E – 284 – Low Brake Accumulator Pressure

Immediately perform a safe shutdown to prevent injury or severe damage.

The Service Brake Accumulator pressure is below the threshold for model specification.

When any brake accumulator pressure sensor diagnostic is active, the operator will experience a loss of service brake pressure. A level 3 warning will be active.

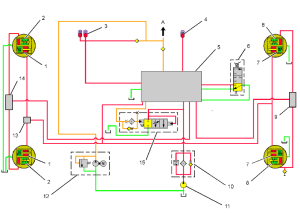

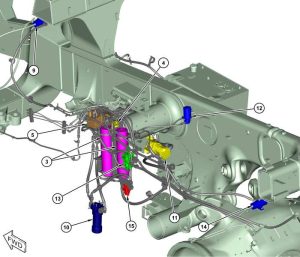

The brake charging pump supplies the parking brake accumulator and the service brake accumulator. The accumulators supply the required oil flow to ENGAGE the front and rear service brakes, and the accumulator supplies oil to DISENGAGE the rear parking brakes.

The pressure in the accumulators is monitored by a sensor in the accumulator charging valve and is electro-hydraulically controlled.

Low brake accumulator pressure can be caused by various concerns, and it is recommended that you Immediately Perform A Safe Shutdown To Prevent Injury Or Severe Damage when a fault occurs.

Diagnosing Low Brake Accumulator Pressure

Initial diagnosis should begin with the following:

- Visually inspecting and testing the brake system and associated components.

- Verify and test all brake system and accumulator pressures

- Inspecting the brake system for proper adjustment, leaks, restrictions, obstructions, and contaminants.

- Verify and update software to the latest available version – Maintaining the latest software in all ECMs will allow the machine to operate at peak performance.

Low brake accumulator pressures can lead to brake/parking system operational concerns, premature component wear, or brake/parking system failure.

Brake system faults should be addressed immediately as they may be a

SAFETY CONCERN FOR THE OPERATOR, WORK SITE, OR MACHINE.

Please contact your H.O Penn service representative with any questions or to schedule a service visit.

We Offer Equipment Monitoring Services

Find out how Equipment Monitoring Services can decrease your downtime and reduce your Operating Costs on our EM Services page.

Contact us to request services!

Request ServiceFind Your Representative

Have questions? Your PSSR can help – Find a representative today!