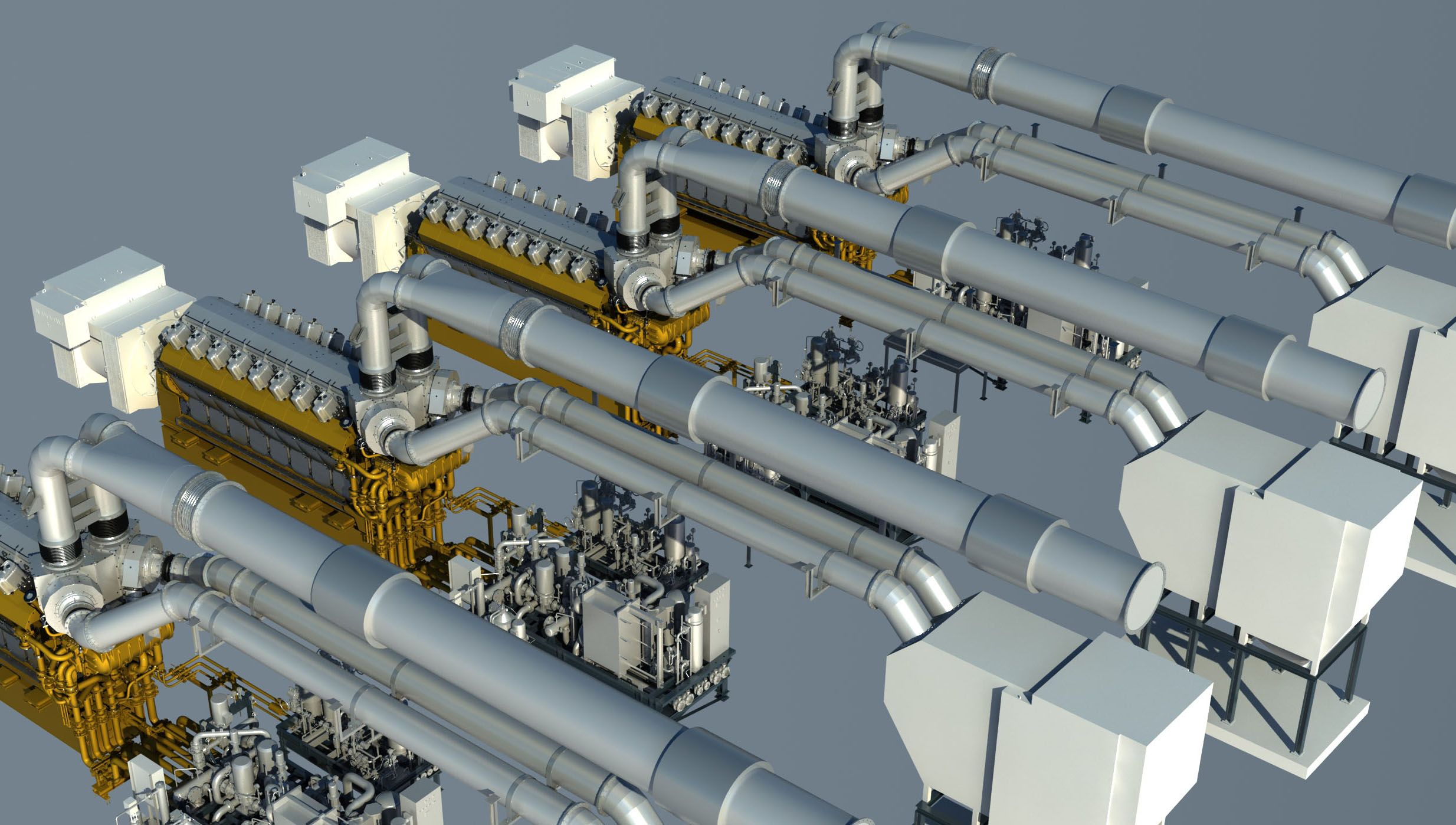

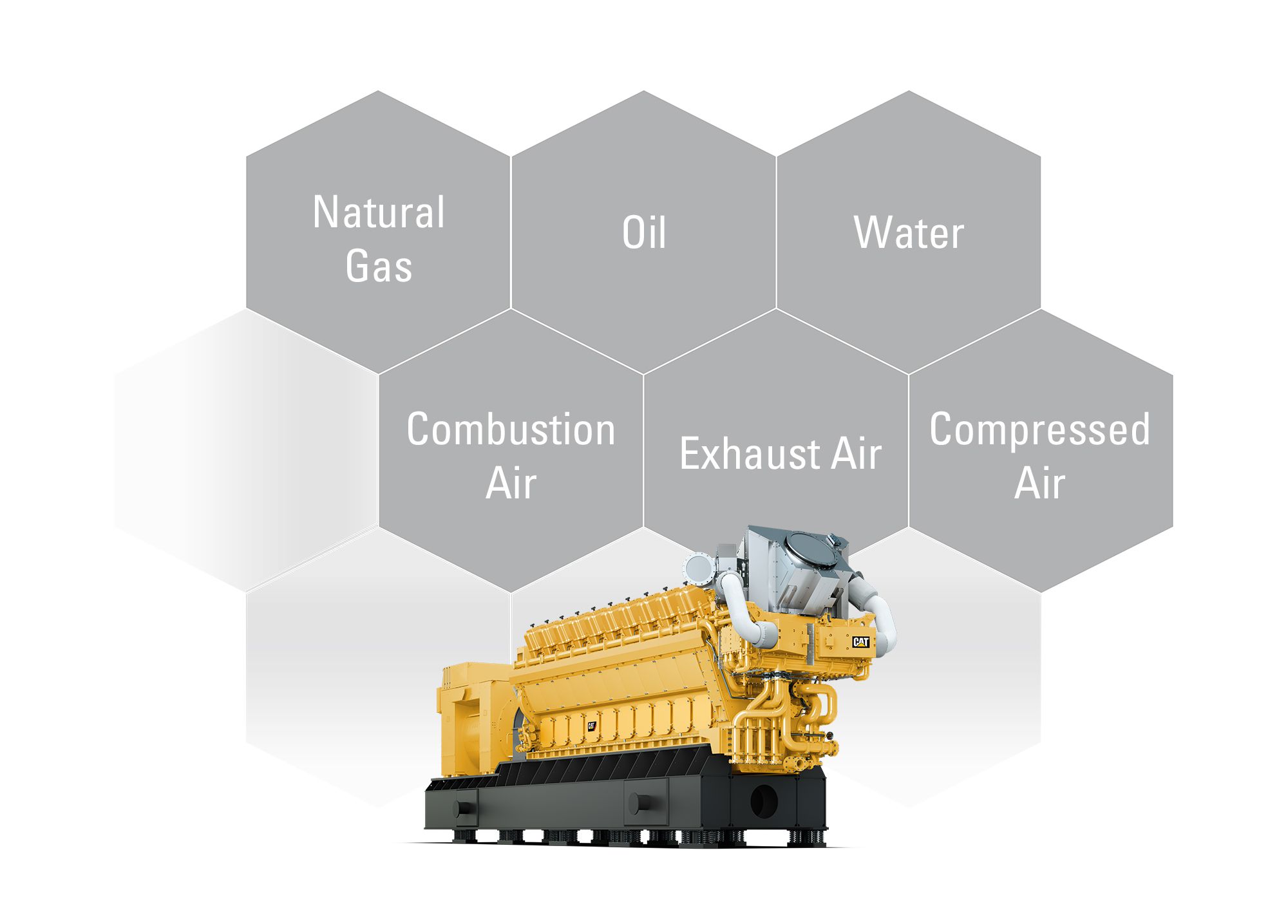

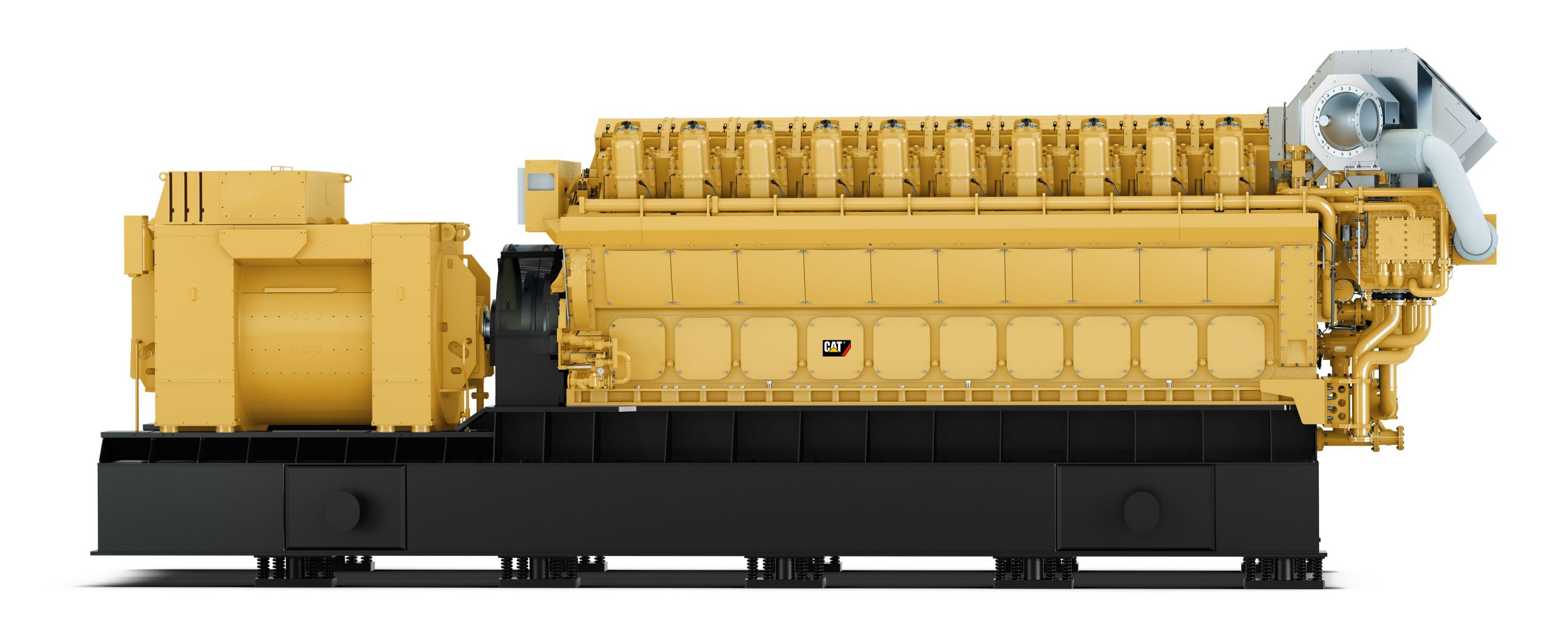

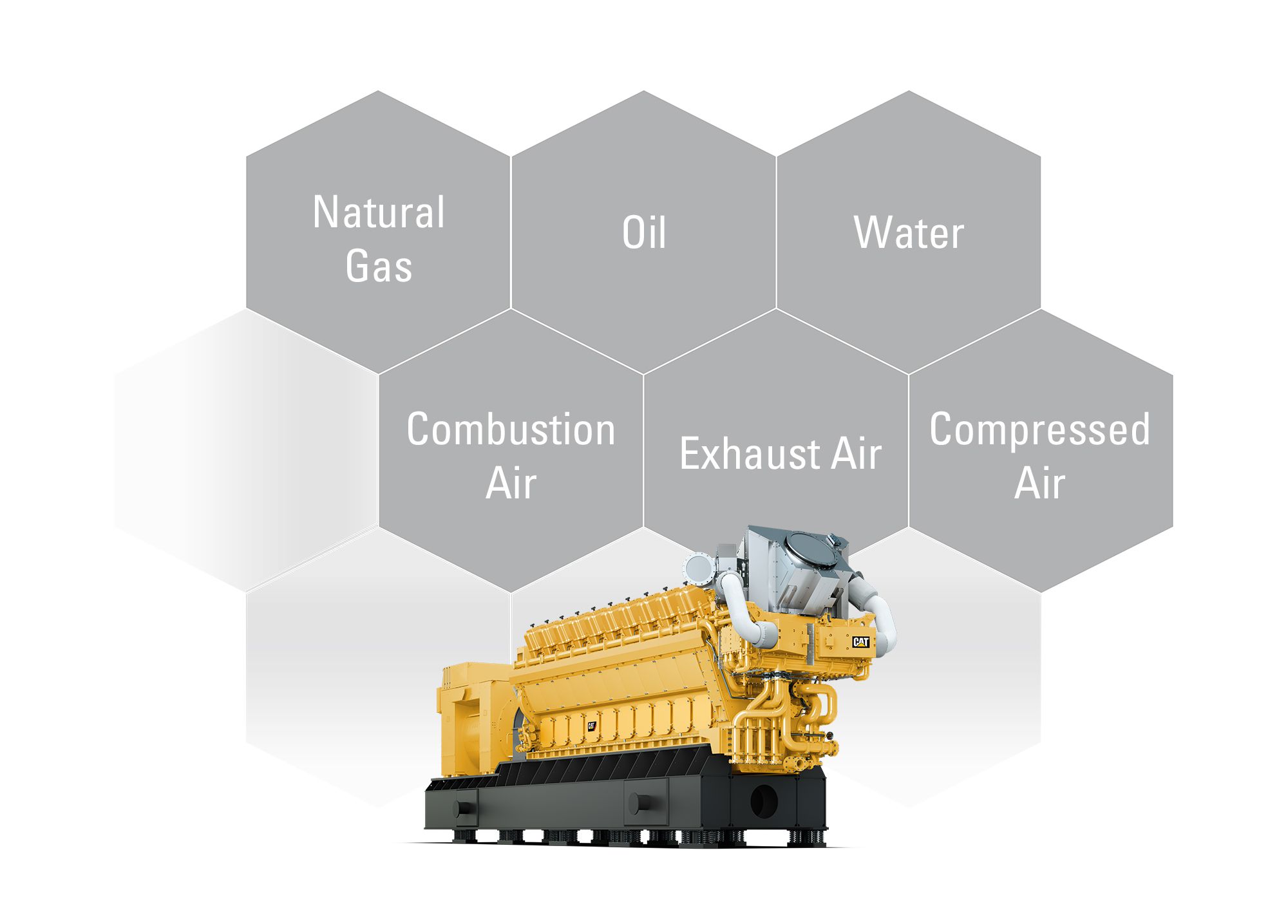

The G20CM34 is a spark ignited engine operating according to the lean burn combustion system. The use of a pre-chamber operated by means of a spark plug enables a combustion at high efficiency and low emissions. The cylinder-pressure based engine management of the G20CM34 enables engine operation at the efficiency optimum. The single-stage turbocharged, charge air cooled 20 cylinder engine reaches an electrical efficiency of up to 48 % and an overall efficiency of up to 93 %. Two charge air coolers allow a maximum utilization of the available displacement. A two-circuit cooling water system ensures flexibility. With a high temperature (HT) and a low temperature (LT) stage each, individual configurations for high altitudes of installation, high intake air temperatures, and natural gases with varying methane numbers are available. Depending on the requirements, these configurations can be optimized for purely electric power generation and combined heat and power. Stable engine operation at varying natural gas qualities is ensured by means of cylinder-specific knocking detection and continuous NOx control. An optimum material design (as e.g. the flow-optimized gas supply in the cylinder head) ensures a long service life of the components. Low fuel and lubricating oil consumption as well as low maintenance effort cater for high availability and cost efficiency of the engine.

