Cat Water Solutions: 777 (07) Off-Highway Water Truck

Off-Highway Trucks

Mining Trucks (8)

-

798 AC Electric Drive Mining Truck

-

797F Mining Truck

-

793F Mining Truck

-

796 AC Electric Drive Mining Truck

-

794 AC Mining Truck

-

789 Next Generation

-

793 Mining Truck

-

785 Mining Truck (LRC, Tier 4 Final / EU Stage V)

Off-Highway Trucks (8)

-

775G Off-Highway Truck

-

773G Off-Highway Truck

-

770G Off-Highway Truck

-

772G Off-Highway Truck

-

777 (07) Off-Highway Truck

-

770 Off-Highway Truck

-

775 Off-Highway Truck

-

772 (07) Off-Highway Truck

Off-Highway Trucks Bare Chassis (1)

Water Trucks (1)

Overview

Longer description goes here

- ENHANCED SITE SAFETY

- COMFORTABLE CAB

- OPTIMIZED PRODUCTIVITY

- EFFICIENCY & SUSTAINABILITY

- DO MORE WITH LESS FUEL

- SCALABLE CONNECTIVITY

- INTEGRATION & SUPPORT

ENHANCED SITE SAFETY

ENHANCE SAFETY & PRODUCTIVITY

- Lower dust levels, increase visibility, maintain haul road safety — know where and when to water

- With automated water delivery, the operator can remain focused on traffic and driving

- When water tank is full, the auto shutoff feature prevents overfilling and results in increased component life

COMFORTABLE CAB

OPERATOR COMFORT

- Ergonomic, intuitive controls, with left side power window and automatic temperature control

- Spacious cab with window area that supports visibility

- Cab is isolation mounted reducing noise and vibration — sound suppression has decreased noise by 50%

- Lighting packages illuminate both side and front of vehicle

OPTIMIZED PRODUCTIVITY

MEET YOUR PRODUCTION TARGETS

- Properly watered haul roads directly impact fleet cycle times, enabling you to meet production targets.

- Spend less time maintaining haul roads using proper watering techniques to solve overwatering and underwatering

- Prevent damage to trucks and reduce unplanned downtime with properly watered haul roads

EFFICIENCY & SUSTAINABILITY

CONSERVE WATER. USE ONLY WHAT YOU NEED.

- The Cat Water Delivery System (WDS) helps you manage water effectively and sustainability — helping you do more with less.

- WDS utilizes automatic start and stop to help eliminate overwatering at road intersections

- WDS provides variable water flow based on truck speed, ensuring most efficient water placement

DO MORE WITH LESS FUEL

- Auto Neutral Idle: as the 777 idles in a forward gear, the transmission will automatically slip in and out of a neutral state to avoid stalling the torque converter and raising engine rpm.

- Engine Idle Shutdown: when your truck is in park and idles for more than a preset time, the truck will initiate engine shutdown to conserve fuel. This feature can be time adjusted or turned on or off according to your specific needs.

SCALABLE CONNECTIVITY

CONNECT WITH CAT® MINESTAR EDGE™

- Cat MineStar Edge uses cloud-based connectivity through cellular and WiFi connection to collect and manage data at any job site.

- We offer two levels of connectivity (Basic & Premium*) to meet any customer need using Cat MineStar Edge.

- Water Solutions data can help ensure customers are meeting regulatory requirements.

INTEGRATION & SUPPORT

BACKED BY THE ONE YOU TRUST

- Cat Water Solutions trucks are sold, serviced & supported by the local Cat dealer you know and trust.

- Full support of Cat dealer and parts network

- Cat dealer installation & retrofit kits available

- The tank is covered by a Caterpillar Warranty

- The truck is eligible for Equipment Protection Plans (EPP) & Customer Value Agreements (CVAs)

ENHANCED SITE SAFETY

ENHANCE SAFETY & PRODUCTIVITY

- Lower dust levels, increase visibility, maintain haul road safety — know where and when to water

- With automated water delivery, the operator can remain focused on traffic and driving

- When water tank is full, the auto shutoff feature prevents overfilling and results in increased component life

- Monitor tank fill from inside the cab

- The water delivery system features automatic start and stop, based on truck speed, which eliminates overwatering at road intersections to improve safety for all vehicles on site

- Traction Control System (TCS) and Wet Disc Braking is standard on all four corners of the truck

- Automatic Retarding Control (ARC) for downhill grades

COMFORTABLE CAB

OPERATOR COMFORT

- Ergonomic, intuitive controls, with left side power window and automatic temperature control

- Spacious cab with window area that supports visibility

- Cab is isolation mounted reducing noise and vibration — sound suppression has decreased noise by 50%

- Lighting packages illuminate both side and front of vehicle

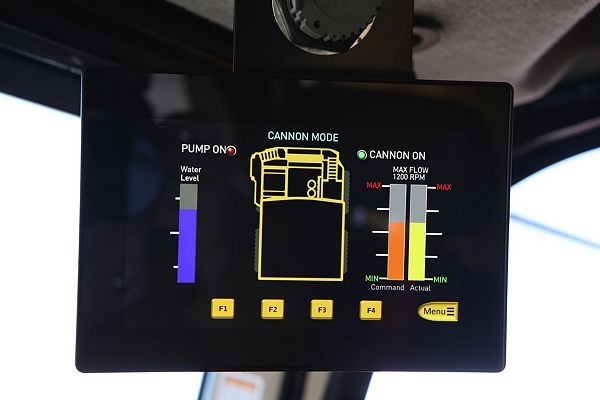

- Factory-installed, integrated and durable ergonomic cab water controls are user-friendly and easy to learn

OPTIMIZED PRODUCTIVITY

MEET YOUR PRODUCTION TARGETS

- Properly watered haul roads directly impact fleet cycle times, enabling you to meet production targets.

