315 Hydraulic Excavator

Excavators

Mini Excavators (23)

-

305E2 CR Mini Hydraulic Excavator

-

305.5E2 CR Mini Hydraulic Excavator

-

303E CR Mini Hydraulic Excavator

-

304E2 CR Mini Hydraulic Excavator

-

303.5E2 CR Hydraulic Excavator

-

309 CR Mini Hydraulic Excavator

-

309 CR VAB Mini Hydraulic Excavator

-

310 Mini Hydraulic Excavator

-

308 CR Mini Hydraulic Excavator

-

307.5 Mini Hydraulic Excavator

-

308 CR VAB Mini Hydraulic Excavator

-

305 CR Mini Hydraulic Excavator

-

304 Mini Excavator

-

306 CR Mini Hydraulic Excavator

-

303.5 CR Mini Hydraulic Excavator

-

303 CR Mini Hydraulic Excavator

-

302.7 CR Mini Hydraulic Excavator

-

302 CR Mini Hydraulic Excavator

-

301.7 CR Mini Hydraulic Excavator

-

301.8 Mini Hydraulic Excavator

-

301.5 Mini Hydraulic Excavator

-

300.9D Mini Hydraulic Excavator

-

300.9D VPS & HPU300 Mini Hydraulic Excavator

Small Excavators (6)

-

317 GC Hydraulic Excavator

-

317 Hydraulic Excavator

-

315 GC Hydraulic Excavator

-

313 Hydraulic Excavator

-

315 Hydraulic Excavator

-

313 GC Hydraulic Excavator

Medium Excavators (8)

-

330 GC Excavator | 30 Ton Excavator / Digger

-

335 Hydraulic Excavator

-

326 Hydraulic Excavator

-

325 Hydraulic Excavator

-

330 Excavator | 30 Ton Excavator / Digger

-

320 Hydraulic Excavator

-

323 Hydraulic Excavator

-

320 GC Hydraulic Excavator

Large Excavators (9)

-

349F L XE Hydraulic Excavator

-

336F L XE Hydraulic Excavator

-

336 Hydraulic Excavator

-

349 Hydraulic Excavator

-

395 Excavator

-

340 Hydraulic Excavator

-

374 Hydraulic Excavator

-

352 Hydraulic Excavator

-

336 Hydraulic Excavator

Long Reach Excavation (1)

Demolition Excavators (2)

Wheel Excavators (9)

Overview

The Cat® 315 excavator offers superior performance in a compact design. Standard, easy-to-use Cat technologies boost operator efficiencies and improve jobsite productivity while a large, ergonomic cab provides a comfortable working environment. Combined with simplified maintenance points, the 315 keeps you working, quickly and efficiently.

- Latest Features

- High Performance and Productivity

- Boost Efficiency and Productivity with Cat Technologies

- Take the Guesswork out of Managing Your Equipment

- Work in Comfort

- Simple to Operate

- Lower Maintenance Costs

- Safety

- Sustainability

Latest Features

- Cab Monitor Improvements

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- Identify apps quickly with a grid list view, abbreviated app names, and categorized menu options.

High Performance and Productivity

- Increase productivity by up to eight percent over the 315F.

- Work confidently in space-restricted areas. Dig, swing, and dump within a working space of 3.96 m (12 ft 11 in).

- Easily work on slopes and move around your jobsite with 10 percent more swing torque and 14 percent more drawbar pull.

