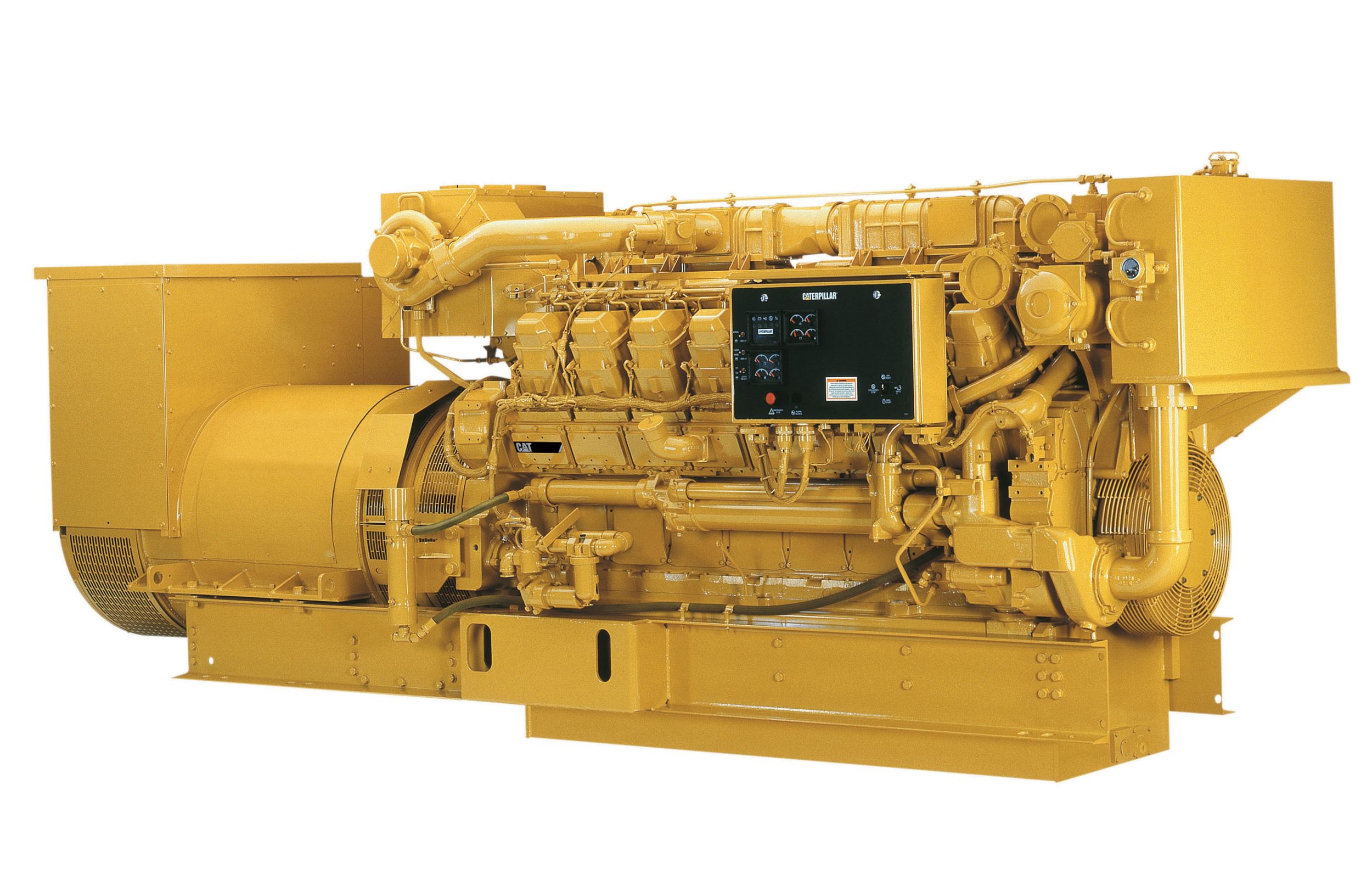

Cat 3516B Marine Auxiliary/Generator Set Engine

Auxiliary Engines

Auxiliary Engines (16)

-

Cat 3512B Marine Auxiliary/Generator Set Engine

-

Cat 3516B Marine Auxiliary/Generator Set Engine

-

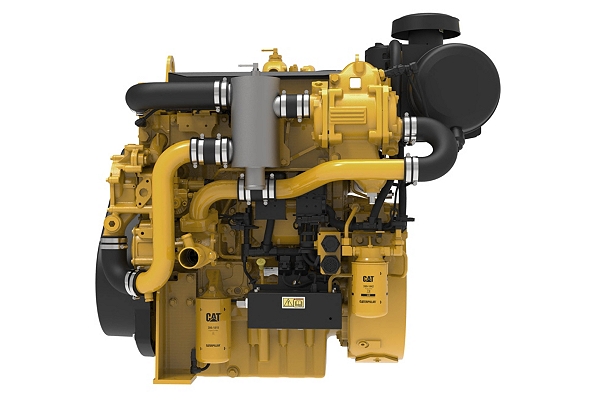

Cat C9 Marine Generator Set Engine

-

3516E Marine Auxiliary Engine (U.S. EPA Tier 4 Final)

