CB16 Tandem Vibratory Roller

Compactors

Landfill Compactors (4)

Pneumatic Rollers (3)

Soil Compactors (2)

Tandem Vibratory Rollers (35)

-

CD44B Drum Steer Tandem Vibratory Roller (Split Drum)

-

CD54B Drum Steer Tandem Vibratory Roller (Solid Drum)

-

CD54B Drum Steer Tandem Vibratory Roller (Split Drum)

-

CD44B Drum Steer Tandem Vibratory Roller (Solid Drum)

-

CB64 Vibratory Asphalt Compactors

-

CB54B Tandem Vibratory Roller (Split Drum)

-

CB66B Tandem Roller

-

CB54 XW Tandem Vibratory Roller

-

CB54B Tandem Vibratory Roller (Solid Drum)

-

CB7 Tandem Roller

-

CB10 Tandem Vibratory Roller

-

CD8 – Solid Drum

-

CD8 – Split Drum

-

CCS7 Smooth Drum Vibratory Combination Compactor

-

CD10 Solid Drum Vibratory Roller

-

CB10 Split Drum Vibratory Roller

-

CC24B Utility Compactor

-

CB24B

-

CCS9 Smooth Drum Combination Vibratory Compactor

-

CB16 Tandem Vibratory Roller

-

CB13 Tandem Vibratory Roller

-

CB15 Tandem Vibratory Roller

-

CB10 Tandem Vibratory Roller

-

CB7 Tandem Roller

-

CB4.4 Utility Compactor

-

CB4.0 Utility Compactor

-

CB4.4 Utility Compactor

-

CB2.9 Utility Compactor

-

CB2.7 Utility Compactor

-

CC2.7 Utility Compactor

-

CB2.7 GC Utility Compactor

-

CB2.5 GC Utility Compactor

-

CB2.5 Utility Compactor

-

CB1.8 Utility Compactor

-

CB1.7 Utility Compactor

Vibratory Soil Compactors (21)

-

CS54B Vibratory Soil Compactor

-

CS56B Vibratory Soil Compactor

-

CP56B Vibratory Soil Compactor

-

CP54B Vibratory Soil Compactor

-

CP12 GC Vibratory Soil Compactor

-

CS12 GC Vibratory Soil Compactor

-

CP34 Vibratory Soil Compactor

-

CS44B Vibratory Soil Compactor

-

CP44B Vibratory Soil Compactor

-

CS34 Vibratory Soil Compactor

-

CS14 Vibratory Soil Compactor

-

CS16 Vibratory Soil Compactor

-

CS19 Vibratory Soil Compactor

-

CP11 GC Vibratory Soil Compactor

-

CS11 Vibratory Soil Compactor

-

CS12 Vibratory Soil Compactor

-

CS13 GC Vibratory Soil Compactor

-

CS11 GC Vibratory Soil Compactor

-

CS10 GC Vibratory Soil Compactor

-

CS7 Vibratory Soil Compactor

-

CS5 Vibratory Soil Compactor

Overview

The CB16 asphalt compactor offers enhancements that simplify operation, provide versatility, and deliver excellent fuel economy. Rotary dials, oscillatory vibration, and 360 degreeseating make this compactor a perfect match for urban streets, rural roads, highways, interstates and other high-production applications.