- Genset Details

- Fuel Flexibility

- Customization

- Modular scope of supply

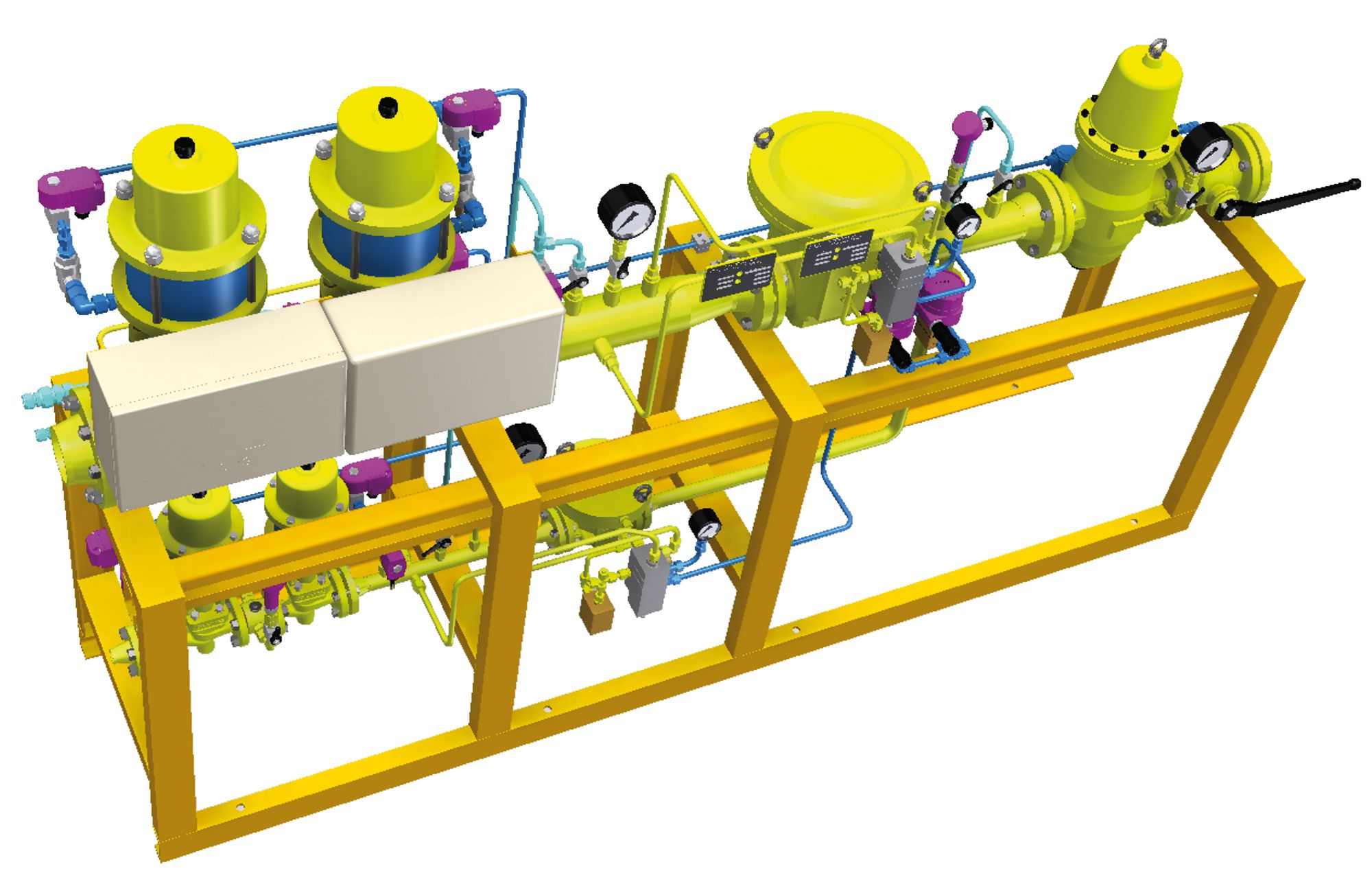

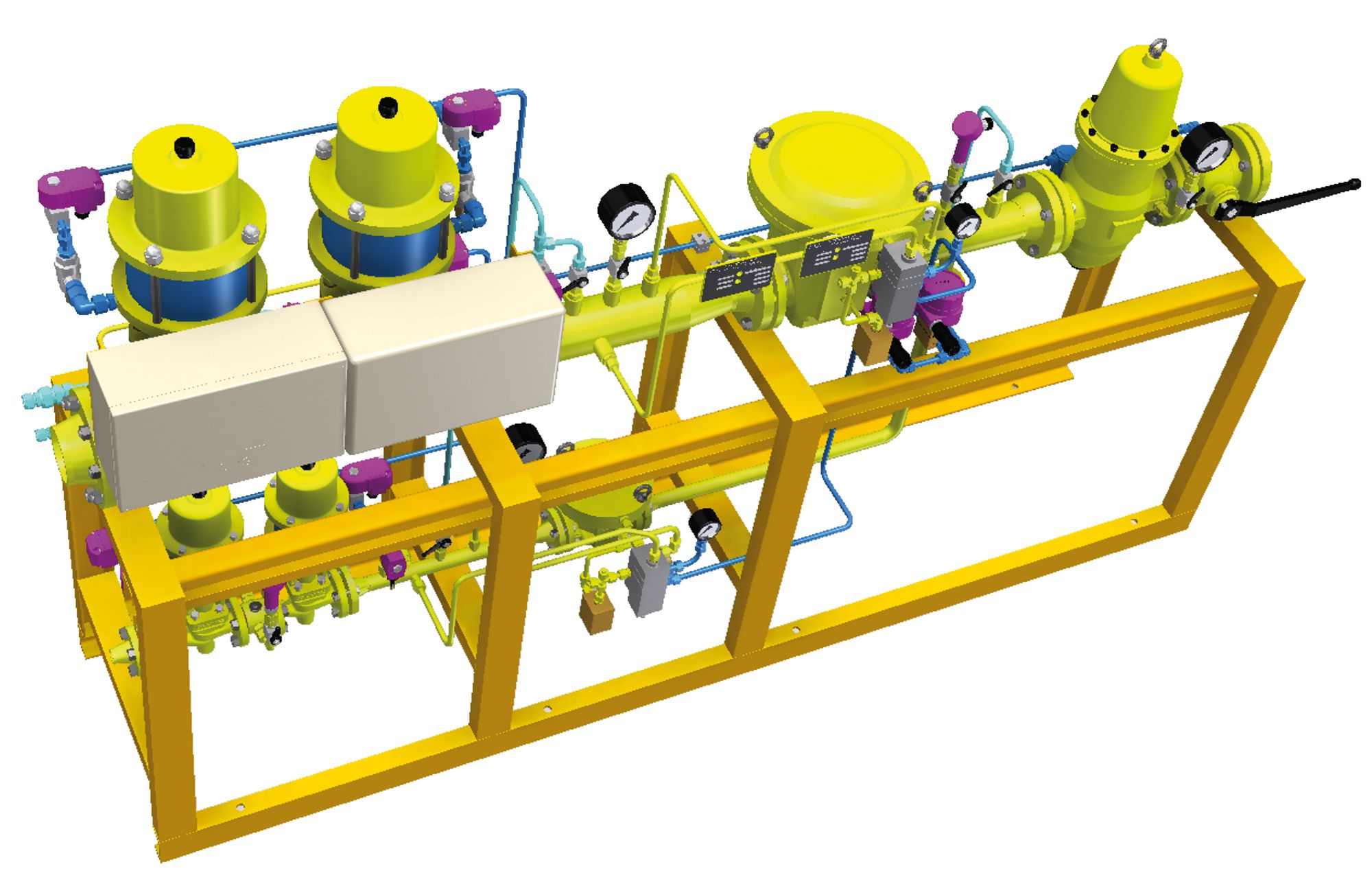

- Gas Valve Unit

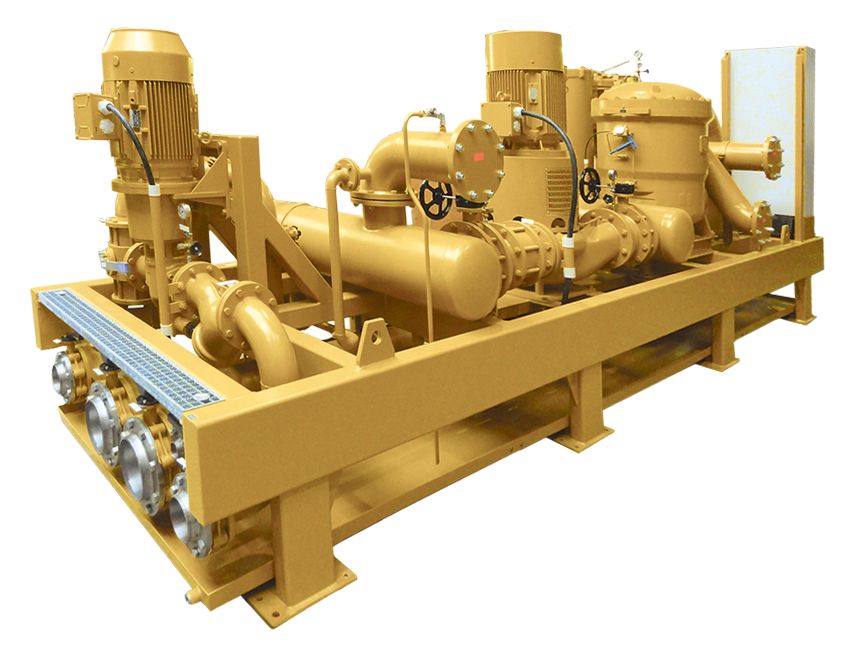

- Cooling water and lube oil combined module

- World Wide Product Support

- Spark ignited lean burn natural gas engine

- Electric power output with 10300 / 9830 ekW at 50 / 60 Hz application

- Medium-speed engine concept with high efficiency up to 48.9 %

- Designed for open cycle, base- and peak load as well as CHP application

- Wide operating ranges with excellent load following capability and high part load efficiency

- Capability for operation with various gas qualities

- Variable configuration for natural gas with diverse methan number

- Withstand the most challenging conditions and is thus offering a wide range of applications

- Maximized benefits thanks to individual, tailor-made adjustments and extensions

- Project-specific adjustment to fulfill challenging ambient conditions like high altitude and / or high temperature

