Low Transmission Oil Pressure

IMMEDIATE SAFE SHUTDOWN IS REQUIRED. Activated when the transmission oil pressure is below acceptable model parameters. Check Transmission and associated lines for problems such as leakage. Check Transmission Main Relief Valve Pressure.

Caterpillar products use several types of transmissions, and each is designed to convert engine power into the exact combination of speed, direction and torque required for the particular application.

The transmission is a critical part of a machine’s power train, and incorrect oil pressure is one of the primary causes of premature transmission failure or reduced power output/performance. The unit is designed to operate at the designated pressure and low pressures may result in operational concerns, slippage, jerky shifting, overheating, premature component wear, or transmission failure.

Determine if a Low Transmission Oil Pressure Indicates a Hardware Concern

Complete the following troubleshooting steps to help determine if a LOW TRANSMISSION OIL PRESSURE event code is indicating a hardware concern:

- Check the transmission oil level. The oil level indicator is sensitive, so ensure that the following conditions are met:

- Machine needs to be on flat ground

- Transmission oil temperature needs to be a minimum of 80° C (176° F)

- Run the engine at low idle

- Inspect system for leaks, restrictions, obstructions, and contaminants

- Submit an SOS Oil Sample for fluid analysis

- Check the transmission main relief pressure.

- Check the transmission clutch pressures.

- Service transmission filters and cut open old filters to inspect for debris/contaminants

- If a transmission hardware issue is suspected, check the transmission suction screen. Work with your H.O Penn representative to determine the correct action of repairs.

Check your transmission filter and oil levels in the transmission often. They may need to be serviced or replaced. Contamination from failing parts can cause plugged filters and additional component wear.

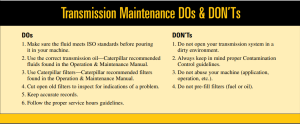

Caterpillar Transmission Maintenance Dos & Don’ts

Dos:

- Make sure the fluid meets ISO standards before pouring it into your machine.

- Use the correct transmission oil. Caterpillar recommended fluids are found in the Operation & Maintenance Manual.

- Use Caterpillar filters. Caterpillar recommended filters are found in the Operation & Maintenance Manual.

- Cut open old filters to inspect for indications of a problem.

- Keep accurate records.

- Follow the proper service hour guidelines.

Don’ts:

- Do not open your transmission system in a dirty environment.

- Always keep in mind proper Contamination Control guidelines.

- Do not abuse your machine (application, operation, etc.).

- Do not pre-fill filters (fuel or oil).

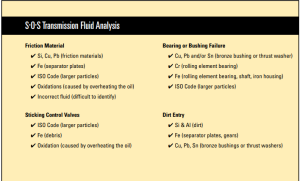

SOS Transmission Fluid Analysis

The transmission oil should be properly sampled and submitted to the SOS Fluid Lab for analysis.

Our fluid analysis experts do the rest—using proprietary processes, sophisticated chemistry and the latest technology to reveal excessive wear, contaminated fluids or other “unseen” issues. You’ll receive a report with information you understand, along with recommendations you can act on quickly.

Fluid analysis is available for any and all of your equipment’s fluids, and can assist in identifying and preventing compartmental failures.

Maximize the Life of Your Transmission

Regular preventive maintenance is vital for any machine to be safe, reliable and productive. It is the most cost-effective way to keep your transmission operating at peak performance. If you take care of your transmission, the gears and shafts can last through multiple rebuilds- increasing the overall transmission life. You can take a proactive approach by planning for scheduled downtime, maintenance and repair costs.

Following a planned maintenance program and Caterpillar’s recommended maintenance guidelines can help ensure longer life for your transmission and reduce machine downtime.

For further information please contact you H.O. Penn Representative and EM services team!

Please contact your H.O Penn service representative with any questions or to schedule a service visit

We Offer Equipment Monitoring Services

Find out how Equipment Monitoring Services can decrease your down time, and reduce your Operating Costs on our EM Services page.

Contact us to request services!

Request ServiceFind Your Representative

Have questions? Your PSSR can help – Find a representative today!