Boost Efficiency and Productivity with Cat Technologies

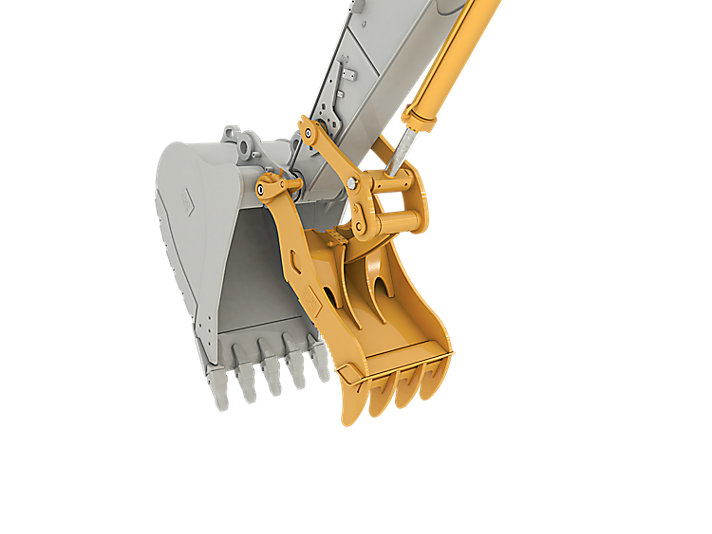

- Cat Payload helps you achieve precise load targets to improve your operating efficiency. Pick up a load of material--with a bucket and thumb combination or grapple and clamshell attachments--and get a real-time weight estimate without swinging.

- Combine Payload with VisionLink® and remotely manage your production targets.