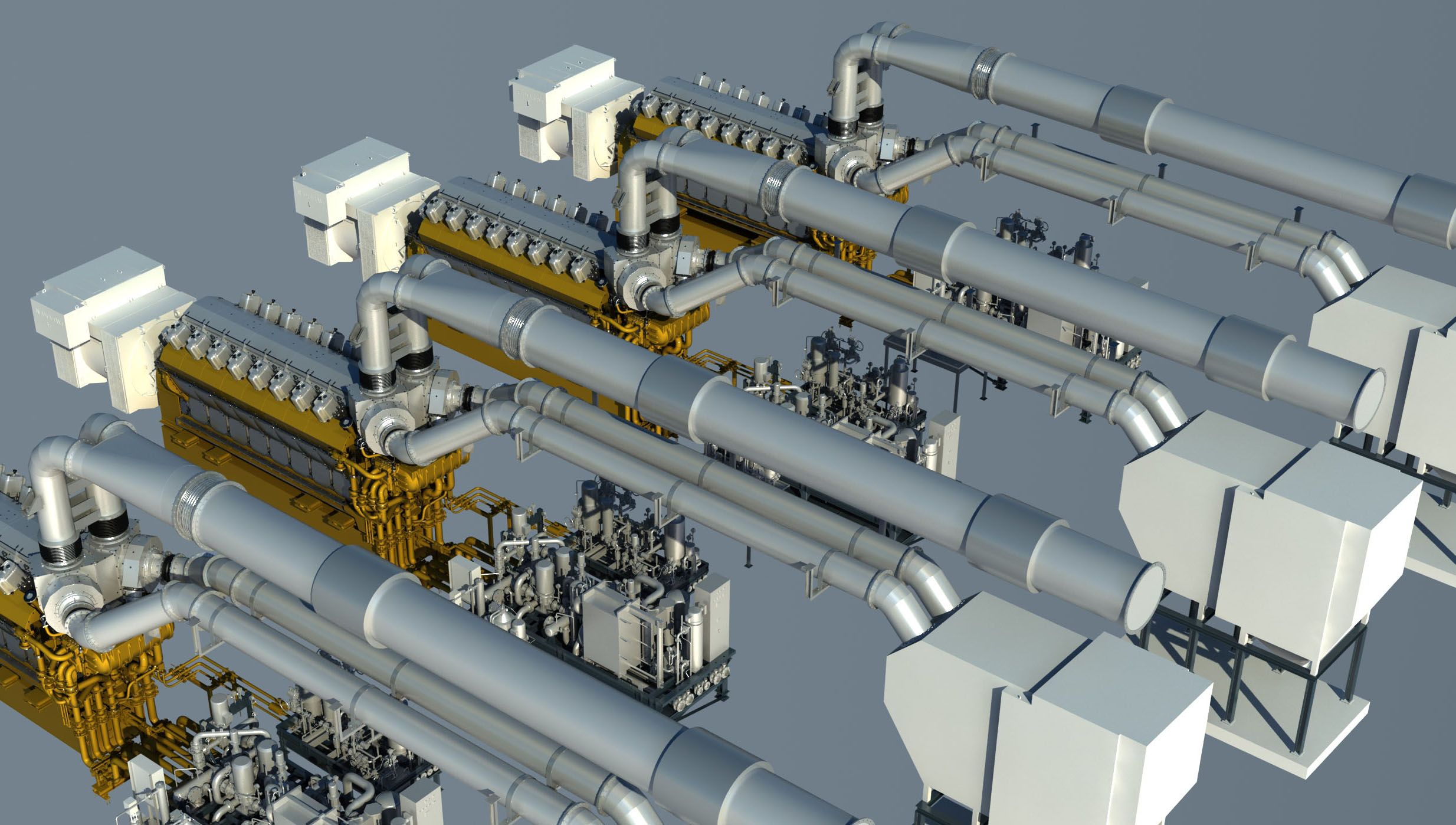

- The Caterpillar Standard Scope of Supply ensures maximum safety, best performance and excellent service capability for your Power Plant with our Gensets. Operational reliability creates a safe working environment for your employees based on our knowledge and experience, combined with the high quality of the selected components. We enable lowest fuel consumption due to an outstanding engine design as well as highest uptime through reliable power output. If you choose the Caterpillar standard scope of supply, our experienced team is capable to support you immediately remote and on site. With our Caterpillar optional scope, you can also get a wide range of auxiliaries for your power plant, convenient and fully compatible

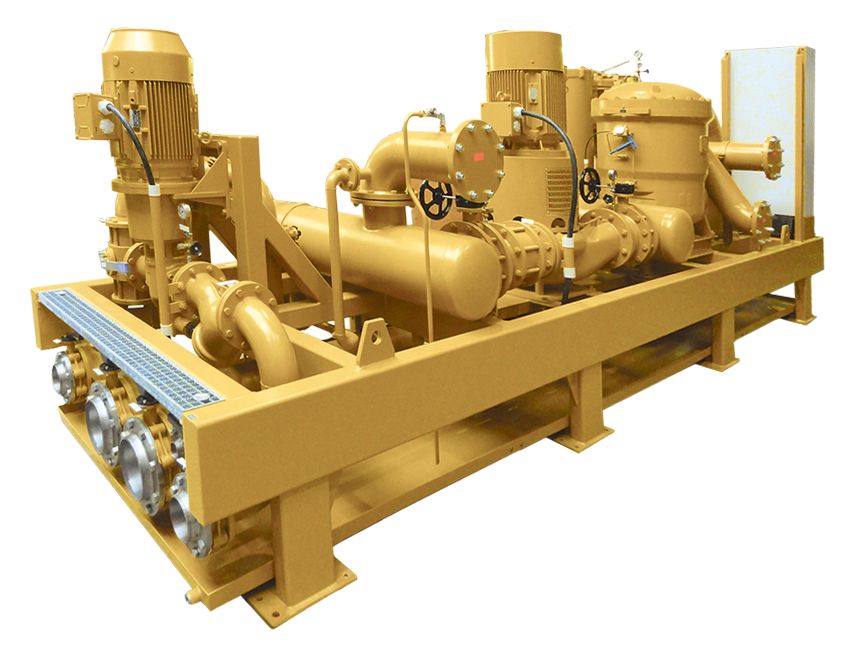

- The GVU is a stand-alone auxiliary and regulates the gas supply under all required conditions for engine operation. It is designed for natural gas operation and is therefore equipped with special safety devices. Within the GVU, the incoming natural gas is separated into ignition and main gas. Special sensors and valves enable the pressure and leakage detection to shut-off both lines. The equipment of the gas valve unit shown in the picture above is the variant according to European standard.

- The combined module includes the main components of the cooling water system and the lube oil system and is located in the power house. It provides the engine with a sufficient amount of cooling water and conditioned lube oil. The selection of the appropriate module is made by Caterpillar Motoren GmbH & Co. KG. To prevent contamination from expanding, each engine is equipped with its own combined module.

- Training Center: Get the most out of your engine while we are focusing on your individual requirements. We provide a customized engine training for customer and dealer personnel which will help you to get a competent knowledge about the engine, its components and maintenance procedures.

- The Engine Training Center is located at the Caterpillar Motoren facility in Kiel – modernized and reopened in 2011. The training classes are conducted for up to eight customers, so you have the best efficiency in learning. Several classrooms and all current engine types and technologies are available – for both theoretical as well as hands-on training.