- Simple to Operate, Easy to Learn

- Better Fuel Economy

- Easy Vibratory System Set-up

- Compaction Options Include Oscillation

- Ensure Mat Coverage with Compaction Control

- Prevent Build-Up, Keep the Drum Surfaces Wet

- Boost Performance with Enhanced Visibility

- Product Link™

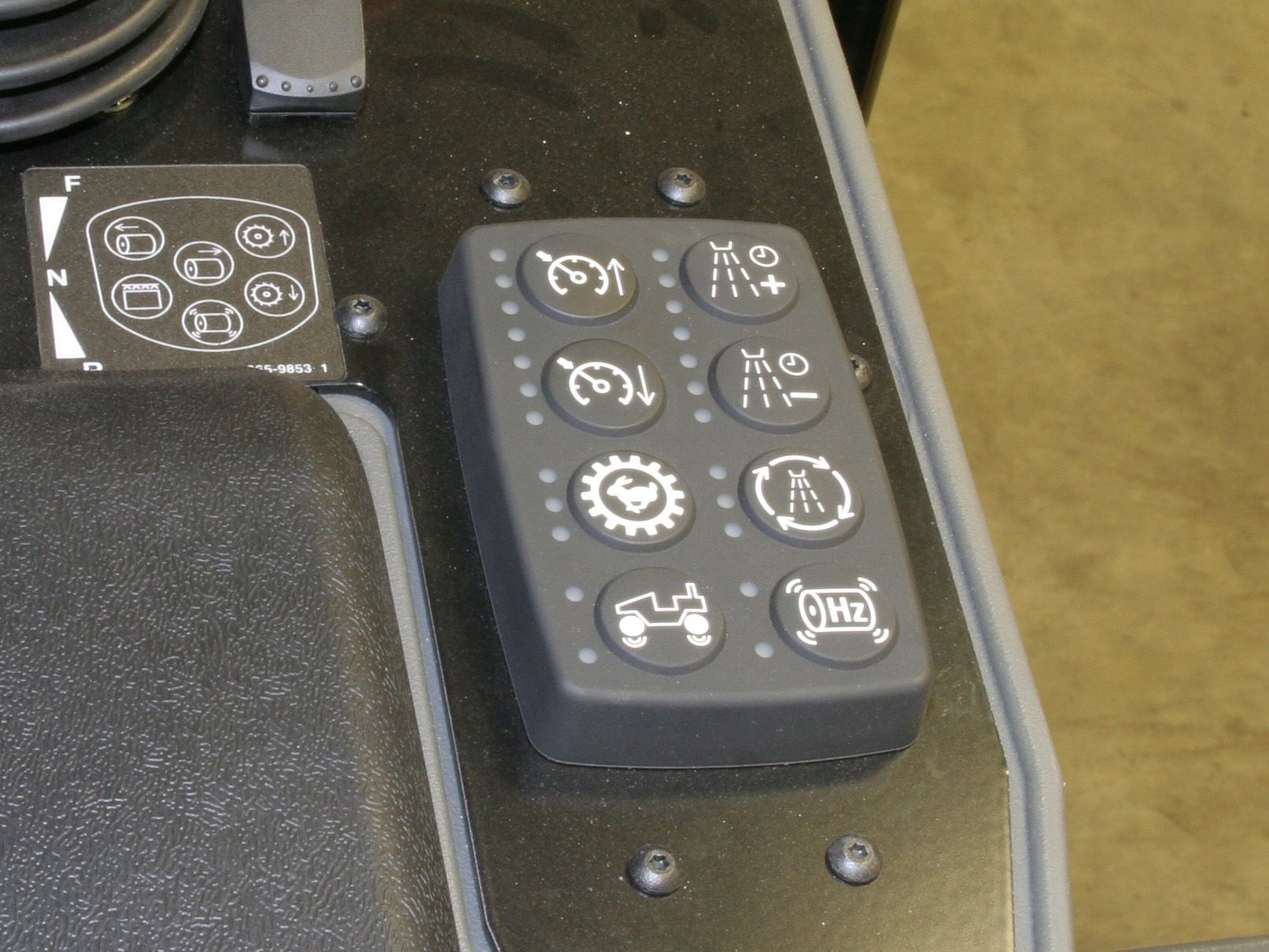

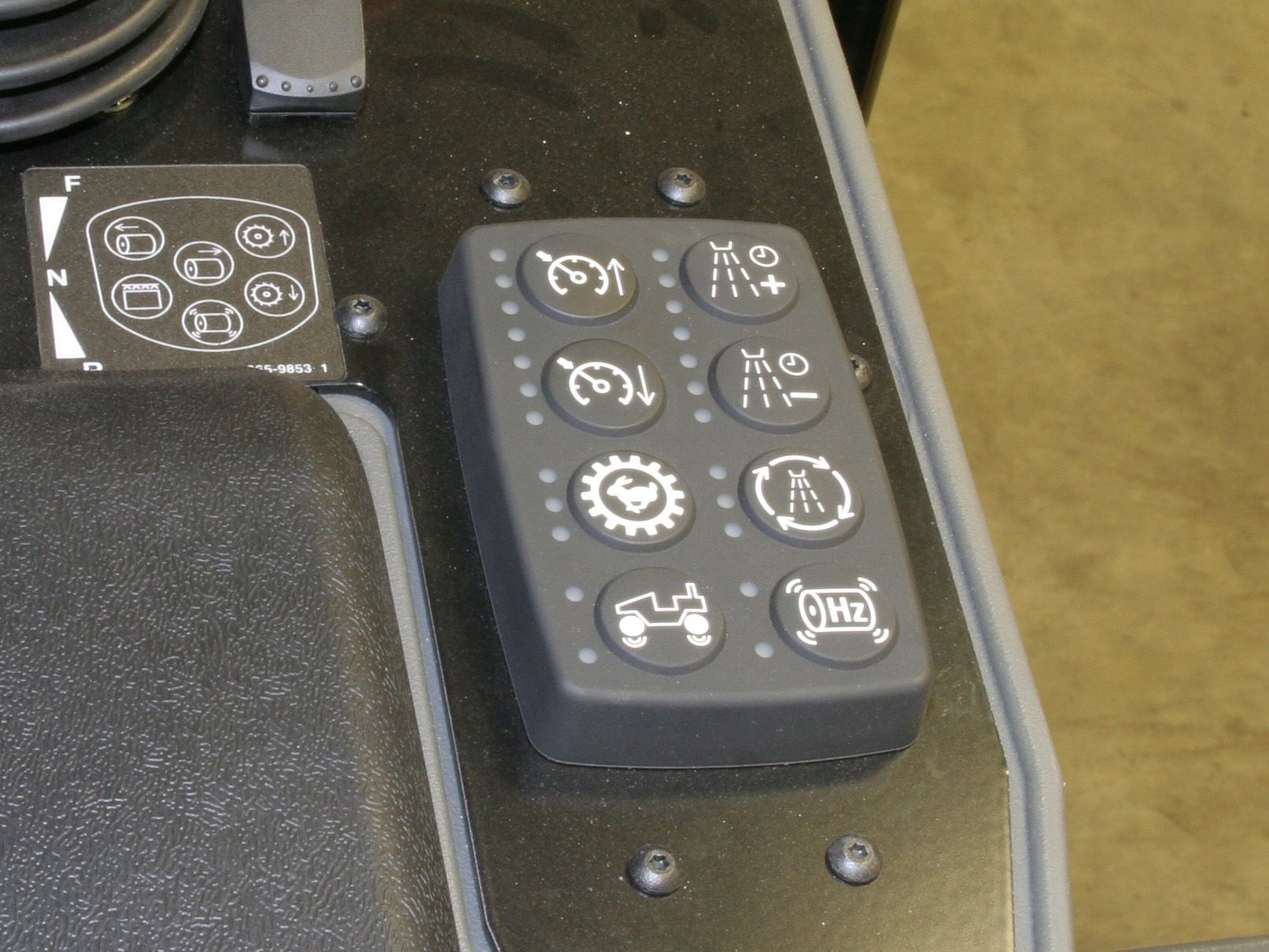

Simple to Operate, Easy to Learn

- Innovative hand-wheel steering technology delivers precise control and good forward visibility

- Easily activate the vibratory system, water spray system, and drum offset with the multi-function propel handle

- Machine functions with LED indicators have been independently grouped for simplified control and quick activation

Better Fuel Economy

- Get up to 10% better fuel economy with the Cat C4.4 engine and standard Eco-mode

- The C4.4 engine provides 106 kW (142 hp) of power and meets regional emissions requirements