Take the Guesswork out of Managing Your Equipment

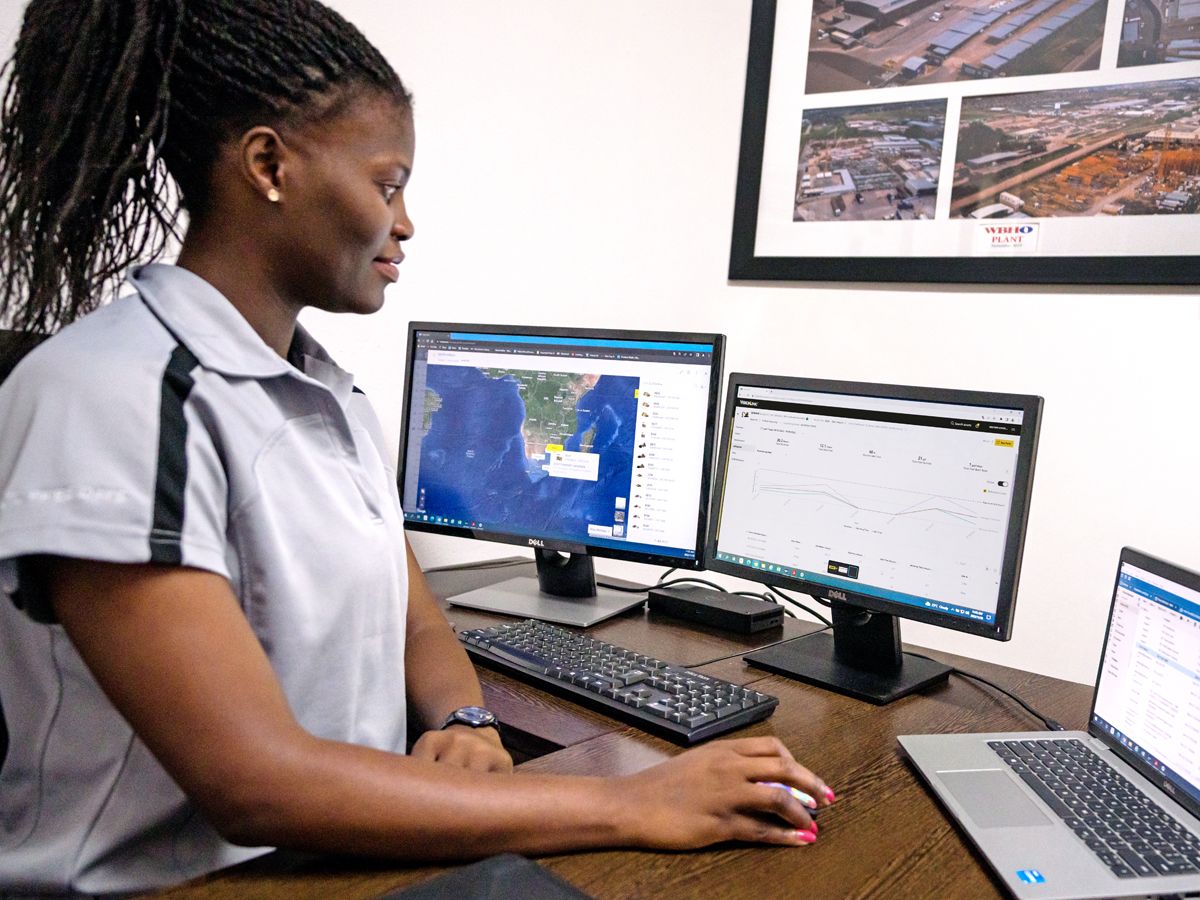

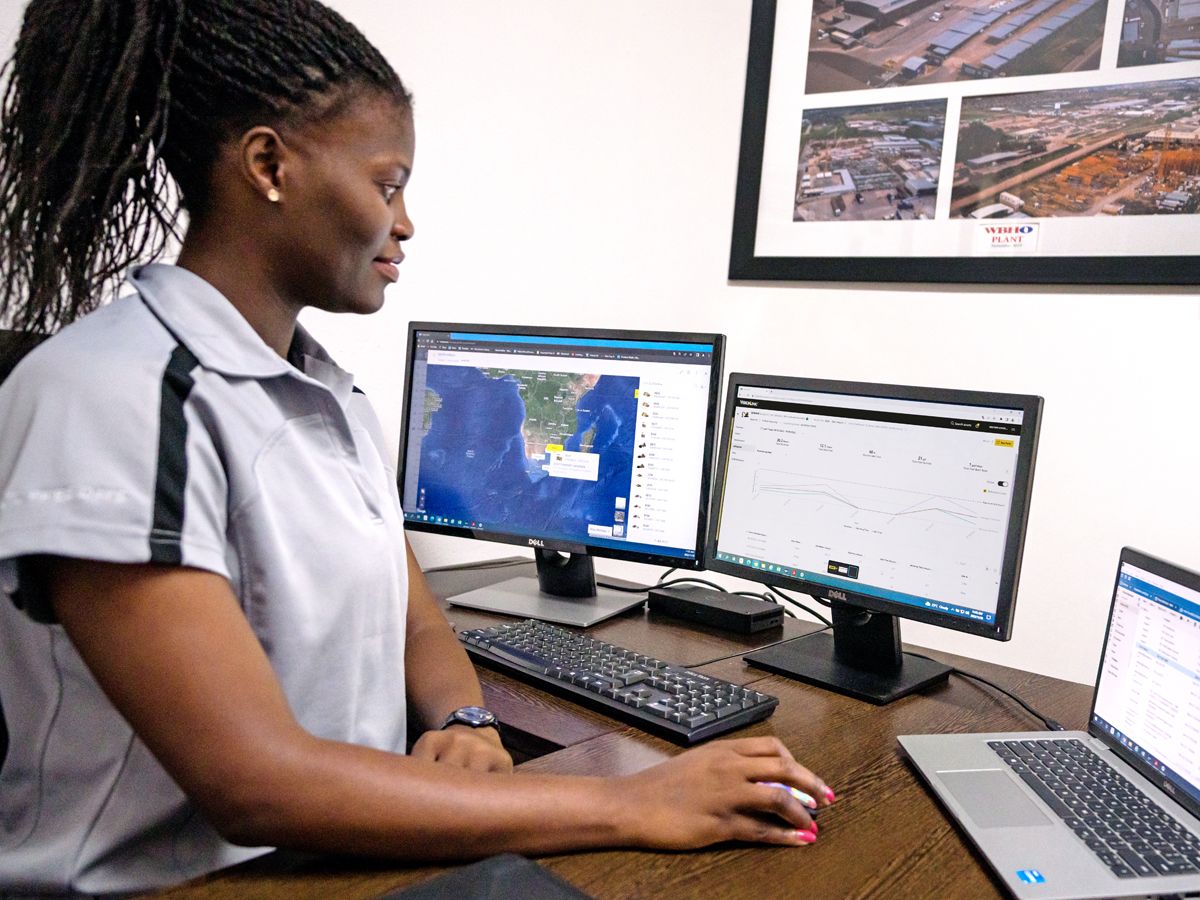

- VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer.* Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

Work in Comfort

- Increase operator productivity with an updated, 13 percent larger cab. Comfort, Deluxe, and Premium cab options vary by region.

