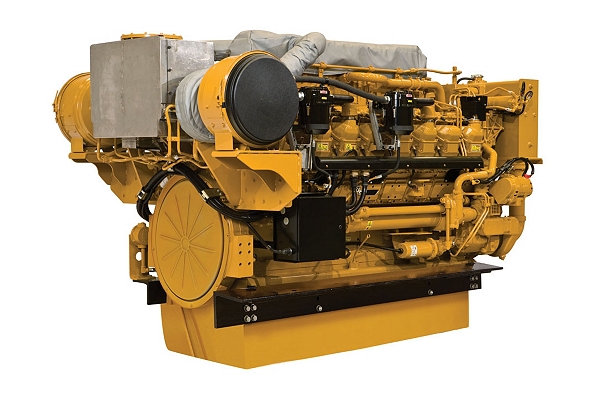

3516C Propulsion Engine (Tier 3)

Commercial Propulsion Engines

Commercial Propulsion Engines (21)

-

C280-12 Marine Propulsion Engine (EPA Tier 4)

-

C280-16 Commercial Marine Propulsion Engine

-

C280-8 Marine Propulsion Engine (U.S. EPA Tier 4)

-

C280-12 Propulsion Engine

-

Cat C280-8 Propulsion Engine

-

3516E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3516C Propulsion Engine (Tier 3)

-

C280-6 Propulsion Engine

-

3512C Tier 3 Marine Propulsion Engine

-

3512E Marine Propulsion Engine (U.S. EPA Tier 4 Final)

-

3516C Marine Propulsion Engine

-

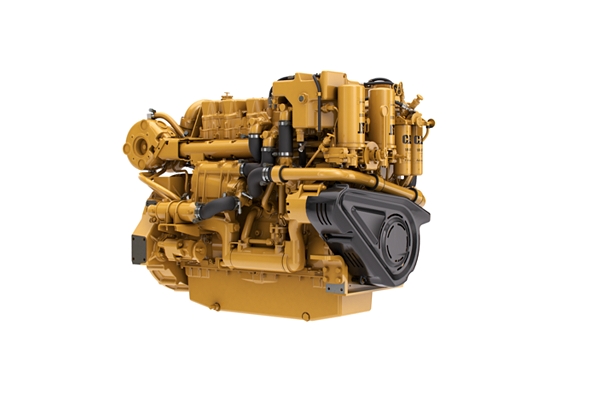

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

-

Cat C32 Propulsion Engine (US EPA Tier 4 / IMO III)

-

3508C Propulsion Engine

-

3512C Propulsion Engine (IMO II)

-

Cat C18 ACERT Propulsion Engine (Tier 3)

-

Cat C32 Propulsion Engine (IMO II)

-

Cat C32 ACERT Marine Propulsion Engine (EPA Tier 3)

-

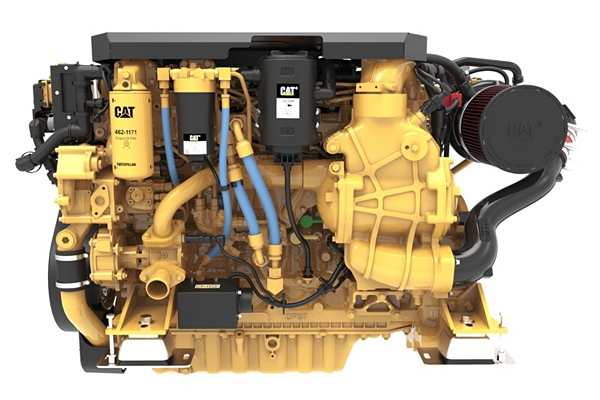

C7.1 Marine Propulsion Engine (U.S. EPA Tier 3 / IMO II)

-

C9.3 Commercial Propulsion Engine

-

Cat C18 ACERT Propulsion Engine (IMO II)

Overview

The 3516C propulsion engine is available with a wide range of ratings that meet EPA Tier 3 and IMO II regulations without any additional aftertreatment. These engines provide efficient operation with electronic governing, cold mode start strategy, and programmable low idle to minimize fuel consumption. The 3516C engine also incorporates a closed crankcase ventilation system to lower emissions.

- Complete Solutions for Your Marine Application

- Efficient Operation

- Improved Performance and Function

- Environmentally Conscious

Complete Solutions for Your Marine Application

• Single-source for support and service • Industry-leading warranty coverage for factory packaged components • Global dealer network for service in any location

Efficient Operation

• Instrument panel with cold mode start strategy and programmable low idle • Electronic governing control unit minimizes fuel consumption and monitors engine operating parameters • Optional alarm and protection system

Improved Performance and Function

• Advanced combustion design uses the optimum configurations and cylinder geometry • Enhanced control of fuel injection optimized through crank timing

Environmentally Conscious

• Closed crankcase ventilation system and redesigned piston for improved efficiency and lower emissions • Optimal nozzle geometry and electronic injection control for improved fuel delivery • EPA Marine Tier 3/IMO Tier II Emissions Compliant

Complete Solutions for Your Marine Application

• Single-source for support and service • Industry-leading warranty coverage for factory packaged components • Global dealer network for service in any location

Efficient Operation

• Instrument panel with cold mode start strategy and programmable low idle • Electronic governing control unit minimizes fuel consumption and monitors engine operating parameters • Optional alarm and protection system

Improved Performance and Function

• Advanced combustion design uses the optimum configurations and cylinder geometry • Enhanced control of fuel injection optimized through crank timing