- Unique Eco-mode design modifies engine speed based on load requirements; high amplitude vibration utilizes higher engine speed, while static rolling conserves fuel and operates at low engine speed with even lower sound levels

Easy Vibratory System Set-up

- Five amplitude system utilizes a single frequency with five distinct amplitudes that provide excellent performance on thick lifts and rigid mix designs

- Versa Vibe™ vibratory system creates a 2-in-1 machine with four amplitudes and two frequencies; two settings for lighter hitting and higher working speeds on thin lifts; and two settings for heavier hitting and slower speeds on thick lifts and challenging mix designs

Compaction Options Include Oscillation

- Oscillatory vibration on the rear drum combined with standard vertical vibration front drum delivers both performance and versatility

- Oscillation system utilizes proven pod-style eccentric weight technology developed by Caterpillar

- 2 year/2000 hour service interval helps maximize uptime and limit maintenance costs.

Ensure Mat Coverage with Compaction Control

- Pass-count and Temperature Mapping combines infrared temperature sensors with GPS mapping to keep the operator informed of current asphalt temperatures, machine position, pass-count, and layer coverage

- Compaction Meter Value (CMV) utilizes a drum-mounted accelerometer to measure the combined stiffness of the asphalt layer, base layer, and sub-base layer to indicate road structure quality beneath the surface

Prevent Build-Up, Keep the Drum Surfaces Wet

- High capacity water tank provides long duration between fills

- Dual water pumps provide back-up capability and alternate with direction of travel to maximize service life

- Triple filtration prevents clogs with filters located at the fill point, water pumps, and spray nozzles

- Integrated freeze protection kit (optional) provides protection in cold temperatures when machine is not in use

Boost Performance with Enhanced Visibility

- Optimize sight lines with 360 seating option; always face the direction of travel

- LED Lighting delivers excellent job site illumination while conserving energy

- Night-lighting option provides additional illumination to the ROPS/Cab, drum edges, and drum surfaces