- The Comfort cab is equipped with a mechanical suspension seat. The Deluxe seat is heated and air adjustable while the Premium seat is heated and cooled and adjusts automatically.

Simple to Operate

- Cat continues to improve user interface functionality for operators of all skill levels. The touchscreen monitor is an easy-to-use operating tool that presents the jobsite dashboard with an intuitive format. Productivity applications are displayed in grid-view to read on-the-go, and touchscreen navigation is programmed to make sure job performance continues without any hold ups.

Lower Maintenance Costs

- Expect up to 30 percent less maintenance costs than the 315F.

- Quickly check and service your machine with all daily maintenance points accessible from ground level.

- Check the engine oil level quickly and safely from the ground. Fill and check engine oil on top of the machine with a conveniently located second dipstick.

Safety

- Access all daily maintenance points from ground level – no need for you to climb on top of the machine.

- The standard ROPS cab meets ISO 12117-2:2008 requirements.

- Smaller cab pillars, larger windows, and a wider skylight hatch provide 60 percent greater vertical visibility.

Sustainability

- The Cat® C3.6 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- The 315 emits up to 8% less CO2 than the previous 315F*.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels*** up to: 20% biodiesel FAME (fatty acid methyl ester)** or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels.Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations" (SEBU6250) for details.

Latest Features

- Cab Monitor Improvements

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- Identify apps quickly with a grid list view, abbreviated app names, and categorized menu options.

- A new notification center keeps important information visible to the operator, and displays messages without shrinking the camera view.

- Color coded notifications set critical messages apart from the rest.

- Use the in-monitor QR code to learn about machine and technology features through a full suite of “how-to” videos.

- Operator Coaching is an in-cab system that recognizes specific opportunities for operators to be more productive and prevent unnecessary machine wear and tear.

- Optional Cat Detect - People Detection helps the operator avoid personnel on the jobsite with visual and auditory alerts.

- Standard integrated vehicle health management system alerts the operator with service guidance and parts needed to enhance uptime.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area. Build Number: 07E.

High Performance and Productivity

- Increase productivity by up to eight percent over the 315F.

- Work confidently in space-restricted areas. Dig, swing, and dump within a working space of 3.96 m (12 ft 11 in).

- Easily work on slopes and move around your jobsite with 10 percent more swing torque and 14 percent more drawbar pull.

- The advanced hydraulic system provides the optimum balance of power and efficiency while giving you the control you need for precise digging requirements.

- Smart mode meets your power needs by automatically matching engine and hydraulic power to digging conditions.

- Get higher production in demanding applications, easier penetration into piles, and faster cycle times with Cat® Advansys™ bucket tips. Quickly change tips with a simple lug wrench instead of a hammer or special tool, improving safety and uptime.

- Auxiliary hydraulic options give you the versatility to use a wide range of Cat attachments.

- The Cat C3.6 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 (Tier 4 Final) emission standards.

- Don’t let the temperature stop you from working. The 315 has a standard high-ambient temperature capability of 52° C (125° F) without de-rate and cold-start capability of -25° C (-13° F).

Boost Efficiency and Productivity with Cat Technologies

- Cat Payload helps you achieve precise load targets to improve your operating efficiency. Pick up a load of material--with a bucket and thumb combination or grapple and clamshell attachments--and get a real-time weight estimate without swinging.

- Combine Payload with VisionLink® and remotely manage your production targets.

- Upgrade to Cat Grade with Advanced 2D to create and edit grade designs with ease on a second, high-resolution 254 mm (10 in) touchscreen monitor.

- Want a 3D system to improve your digging results? Caterpillar's new single antenna global navigation satellite system (GNSS) makes it easy by giving you visual and auditory guidance to grade. Plus you can create and edit designs on the touchscreen monitor while you’re on the job. If your application calls for a dual antenna system, it’s easy to upgrade.

- Upgrade to our dual antenna GNSS for maximum grading efficiency. The system lets you create and edit designs on the touchscreen monitor while you’re on the job, or you can have the plan design sent to the excavator to make your work easier. Plus you get added benefits of avoidance zones, cut and fill mapping, lane guidance, and augmented reality along with advanced positioning capability.

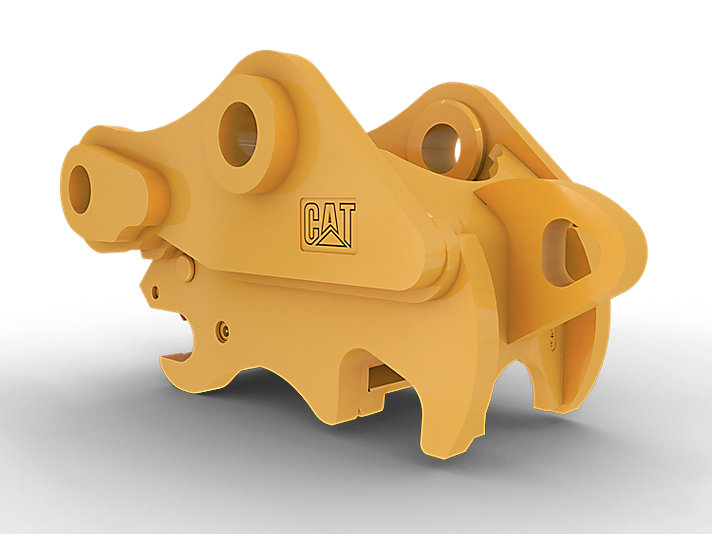

- Improve your accuracy and safety – Add a new Cat Tiltrotator system upgrade with factory-fit joysticks. The system allows a Tiltrotator to work with standard Cat 2D Grade and E-Fence; it uses the standard cab monitor to display the tool and engage its SecureLock™ so you don’t need spend money on an extra monitor.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica. Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

- Operator Coaching is an in-cab system that recognizes specific opportunities for operators to be more productive and prevent unnecessary machine wear and tear.

Take the Guesswork out of Managing Your Equipment

- VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer.* Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- VisionLink Productivity gathers and summarizes machine telematics and jobsite data from all your equipment – regardless of the manufacture.* View actionable information such as idle time, fuel burn, location, payload, load counts, total cycles, and more to improve machine efficiency, productivity, and utilization. Access data anywhere via a mobile, tablet, or desktop device - on or off the jobsite.

- Cat® Inspect is a mobile application that allows you to easily perform digital preventative maintenance (PM) checks, inspections, and daily walkarounds. Inspections can easily be integrated with other Cat data systems like VisionLink so you can keep a close eye on your fleet.

- Remote Troubleshoot is a mobile application that allows your Cat dealer to perform diagnostic testing on your connected machine remotely to help ensure that issues are resolved quickly and with less downtime.

- Remote Flash is a mobile application that allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency.

- The Cat PL161 attachment locator allows you to track attachments across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The work tool recognition feature automatically adjusts machine settings based on the selected tool.

Work in Comfort

- Increase operator productivity with an updated, 13 percent larger cab. Comfort, Deluxe, and Premium cab options vary by region.

- The Comfort cab is equipped with a mechanical suspension seat. The Deluxe seat is heated and air adjustable while the Premium seat is heated and cooled and adjusts automatically.

- Get in and out of the cab easier using the tip-up left console available in the deluxe and premium cabs.

- Advanced viscous mounts reduce cab vibration.

- Control the excavator comfortably with easy-to-reach controls all located in front of you.

- Stow your gear with plenty of in-cab storage beneath and behind the seat, overhead, and in the consoles. A cup holder, document holder, and coat hook are also provided.

- Use the standard radio’s USB ports and Bluetooth® technology to connect personal devices and make hands-free calls.

Simple to Operate

- Cat continues to improve user interface functionality for operators of all skill levels. The touchscreen monitor is an easy-to-use operating tool that presents the jobsite dashboard with an intuitive format. Productivity applications are displayed in grid-view to read on-the-go, and touchscreen navigation is programmed to make sure job performance continues without any hold ups.

- Start the engine with the push of a button, a Bluetooth key fob, or the unique Operator ID function.

- Program your preferred power mode and joystick settings using your operator ID. The excavator will automatically remember your selections.

- Navigate intuitively on the standard high-resolution touchscreen monitor with an easy-to use menu, minimizing performance interruption.

- User interface has more efficient operation with reduced number of required touch-screen interactions. Identify apps quickly with a grid list view, abbreviated app names, and categorized menu options.

- The Cat Locator is a Bluetooth device that makes finding your attachments and other gear quick and easy. The excavator’s onboard Bluetooth reader or Cat App on your phone will locate the device automatically.

- Save time and energy with work tool recognition. A simple shake of the attached tool confirms its identity ensuring all attachment settings are correct, so you can get to work quickly and efficiently.

- Not sure how a function works or how to maintain your machine? Simply access the operator’s manual through the touch screen monitor.

- Make moving the excavator much easier with Cat Stick Steer. Simply push a button and use one hand to travel and turn instead of both hands or feet on levers or pedals.

- Make operating easier with the touch of a joystick button. Additional auxiliary relays allow you to power on or turn off a CB radio, beacon light, and even a dust suppression watering system without taking your hands off the joysticks.

- Tiltrotator attachments--ours or other brands--work seamlessly with Cat 2D Grade, Assist, Payload, and E-Fence . With no additional hardware required, all you have to do is simply select "Third Party Tiltrotator System Installation" in the monitor, do the calibration, and get to work.

Lower Maintenance Costs

- Expect up to 30 percent less maintenance costs than the 315F.

- Quickly check and service your machine with all daily maintenance points accessible from ground level.

- Check the engine oil level quickly and safely from the ground. Fill and check engine oil on top of the machine with a conveniently located second dipstick.

- Track your machine’s filter life and maintenance intervals on the in-cab monitor.

- The hydraulic oil filter provides improved filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and longer life with a 3,000-hour replacement interval – 50 percent longer than previous filter designs.

- Boost productivity with proactive service reminders. The Integrated Vehicle Health Management system alerts the operator with step-by-step service guidance along with parts needed so you don't experience any unnecessary downtime.

- S·O·SSM ports are located at ground level, simplifying maintenance and allowing for quick, easy extraction of fluid samples for analysis.

Safety

- Access all daily maintenance points from ground level – no need for you to climb on top of the machine.

- The standard ROPS cab meets ISO 12117-2:2008 requirements.

- Smaller cab pillars, larger windows, and a wider skylight hatch provide 60 percent greater vertical visibility.

- The standard hydraulic lockout lever isolates all hydraulic and travel functions in the lowered position.

- A ground-level shut-off switch stops all fuel to the engine and shuts down the machine when activated.

- A rearview and right-side-view camera are standard. Upgrade to 360° visibility to easily see objects and personnel around the excavator in a single view.

- Cat Detect - People Detection helps protect the most valuable asset on any jobsite – people. The system uses smart cameras with depth sensors to provide the operator with visual and auditory alerts so he or she can take immediate action when a person is too close to the excavator.

- An updated service platform design provides easy, safe, and quick access to the upper service platform. Prevent slipping with the anti-skid punch plate on the platform steps.

- Optional boom and stick lowering check valves prevent reverse flow, keeping your front linkage securely in place should the hydraulic system unexpectedly lose power.

- Brightly colored seatbelts allow easy recognition of properly utilized safety restraints.

- Enhance jobsite safety by adding Cat Command to your fleet. The remote control system comes with everything you need like WIFI radio, cameras, and microphone so you can work outside of the cab and avoid potential hazards.

- 2D E-Fence prevents the excavator from moving outside of operator-defined set points; the system works with thumb and bucket combinations along with hammer, grapple, and clamshell attachments.

- Make service work easier and safer with optional inspection lighting. With the flip of a switch, lights will illuminate the engine, pump, battery, and radiator compartments to enhance visibility.

- Enhance jobsite safety. Add a swing alarm to alert people when you're rotating from trench to stockpile and back again.

Sustainability

- The Cat® C3.6 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- The 315 emits up to 8% less CO2 than the previous 315F*.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels*** up to: 20% biodiesel FAME (fatty acid methyl ester)** or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels.Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations" (SEBU6250) for details.

- Cat Grade technologies combine advanced guidance with optional automated machine control helping you reach grading targets while reducing fuel burn and greenhouse gas emissions by improving efficiency, job site productivity, and accuracy.

- Auto Engine Speed Control reduces unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Cat® Payload for excavators provides on-the-go material weighing which helps reduce fuel burn by improving loading efficiency, job site productivity, and eliminating trips to the scale.

- Cat® 2D E-fence keeps the front linkage within a predefined work area to avoid hazards such as traffic - not only helping keep personnel safe but also helps you avoid repairs, downtime, and costly job site fines.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Cat VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

**Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel.***Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.8 hg of refrigerant which has a CO2 equivalent of 1.144 metric tonnes.

Working Ranges & Forces

- Stick Digging Force - ISO

- 13330lbf

- Bucket Digging Force - ISO

- 22180lbf

- Minimum Working Equipment Radius

- 7.3ft

- Maximum Vertical Wall Digging Depth

- 16.9ft

- Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

- 19ft

- Minimum Loading Height

- 6.8ft

- Maximum Loading Height

- 23.6ft

- Maximum Cutting Height

- 31.7ft

- Maximum Reach at Ground Level

- 28.5ft

- Bucket

- GD 0.53 m³ (0.69 yd³)

- Stick

- Reach R3.0 m (9'10")

- Boom

- Reach 4.65 m (15'3")

- Maximum Digging Depth

- 19.6ft

Dimensions

- Transport Width

- 8.1ft

- Track Gauge

- 6.5ft

- Length to Center of Rollers

- 9.9ft

- Track Length

- 12.3ft

- Ground Clearance

- 1.4ft

- Counterweight Clearance

- 2.8ft

- Tail Swing Radius

- 5.1ft

- Shipping Length - with Blade

- 26.5ft

- Shipping Length

- 24.7ft

- Handrail Height

- 9.3ft

- Shipping Height - Top of Cab

- 9.2ft

- Bucket

- GD 0.53 m³ (0.69 yd³)

- Stick

- Reach R3.0 m (9'10")

- Boom

- Reach 4.65 m (15'3")

Engine

- Net Power - ISO 9249

- 108HP

- Displacement

- 220in³

- Stroke

- 5in

- Bore

- 4in

- Engine Power - ISO 9249

- 108HP

- Engine Model

- Cat C3.6

- Engine Power - ISO 14396

- 110HP

- Biodiesel Capability

- Up to B20¹

- Emissions

- Meets U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 emission standards.

- Note (1)

- Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system and alternator with engine speed at 2,400 rpm. Advertised power is tested per the specified standard in effect at the time

- Note (2)

- ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO

- Net Power - ISO 9249 (DIN)

- 110hp (metric)

- Engine Power - ISO 14396 (DIN)

- 111hp (metric)

Service Refill Capacities

- DEF Tank

- 6gal (US)

- Hydraulic Tank

- 19gal (US)

- Hydraulic System - Including Tank

- 22.5gal (US)

- Final Drive - Each

- 1gal (US)

- Engine Oil

- 2gal (US)

- Cooling System

- 4gal (US)

- Fuel Tank Capacity

- 49gal (US)

Weights

- Operating Weight

- 34000lb

Swing Mechanism

- Maximum Swing Torque

- 25815ft·lbf

- Swing Speed

- 12r/min

Hydraulic System

- Maximum Pressure - Swing

- 3770psi

- Maximum Pressure - Travel

- 5075psi

- Maximum Pressure - Equipment

- 5075psi

- Main System - Maximum Flow

- 276 l/min (73 gal/min)

Sustainability

- Recyclability

- 95%

Standard/Optional Features

Standard Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Cab

-

- Rollover Protective Structure (ROPS)