Environmentally Conscious

• Closed crankcase ventilation system and redesigned piston for improved efficiency and lower emissions • Optimal nozzle geometry and electronic injection control for improved fuel delivery • EPA Marine Tier 3/IMO Tier II Emissions Compliant

Power Rating

- Power Range

- 2131-2675 bhp (1590-1995 bkW)

- Power Range

- 2131-2675 bhp (1590-1995 bkW)

Engine Specifications

- Speed Range

- 1600 rpm

- Emissions

- EPA Tier 3, IMO II

- Aspiration

- TTA

- Bore

- 6.69in

- Stroke

- 8.46in

- Displacement

- 4765.0in3

- Configuration

- Vee 16, 4-Stroke-Cycle Diesel

- Rotation from Flywheel End

- Counterclockwise

- Speed Range

- 1600 rpm

- Emissions

- EPA Tier 3, IMO II

- Aspiration

- TTA

- Bore

- 6.69in

- Stroke

- 8.46in

- Displacement

- 4765in³

Dimensions & Weights

- Dry Weight

- 21164.0lb

- Length

- 125.7in

- Width

- 89.9in

- Height

- 87.6in

- Dry Weight

- 21164lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Corrosion-resistant separate circuit aftercooler core, air cleaners with service indicator, dual turbochargers, closed crankcase ventilation system

-

- Control System

-

- Dual A4 engine control modules provide engine control and monitoring, rigid wiring harness with plug and run connectors on port and starboard sides

-

- Cooling System

-

- Separate circuit auxiliary fresh water pump, centrifugal non-self-priming auxiliary sea water pump, gear driven centrifugal jacket water pump, expansion tank, engine oil cooler, thermostats and housing

-

- Exhaust System

-

- Dry gas-tight exhaust manifolds with SOLAS compliant stainless steel heat shields, dual turbochargers with water-cooled bearings and heat shields, modular pulse exhaust manifold, single exhaust outlet

-

- Fuel System

-

- Electronically controlled unit injectors, fuel filter with service indicators, fuel transfer pump, SOLAS compliant fuel connections with spill shield

-

- Instrumentation

-

- Instrument panel shipped loose with Color Marine Power Display (MPD), alarm horn, overspeed shutdown notification light, emergency stop notification light, secondary ECU “Ready” light, secondary ECU “Active” light, graphic display unit for analog or digital display of oil and fuel pressure, oil and fuel filter differential, system DC voltage, exhaust and water temperature, air inlet restriction, service meter, engine speed, fuel consumption (total and instantaneous)

-

- Lube System

-

- Pre-lube strategy, top-mounted dual crankcase breathers, oil filter with service indicators, oil level gauge, oil filler, gear-type oil pump

-

- Power Take-offs

-

- Accessory drives — upper RH, upper and lower LH; two-sided front housing

-

- Protection System

-

- A4 electronic control module with customer programmable engine derate strategies, engine alarms and diagnostics displayed on local and remote MPDs, emergency stop pushbutton, safety shutoff protection for oil pressure and water temperature, overspeed protection

-

- General

-

- Vibration damper and guard, Cat® yellow paint, two lifting eyes attach to engine block,

-

- Iso Certification

-

- Factory-designed systems built at Caterpillar ISO 9001:2000 certified facilities

-

- Mounting System

-

- Mounting rails

Optional Equipment:

-

- Air Inlet System

-

- Air Cleaner Removal

- Remote Air Inlet Adapters

-

- Charging System

-

- Battery Charger

- Charging Alternator

-

- Control System

-

- Throttle Position Sensor

- Throttle Synchronization

-

- Cooling System

-

- Water Level Switch Gauge

- Coolant Level Sensors

- Connections

- Keel Cooling Conversions

- Heat Exchangers

- Auxiliary Water Pumps

- Sea Water Pump Removal

- Coolant Shunt Tanks

- Air Separator

- Marine Gear Cooling

-

- Exhaust System

-

- Exhaust Outlet

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

-

- Fuel System

-

- Fuel Cooler

- Fuel Priming Pumps

- Flexible Fuel Lines

- Rigid Fuel Lines

- Primary Fuel Filter

- Fuel level switch

-

- Instrumentation

-

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface

- Thermocouples

- Remote Panel Display

- Remote Cylinder Temperature Display

- Pilot House Instrument Panels

- Marine Gear Sensors

- Engine Vision Display System

-

- Lube System

-

- Oil Pan

- Oil Pan Accessories

- Sump Pumps

- Prelubrication Options

- Lubricating Oil

- Centrifugal Oil Filter

-

- Mounting System

-

- Engine Supports

- Vibration Isolation Mountings

-

- Power Take-offs

-

- Flexible Coupling and Guards

- Front Housing Accessories

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take Offs

- Crankshaft Pulleys

- Damper Guard Removals

-

- Protection System

-

- Air Inlet Shutoffs

- Switches and Contactors

- Explosion Relief Valve

- Sensors

-

- Spare Parts Kits

-

- Parts Kits

- Pump Kits

- Fuel Transfer

- Lube Oil

-

- Special Appearance

-

- Chrome Plated Relief Valves

- Black Air Cleaners

-

- Starting System

-

- Starting Motors or Barring Device

- Air Starting Motors Options

- Starting Aids

- Battery Sets - 24 Volt - Dry

- Battery Rack

-

- General

-

- Tool Set

- Caterpillar Datalink Wire