FUEL PRESSURE – AND WHY IT’S IMPORTANT

Most Common Fuel Pressure Fault Codes

EID 396 – High Fuel Rail Pressure

The fuel rail pressure is above an acceptable level. The code is logged. Engine power is derated. The engine may stop.

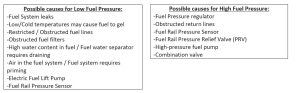

Possible causes for high fuel pressure include:

Fuel pressure regulator

Obstructed return lines

Fuel rail pressure sensor

Fuel Rail Relief Valve (PRV)

High-pressure fuel pump

Combination valve

EID 398 – Low Fuel Rail Pressure

The fuel rail pressure is below an acceptable level. The code is logged. Engine power is derated. The engine may stop.

Possible causes for a low fuel pressure include:

Fuel system leaks

Low/Cold temperatures may cause fuel to gel

Restricted/Obstructed fuel lines

Obstructed fuel filters

High water content in the fuel or the water separator requires draining

Air in the fuel system or fuel system requires priming

Electric fuel lift pump

Fuel rail pressure sensor

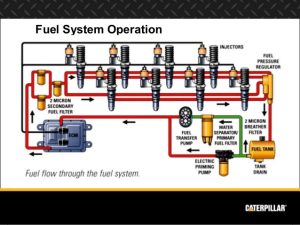

Caterpillar diesel engine fuel systems are composed of a specialized set of components that must deliver the correct amount of fuel to the cylinder – at the precise moment, it is needed.

A well-designed fuel system enables the engine to produce maximum power at maximum efficiency, with a minimum of exhaust emissions.

Components of a Basic Fuel System

The basic fuel system consists of a fuel transfer pump, fuel filters, fuel injectors, and a fuel pressure regulator. Fuel pressure is controlled by the pressure regulating valve, and it must be able to provide the correct fuel pressure to the injectors at all times.

Today’s diesel injectors must develop very high injection pressures to function with modern high-compression ratio engine designs. The fuel system is responsible for providing an adequate supply of clean and stable fuel for proper operation.

Results of Incorrect Fuel Pressure

Incorrect fuel pressure may result in conditions such as:

Engine derates

Poor acceleration

Engine hesitation

Poor throttle response

No start events

Inhibited Aftertreatment system operation

A variety of other performance concerns.

If you are experiencing performance concerns or have any questions about your equipment – Reach out to your service representative or your local H.O. Penn branch immediately.

Be sure to inspect and service your fuel system regularly. A healthy fuel system can increase the life span of your equipment and will ensure you always PRODUCE MAXIMUM POWER AT MAXIMUM EFFICIENCY.

WE OFFER EQUIPMENT MONITORING SERVICES

Find out how Equipment Monitoring Services can decrease your down time, and reduce your Operating Costs on our EM Services page.

Contact us to request services!

FIND YOUR REPRESENTATIVE

Have questions? Your PSSR can help – Find a representative today!