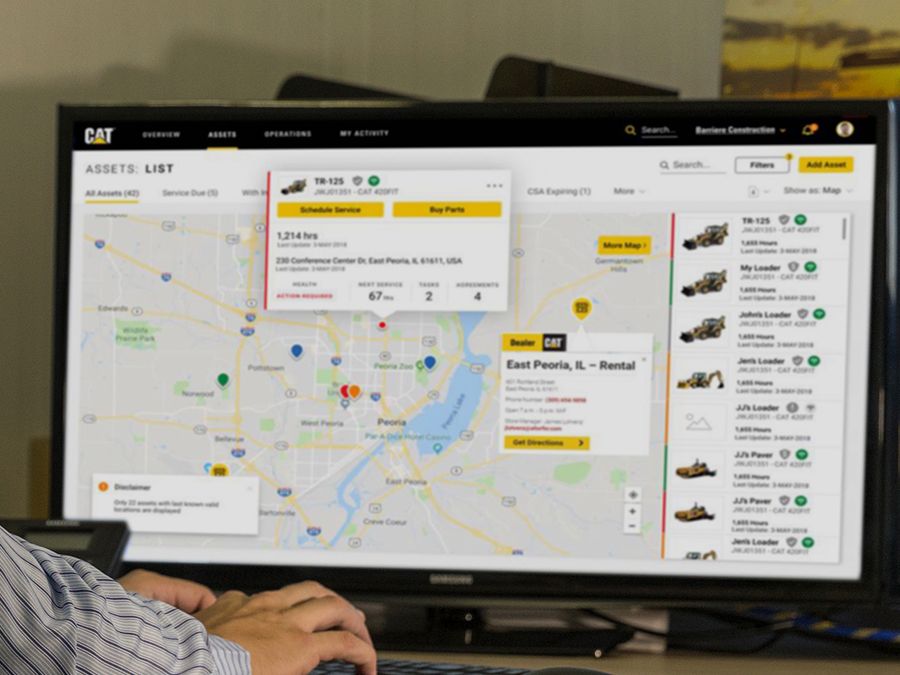

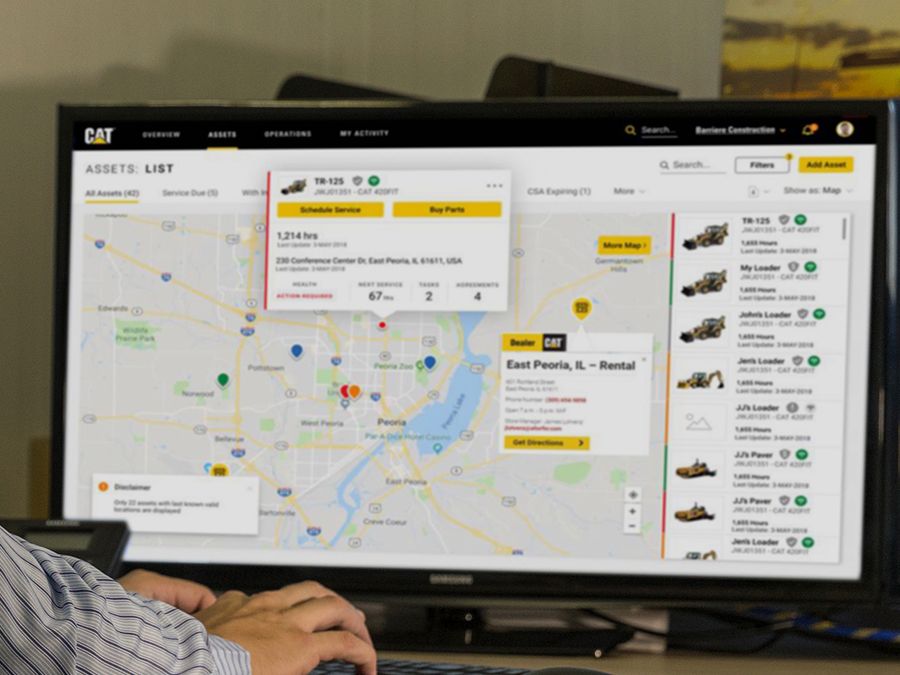

Product Link™

- Make timely, fact-based decisions to maximize efficiency, improveproductivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time

- Diagnostic codes are made available through online web applications

- Remote flash works around your schedule to ensure your machine’s software is up to date for optimal performance

Simple to Operate, Easy to Learn

- Innovative hand-wheel steering technology delivers precise control and good forward visibility

- Easily activate the vibratory system, water spray system, and drum offset with the multi-function propel handle

- Machine functions with LED indicators have been independently grouped for simplified control and quick activation

- Dual side access on ROPS/Canopy machines provide operators with flexibility to mount and dismount the machine (U.S. and Canada only)

Better Fuel Economy

- Get up to 10% better fuel economy with the Cat C4.4 engine and standard Eco-mode

- The C4.4 engine provides 106 kW (142 hp) of power and meets regional emissions requirements

- Unique Eco-mode design modifies engine speed based on load requirements; high amplitude vibration utilizes higher engine speed, while static rolling conserves fuel and operates at low engine speed with even lower sound levels

Easy Vibratory System Set-up

- Five amplitude system utilizes a single frequency with five distinct amplitudes that provide excellent performance on thick lifts and rigid mix designs

- Versa Vibe™ vibratory system creates a 2-in-1 machine with four amplitudes and two frequencies; two settings for lighter hitting and higher working speeds on thin lifts; and two settings for heavier hitting and slower speeds on thick lifts and challenging mix designs

- 2-amplitude/2-frequency vibratory system automatically optimizes amplitude and frequency with a single switch for simple thin/thick lift operation

- Reach compaction goals with automatic speed control; green indicators help ensure travel speed matches correct impact spacing

Compaction Options Include Oscillation

- Oscillatory vibration on the rear drum combined with standard vertical vibration front drum delivers both performance and versatility

- Oscillation system utilizes proven pod-style eccentric weight technology developed by Caterpillar

- 2 year/2000 hour service interval helps maximize uptime and limit maintenance costs.

- Durable power-transmission belt delivers 2-times the load capacity of timing belt systems leading to extended life

- Standard drum shells offer exceptional long-term life on a variety of mix designs and delivers outstanding mat texture, density, and smoothness.

Ensure Mat Coverage with Compaction Control

- Pass-count and Temperature Mapping combines infrared temperature sensors with GPS mapping to keep the operator informed of current asphalt temperatures, machine position, pass-count, and layer coverage

- Compaction Meter Value (CMV) utilizes a drum-mounted accelerometer to measure the combined stiffness of the asphalt layer, base layer, and sub-base layer to indicate road structure quality beneath the surface

- Machine to Machine communication helps keep rolling patterns in sync by sharing mapped data such as CMV, temperature mapping, and pass count coverage between multiple machines

Prevent Build-Up, Keep the Drum Surfaces Wet

- High capacity water tank provides long duration between fills

- Dual water pumps provide back-up capability and alternate with direction of travel to maximize service life

- Triple filtration prevents clogs with filters located at the fill point, water pumps, and spray nozzles

- Integrated freeze protection kit (optional) provides protection in cold temperatures when machine is not in use

Boost Performance with Enhanced Visibility

- Optimize sight lines with 360 seating option; always face the direction of travel

- LED Lighting delivers excellent job site illumination while conserving energy

- Night-lighting option provides additional illumination to the ROPS/Cab, drum edges, and drum surfaces

Product Link™

- Make timely, fact-based decisions to maximize efficiency, improveproductivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time

- Diagnostic codes are made available through online web applications

- Remote flash works around your schedule to ensure your machine’s software is up to date for optimal performance

Vibratory System

- Minimum Frequency

- 2520VPM

- Centrifugal Force per Drum - Maximum

- 31069lb

- Maximum Frequency

- 3800VPM

- Centrifugal Force per Drum - Minimum

- 12409lb

- Minimum Amplitude

- 0.01in

- Maximum Amplitude

- 0.041in

- Vibration Selection

- Independent per drum, front only, rear only, both

Service Refill Capacities

- Water Spray Tank Capacity

- 264gal (US)

- Fuel Tank Capacity

- 66gal (US)

Dimensions

- Overall Width

- 92in

- Height - With ROPS/FOPS

- 10ft

- Wheel Base

- 11.25ft

- Overall Length

- 15.5ft

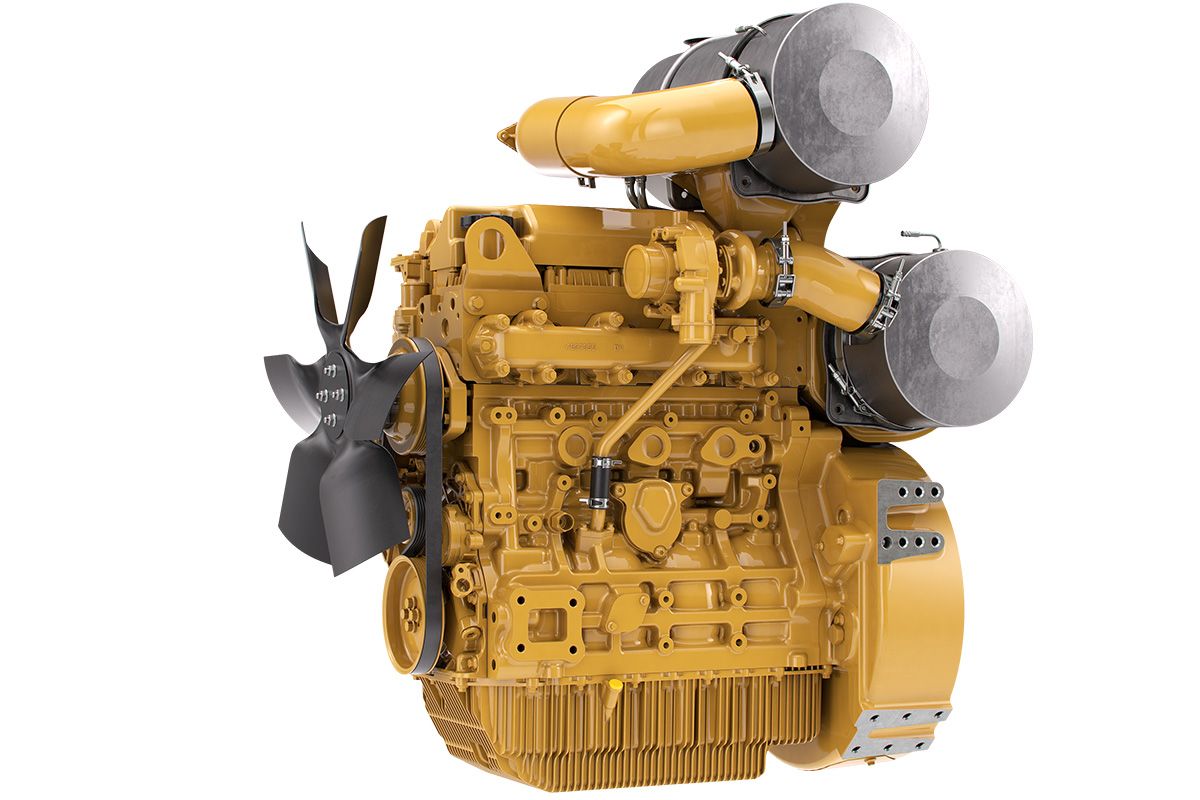

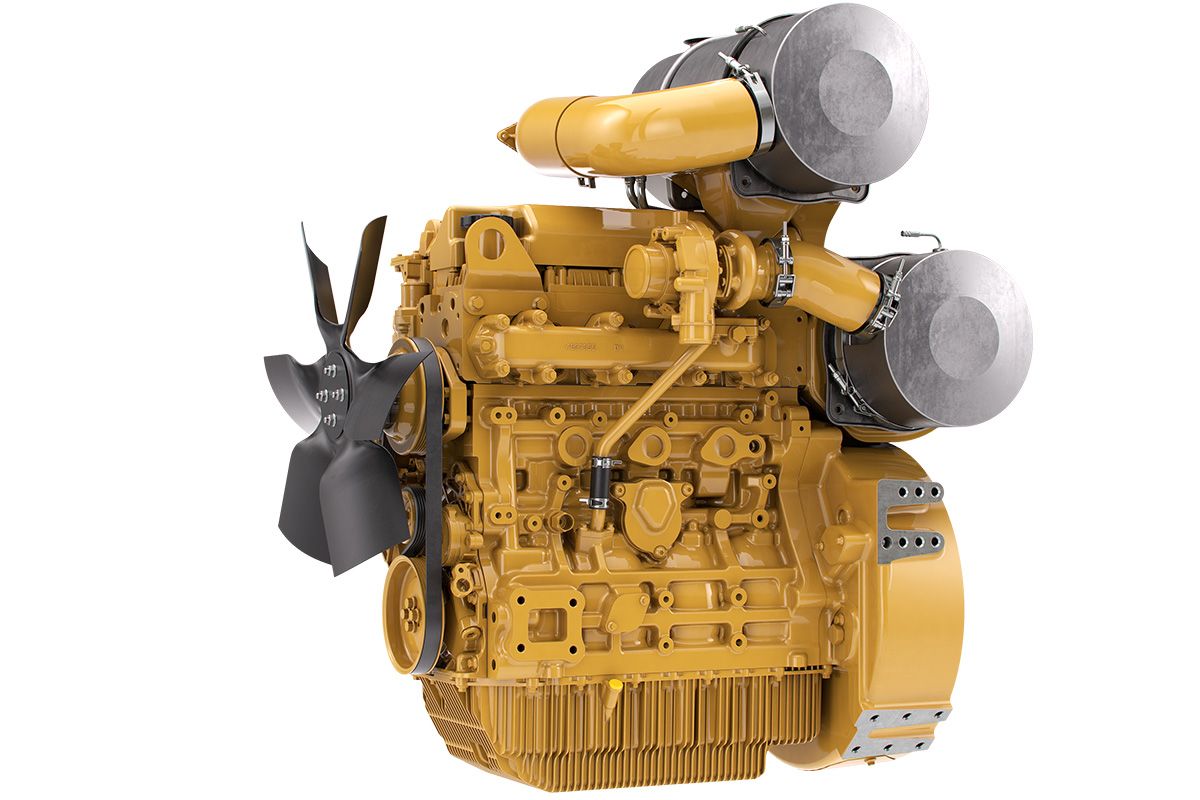

Engine

- Engine Model

- Cat C4.4

- Gross Power

- 142HP

Travel Speeds

- Low

- 4.5mile/h

- High

- 8mile/h

Operating Specifications

- Maximum Compaction Width

- 90in

- Drum Offset

- 6in

- Ground Clearance

- 11.5in

- Curb Clearance

- 28in

- Standard Compaction Width

- 84in

Weights

- Maximum Operating Weight

- 34255lb

- Static Linear Load

- 204lb/in

- Standard - Operating Weight

- 31941lb

Standard/Optional Features

Standard Equipment:

-

- Operating Environment

-

- 180 degree seat positioning with sliding station

- Adjustable armrests

- Platform ROPS/FOPS

- Propel lever with 4-button control

- Steering wheel - fixed position, left side

- Suspension seat - no heat

- 76 mm (3 in) high visibility seatbelt

- Vandalism protection

-

- Technology

-

- Product Link™ PLE743

- Remote Flash

- Remote Troubleshooting

-

- Powertrain

-

- Cat C4.4, 4-cylinder

-

- Electrical System

-

- 150 amp alternator

- 12-volt charging system

- Automotive-type fuse system

- Maintenance-free batteries

- Cat Electronic Technician (Cat ET)

- Remote start/charge receptacle

-

- Service And Maintenance

-

- Maintenance-free Hitch

- 3 yr/3000 hr conventional vibratory system service interval

- 2 yr/2000 hr oscillatory vibration system service interval

- Grouped filters with ground level access

- Remote access drains