- Spark ignited lean burn natural gas engine

- Electric power output with 10300 / 9830 ekW at 50 / 60 Hz application

- Medium-speed engine concept with high efficiency up to 48.9 %

- Designed for open cycle, base- and peak load as well as CHP application

- Wide operating ranges with excellent load following capability and high part load efficiency

- Compliance with World Bank Emission Certificate according to IFC-2008 without additional exhaust gas aftertreatment

- Compliance with MCPD 2015/2193/EU, IED according to 2010/75/EU, and 13th and 44th BImSchV by using SCR and oxidation catalyst

- Capability for operation with various gas qualities

- Variable configuration for natural gas with diverse methan number

- Withstand the most challenging conditions and is thus offering a wide range of applications

- Maximized benefits thanks to individual, tailor-made adjustments and extensions

- Project-specific adjustment to fulfill challenging ambient conditions like high altitude and / or high temperature

- The Caterpillar Standard Scope of Supply ensures maximum safety, best performance and excellent service capability for your Power Plant with our Gensets. Operational reliability creates a safe working environment for your employees based on our knowledge and experience, combined with the high quality of the selected components. We enable lowest fuel consumption due to an outstanding engine design as well as highest uptime through reliable power output. If you choose the Caterpillar standard scope of supply, our experienced team is capable to support you immediately remote and on site. With our Caterpillar optional scope, you can also get a wide range of auxiliaries for your power plant, convenient and fully compatible

- The GVU is a stand-alone auxiliary and regulates the gas supply under all required conditions for engine operation. It is designed for natural gas operation and is therefore equipped with special safety devices. Within the GVU, the incoming natural gas is separated into ignition and main gas. Special sensors and valves enable the pressure and leakage detection to shut-off both lines. The equipment of the gas valve unit shown in the picture above is the variant according to European standard.

- The combined module includes the main components of the cooling water system and the lube oil system and is located in the power house. It provides the engine with a sufficient amount of cooling water and conditioned lube oil. The selection of the appropriate module is made by Caterpillar Motoren GmbH & Co. KG. To prevent contamination from expanding, each engine is equipped with its own combined module.

- Training Center: Get the most out of your engine while we are focusing on your individual requirements. We provide a customized engine training for customer and dealer personnel which will help you to get a competent knowledge about the engine, its components and maintenance procedures.

- The Engine Training Center is located at the Caterpillar Motoren facility in Kiel – modernized and reopened in 2011. The training classes are conducted for up to eight customers, so you have the best efficiency in learning. Several classrooms and all current engine types and technologies are available – for both theoretical as well as hands-on training.

- REParts Center: In addition to the traditional spare parts business, we also offer a broad portfolio of value-added after-sales services, including the reconditioning of wear parts. This enables you to operate your equipment even more efficiently.

- Rebuilding MaK genuine parts enables a second life, adding value to your investment and reducing overall owning and operating costs. Through our new MaK Repair and Exchange Parts program, we are able to offer our customers extensive repair and exchange options, which provide same-as-new performance and reliability at a fraction of new price. The results are maximum engine productivity and lower life cycle costs –while reducing the impact on the environment.

Generator Set Specifications

- Continuous Rating

- 9830 / 10300 ekW @ 0.8 pf

- Fuel Type

- Natural Gas

- Maximum Electrical Efficiency

- 48.90%

- Frequency

- 50 / 60 Hz

- RPM

- 750/720

- Frequency

- 50/60 Hz

Engine Specifications

- Engine Model

- G20CM34

- Displacement

- 46484.2in³

- Aspiration

- Turbocharged and Aftercooled

- Bore

- 13.38in

- Stroke

- 16.53in

Generator Set Dimensions

- Length

- 562.2in

- Width

- 153.9in

- Height

- 212.2in

- Dry Weight - Genset

- 361559lb

Standard/Optional Features

Standard Equipment:

-

- Safety

-

- Crankcase ventilation

- Oil mist detector

-

- Fuel System

-

- Gas valve unit (GVU)

-

- Combined Module

-

- Cooling water- and lubricating oil system partly on a common base frame with standardized pipe interface. (Cooling water system requires additional cooling towers, radiators or similar)

-

- Intake Air

-

- Systems that can be adjusted to suit the ambient conditions are available, such as pocket filters, oil bath filters or pulse filters

-

- Starting Air

-

- Starting air compressor module

- Starting air receiver module

-

- Exhaust Gas

-

- Exhaust gas ventilation module

- Exhaust gas silencer

- Further elements, such as SCR and oxidation catalyst, are available as options

-

- Control & Monitoring System

-

- Provides the control, monitoring and protection functions of the engine, generator and engine support modules through:

- Local Control Panel (LCP) (recommended) or

- Local Data Panel (LDP) and Generator Control Panel (GCP)

- Provides the control of the engine support modules through Motor Control Center (MCC)

- Asset Intelligence System: Your remote diagnostic system, worldwide

- Provides the control, monitoring and protection functions of the engine, generator and engine support modules through:

-

- Vibration Damping

-

- Optimum oscillation and vibration damping systems for safe and operationally reliable set-up of the plant, especially adjusted to suit your ambient conditions.

- Engine and generator can be supplied as a unit on a common base frame

Optional Equipment: