E361 – High Engine Coolant Temperature

The Electronic Control Module (ECM) detects a fault with the coolant temperature for the engine. The ECM detects the following faults:

The engine has been running for more than 185 seconds.

The trip point for the event code for the temperature of the engine coolant is reached.

Possible Performance Effects

E361-1 – None

E361-2 – The ECM will derate the power. The power will be derated at one percent per second.

E361-3 – The ECM will derate the power. The power will be derated at one percent per second.

Understanding the Importance of Cooling System Performance

Cooling system performance is a critical part of proper machine operation and engine service life.

Understanding how your cooling system works and ensuring its correct maintenance can help reduce the owning and operating costs of your equipment.

Diesel engine manufacturers have increased engine operating temperatures to improve engine efficiency. This increase in temperature means proper cooling system maintenance is especially important. The cooling system must remove heat to keep the engine at the correct operating temperature.

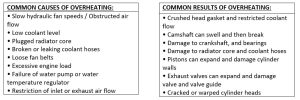

Engine overheating is something never to be ignored. Keep an eye on your temperature gauges, and never push your engine beyond its recommended load. If you see that your engine is running hot, the best thing to do is shut down the engine immediately. DO NOT EVER REMOVE THE RADIATOR CAP WHILE THE SYSTEM IS HOT- THIS CAN LEAD TO SEVERE PERSONAL INJURY!

High coolant temperatures can lead to poor engine performance and premature component wear – resulting in engine damage or failure. High engine temperatures can quickly increase your engine oil temperatures and lead to poor lubrication. As the oil temperature rises, its viscosity decreases, making it thinner. If your engine oil gets too thin, it will not be able to lubricate your engine properly, which can lead to accelerated wear.

Overheating severely shortens the engine service life. Find the cause of any problem in the cooling system and correct the problem immediately.

REMEMBER TO CHECK YOUR COOLING SYSTEM DAILY!

Inspect the coolant level in the top tank or the overflow tank.

Remove foreign material and dirt from outside the radiator core (and between the panels of folded core radiators).

Proper cooling system operation is vital to successful engine service life.

Always be aware of your machine condition,

Regular maintenance can help reduce your owning and operating costs.

Click here to download the Know your cooling System PDF

DON’T LET OVERHEATING COOK YOUR PROFITS!

WE OFFER EQUIPMENT MONITORING SERVICES

Find out how Equipment Monitoring Services can decrease your down time, and reduce your Operating Costs on our EM Services page.

Contact us to request services!

FIND YOUR REPRESENTATIVE

Have questions? Your PSSR can help – Find a representative today!