- Sampling ports for Scheduled Oil Sampling

- Site gauges

-

- Safety

-

- Backup Alarm

- Warning horn (front & rear)

- LED Working Lights

- Steps, front drum fuel refill

- Warning, LED safety beacons

Optional Equipment:

-

- Operating Environment

-

- 360 degree seat positioning with sliding station

- Steering wheel - elevated position, left side

- Suspension seat w/ heat

- Seat headrest

-

- Technology

-

- Infrared asphalt temperature sensors

- CMV accelerometer - front drum

- GNSS Mapping - temperature and passcount

- Machine to machine communication

- Product Link PLE783

-

- Powertrain

-

- Offset hitch

-

- Vibratory System

-

- Biodegradeable hydraulic oil

- Five amplitude vibratory system

- Two amplitude/two frequency vibratory system

- Versa Vibe™ vibratory system

- Two amplitude/two frequency w/Oscillation vibratory system

- Versa Vibe w/Oscillation vibratory system

- Cocoa mats

- Mats - water distribution

- Freeze protection - water spray system

- Rear drum oscillation kit - field installed drum

-

- Safety

-

- LED Working Lights with turn signals

- LED Roading Lights

- Mirror package

- Steps, rear drum water spray refill

836K Landfill Compactor

836K Landfill Compactor  826K Landfill Compactor

826K Landfill Compactor  816 Landfill Compactor

816 Landfill Compactor  826 Landfill Compactor

826 Landfill Compactor  CW34 Pneumatic Roller

CW34 Pneumatic Roller  CW16 Pneumatic Roller

CW16 Pneumatic Roller  825K Soil Compactor

825K Soil Compactor  815 Soil Compactor

815 Soil Compactor