-

- Cat Technologies

-

- VisionLink®

- Remote Flash

- Remote Troubleshoot

- Cat Grade with 2D

- Cat Assist

- Cat Payload

- 2D E-Fence

-

- Electrical System

-

- Maintenance free battery

- LED chassis light, left-side/right-side boom lights, cab lights

- Programmable time-delay LED working lights

-

- Engine

-

- Cat C3.6 single turbo diesel engine

- One-touch low idle with auto engine speed control

- Auto engine shutdown

- 52°C (125°F) high-ambient cooling capacity without de-rate

- -25°C (-13°F) cold start capability

- Electric fuel priming pump

- Variable speed fan

- Single fuel filtration system

- Double element air filter with integrated precleaner

-

- Hydraulic System

-

- Boom and stick regeneration circuit

- Auto hydraulic warm up

- Auto two speed travel

- Electric main control valve

- Boom and stick drift reduction valve

- Electric boom snubber

- Auxiliary line support

-

- Safety And Security

-

- Rear and right-side-view cameras

- Ground-level engine shutoff switch

- Service platform with anti-skid plate and countersunk bolts

- Signaling/warning horn

-

- Service And Maintenance

-

- Grouped engine oil and fuel filters

- Ground-level engine oil dipstick

- Sampling ports for Scheduled Oil Sampling (S·O·S)

- Integrated vehicle health management system

-

- Undercarriage And Structures

-

- Grease lubricated track link

- Tie down points on base frame

- 3830 kg (8,440 lb) counterweight

Optional Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Boom And Sticks

-

- 4.65 m (15'3") Reach boom

- 2.4 m (7'8") stub + 2.44 (8'0") fore Variable Angle boom

- 4.27 m (14'4") Power Offset boom

- 2.2 m (7'3") Reach stick

- 2.5 m (8'2") Reach stick

- 2.8 m (9'2") Reach stick

- 2.8 m (9'2") Thumb Ready stick

- 3.0 m (9'10") Reach stick

-

- Cab

-

- Deluxe cab: air suspension heated seat, 254 mm (10") touchscreen monitor

- Premium cab: air suspension heated and cooled seat, 10" touchscreen monitor

- Cat Stick Steer

- Auxiliary relay

-

- Cat Technologies

-

- Cat Grade 2D with Attachment Ready Option (ARO)

- Cat Grade with 3D single GNSS

- VisionLink Productivity

- Cat Grade with 3D dual GNSS

-

- Electrical System

-

- 360° lighting

-

- Hydraulic System

-

- Boom and stick lowering check valves

-

- Safety And Security

-

- Cat Detect - People Detection

- Cat Command remote control

- 360° visibility

- Swing alarm

- Inspection lighting

-

- Undercarriage And Structures

-

- 500 mm (20 in) triple grouser shoes

- 500 mm (20") rubber track shoes

- 500 mm (20 in) triple grouser shoes with rubber pad

- 600 mm (24 in) triple grouser shoes

- 600 mm (24") rubber track shoes

- 700 mm (28 in) triple grouser shoes

- 770 mm (30 in) triple grouser shoes

- 2500 mm (8'2") blade

- 2600 mm (8'6") blade

- 2700 mm (8'10") blade

352 LRE Long Reach Excavation Hydraulic Excavator

352 LRE Long Reach Excavation Hydraulic Excavator  352 UHD Ultra High Demolition Hydraulic Excavator

352 UHD Ultra High Demolition Hydraulic Excavator  340 UHD Ultra High Demolition Hydraulic Excavator

340 UHD Ultra High Demolition Hydraulic Excavator  M322F Wheeled Excavator

M322F Wheeled Excavator  M317F Wheeled Excavator

M317F Wheeled Excavator  M320 Wheeled Excavator

M320 Wheeled Excavator  M322

M322  M319 Wheeled Excavator

M319 Wheeled Excavator  M316 Wheeled Excavator

M316 Wheeled Excavator  M318 Wheeled Excavator

M318 Wheeled Excavator  M315 Wheeled Excavator

M315 Wheeled Excavator  M314 Wheeled Excavator

M314 Wheeled Excavator