-

Cat C280 Marine Auxiliary Engines

-

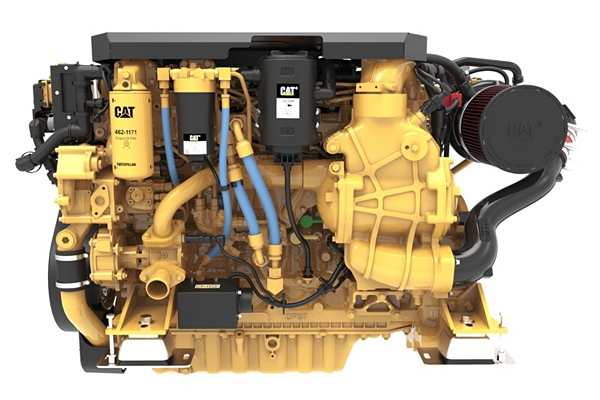

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (US EPA Tier 4 / IMO III)

-

3512E Marine Auxiliary/DEP Engine (U.S. EPA Tier 4 Final)

-

Cat C32 Auxiliary / Diesel Electric Propulsion Engine (IMO III)

-

Cat C32 Auxiliary/Generator Set Engine (IMO II)

-

Cat C32 Auxiliary/Generator Set Engine (EPA Tier 3)

-

Cat C32 Auxiliary / Diesel Electric Propulsion (US EPA Tier 3 / IMO II)

-

C9.3 Marine Auxiliary Engine

-

Cat C18 Auxiliary/Generator Set Engine (IMO II)

-

Cat C18 Auxiliary/Generator Set Engine (EPA Tier 3)

-

C4.4 (Electronic Control System)

-

C7.1 Marine Auxiliary Engine (U.S. EPA Tier 3 / IMO II)

Overview

The 3516B Auxiliary/Generator Set Engine incorporates a separate circuit aftercooling (SCAC) or sea water aftercooling (SWAC) system for all configurations. The primary advantage of the SCAC systsem is reduced aftercooler corrosion since no sea water circulates through the aftercooler. Many other improvements on these engines contribute to minimizing owning and operating costs. A strengthened fuel injection actuation system and rear gear train maintain reliability and durability while providing higher injection pressures. The 3516B also features thermo-laminated heat shields on all marine configurations to maintain surface temperatures below Marine Classification Society regulations.

- Improved fuel economy

- Reduced visible and gaseous emissions

- Enhanced diagnostic and monitoring capabilities

- Increased rated output with no reduction in reliability

Improved fuel economy

Reduced visible and gaseous emissions

Enhanced diagnostic and monitoring capabilities

Increased rated output with no reduction in reliability

Improved fuel economy

Reduced visible and gaseous emissions

Enhanced diagnostic and monitoring capabilities

Increased rated output with no reduction in reliability

Power Rating

- Minimum Rating

- 1726.0bhp

- Maximum Rating

- 2549BHP

- Minimum Rating

- 1726BHP

Engine Specifications

- Aspiration

- TA

- Configuration

- Vee 16 4-Stroke-Cycle Diesel

- Bore

- 6.7in

- Stroke

- 7.5in

- Displacement

- 4210.0in3

- Aspiration

- TA

- Bore

- 6.7in

- Configuration

- Vee 16 4-Stroke-Cycle Diesel

- Displacement

- 4210in³

- Stroke

- 7.5in

Dimensions & Weights

- Length

- 125.2in

- Minimum Width

- 67.1in

- Maximum Width

- 84.4in

- Minimum Height

- 80.8in

- Maximum Height

- 82.7in

- Minimum Dry Weight

- 17537.0lb

- Maximum Dry Weight

- 17700.0lb

- Length

- 125.2in

- Maximum Dry Weight

- 17700lb

- Maximum Height

- 82.7in

- Maximum Width

- 84.4in

- Minimum Dry Weight

- 17537lb

- Minimum Height

- 80.8in

- Minimum Width

- 67.1in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Separate Circuit aftercooler core, corrosion resistant coated (air side)

- Air cleaner, regular duty

- Dual Turbochargers, 152 mm (6 in) OD straight connection

-

- Control System

-

- Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System

- Rigid Wiring Harness

-

- Cooling System

-

- Oil cooler

- Thermostats and housing, full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump

- Auxiliary sea water pump, centrifugal, non-self-priming

-

- Exhaust System

-

- Dry gas tight exhaust manifolds with heat shields

- Dual Turbochargers with watercooled bearings and heat shields

- Exhaust outlet, vertical, 305 mm (12 in) round flanged outlet on engines @ 1800 rpm

-

- Flywheels & Flywheel Housings

-

- Flywheel, SAE No. 00, 183 teeth

- Flywheel housing, SAE No. 00

-

- Fuel System

-

- Fuel filter, RH, with service indicators

- Fuel transfer pump

- Electronically Controlled Unit Injectors

-

- Instrumentation

-

- Graphical Unit (Marine Power Display) for analog or digital display of:

-

- Lube System

-

- Crankcase breather, Top mounted

- Oil filter, RH

- Oil filler and dipstick, RH

- 500 hours sump oil pan

- Oil pump, gear type

-

- Mounting System

-

- Rails, engine mounting, engine length, industrial type, 254 mm (10 in), C-channel

-

- Power Take-offs

-

- Accessory drive

- Lower RH, Lower LH

- Front housing, Two-sided

-

- Protection System

-

- A-III Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection:

-

- General

-

- Vibration damper and guard

- Paint, Caterpillar Yellow engine with black rails.

- Lifting eyes

- NOTE: 1. Engines for heat exchanger cooling do NOT include heat exchanger. 2. When used with competitive generator, a TVA is recommended. An alternative vibration damper may be required. 3. Engine is wired for auto start stop

Optional Equipment:

-

- Charging System

-

- Battery Chargers

- Charging Alternators

-

- Control System

-

- Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

-

- Fuel System

-

- Fuel Cooler

- Fuel priming pumps (LH and RH)

- Flexible fuel lines

- Rigid Fuel Lines

- Primary fuel filter

- LH FUEL FILTER

- Duplex fuel filters

- Fuel level switch

-

- Generators And Generator Attachments

-

- Low voltage connection

- Generator conversion

- Low voltage extension box

- RFI filter

- Bearing temperature detectors (RTD)

- Manual voltage control

- Air filter

- Generator 695 Frame PM 2 BRG

- Generator 693 Frame PM 2 BRG

- Generator 692 Frame PM 2 BRG

- Generator 667 Frame PM 2 BRG

-

- Instrumentation

-

- PL1000T Communication Module

- Customer Interface Box

- Thermocouples

- Remote panel display

- Remote cylinder temperature display

-

- Lube & Fuel System

-

- RH Oil/ RH Fuel, RH Oil/Duplex Fuel, LH Oil/LH Fuel, LH Oil/Duplex Fuel, Duplex Oil/LH Fuel, Duplex Oil/Duplex Fuel

-

- Lube System

-

- Deep Sump Oil Pan

- Oil Pan Drain Valve

- Oil Pan Drain Cover

- Emergency Lube Oil Connections

- Sump pumps

- Oil filters

- Lubricating oil

- Lube system

-

- Mounting System

-

- Rails

-

- Power Take-offs

-

- Flywheel Guard

- Flexible Coupling

- Coupling Hub

- Upper Left Hand Front Location

- Upper Left Hand Rear Location

- Upper Right Hand Front Location

- Upper Right Hand Rear Location

- Lower Left Hand Front Location

- Lower Left Hand Rear Location

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take-offs

- Crankshaft Pulleys

- Damper Guard Removals

-

- Marine Society Requirements

-

- SPRAY SHIELDING .

-

- Protection System

-

- Air inlet shutoffs

- Switches and contactors

- Explosion relief valve

- Oil Temp Sensor

- Intake Manifold Temp Sensor

-

- Special Appearance

-

- Special appearance packages with chrome covers

- Chrome plated relief valves

- Black air cleaners

- Yacht Class Finish

-

- Starting System

-

- Starting motors or barring divice

- Air starting motors options

- Starting aids

- Battery sets - 24 volt - Dry

-

- General

-

- Tool set

- Caterpillar datalink wire

-

- Paints

-

- Special paints

- Special Paint Color Options

-

- Inspections

-

- Inspection charges

-

- Packing

-

- Shrink wrap protection

- Shrink wrap protection - generator

- Storage preservation with glycol solution/vapor corrosion inhibitor

- Storage preservation with vapor corrosion inhibitor

- Export packaging

- AID emblem

-

- Exhaust System

-

- Horizontal Exhaust

- Flexible fittings

- Elbows

- Flanges

- Flange and exhaust expanders

- Mufflers

-

- Air Inlet System

-

- Remote Air Inlet Adapters

-

- Cooling System

-

- Water level switch gauge

- Coolant level sensors

- Connections

- Radiator cooling conversion

- Keel Cooling Conversions

- Heat exchangers

- Auxiliary water pumps

- Sea water pump removal

- Air separator