- Spend less time maintaining haul roads using proper watering techniques to solve overwatering and underwatering

- Prevent damage to trucks and reduce unplanned downtime with properly watered haul roads

- Pump features soft startup and shuts off automatically when the tank is empty, eliminating damage and preventing the pump from running dry

- The 777 is faster and more efficient with a 7% increase in torque for more power to the ground, new transmission controls, and higher travel speeds.

EFFICIENCY & SUSTAINABILITY

CONSERVE WATER. USE ONLY WHAT YOU NEED.

- The Cat Water Delivery System (WDS) helps you manage water effectively and sustainability — helping you do more with less.

- WDS utilizes automatic start and stop to help eliminate overwatering at road intersections

- WDS provides variable water flow based on truck speed, ensuring most efficient water placement

- The water cannon operates while truck is idling, reducing fuel consumption by up to 50%

DO MORE WITH LESS FUEL

- Auto Neutral Idle: as the 777 idles in a forward gear, the transmission will automatically slip in and out of a neutral state to avoid stalling the torque converter and raising engine rpm.

- Engine Idle Shutdown: when your truck is in park and idles for more than a preset time, the truck will initiate engine shutdown to conserve fuel. This feature can be time adjusted or turned on or off according to your specific needs.

- Speed Limiting: while you can continue to gear limit your trucks, Caterpillar offers speed limiting that allows the truck to travel at a more fuel efficient engine speed and gear selection.

- New APECS transmission controls increase fuel efficiency by maintaining momentum and speed on grade.

WATER DELIVERY SYSTEM:

- The water cannon operates at idle, which reduces fuel consumption during cannon operation by up to 50%.

SCALABLE CONNECTIVITY

CONNECT WITH CAT® MINESTAR EDGE™

- Cat MineStar Edge uses cloud-based connectivity through cellular and WiFi connection to collect and manage data at any job site.

- We offer two levels of connectivity (Basic & Premium*) to meet any customer need using Cat MineStar Edge.

- Water Solutions data can help ensure customers are meeting regulatory requirements.

- Asset Management options include productivity, water usage, fuel & water tank levels, when & where to apply water, geofencing, asset location and remote management of water distribution.

BASIC CONNECTIVITY: EDGE EQUIPMENT TRACKING "I need to know where my truck is and how much water it's distributing."

- Basic Connectivity automates basic data collection, eliminating paper recording by the operator:

- Real-time & historical reporting**

- Truck location and utilization data (starts & stops / routes)

- Fuel and water level

- Whether or not the truck is spraying water

- Water Delivery System utilization (auto vs. manual mode)

PREMIUM CONNECTIVITY: EDGE PRODUCTION RECORDING "I need to know what my operators are doing and how much water I'm using."

- Premium Connectivity offers a comprehensive reporting package with data & reports that can help operators improve watering technique/efficiency

- Water usage by truck/fill station

- Volume of water put down over time and area covered

- Rate of water being put down, water delivery system setting by location, truck, and conditions

- Activity breakdown including time & distance (watering, not watering, stopped, etc.)

- Real-time reporting to the operator on water coverage & need (route, heat map, decay map)**1

- *Basic connectivity package comes standard on all Cat Water Solutions trucks with a 6-month complimentary service-based offering for better data insights. **Based on equipment connectivity via WiFi or cellular data. 1 Feature to be included in future update.

INTEGRATION & SUPPORT

BACKED BY THE ONE YOU TRUST

- Cat Water Solutions trucks are sold, serviced & supported by the local Cat dealer you know and trust.

- Full support of Cat dealer and parts network

- Cat dealer installation & retrofit kits available

- The tank is covered by a Caterpillar Warranty

- The truck is eligible for Equipment Protection Plans (EPP) & Customer Value Agreements (CVAs)

Engine

- Engine Model

- Cat® C32

- Gross Power - SAE J1995

- 1025HP

- Engine Speed

- 1800r/min

- Net Power - SAE J1349

- 916HP

- Engine Power - ISO 14396

- 1008HP

- Emissions

- Fuel Optimized

- Peak Torque - Speed

- 1200r/min

- Net Torque

- 3899ft-lb

- Net Power - ISO 9249

- 916HP

- Net Power - 80/1269/EEC

- 916HP

- Cylinders

- 12

- Bore

- 5.7in

- Stroke

- 6.4in

- Displacement

- 1959in³

- Note (1)

- Net Power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, muffler, and alternator with engine speed at 1,800 rpm.

- Note (2)

- Power rating applies at 1,800 rpm when tested under the specified condition for the specified standard.

- Note (3)

- Ratings based on SAE J1995 standard air conditions of 25° C (77° F) and 100 kPa (29.61 Hg) barometer. Power based on fuel having API gravity of 35 at 16° C (60° F) and an LHV of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F).

- Note (4)

- No engine derating required up to 2286 m (7,500 ft) for Tier 4/Stage V.

- Note (5)

- Meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Engine Model

- Cat® C32B

- Gross Power - SAE J1995

- 1025HP

- Engine Speed

- 1800r/min

- Net Power - SAE J1349

- 916HP

- Engine Power - ISO 14396

- 1008HP

- Emissions

- Fuel Optimized

- Peak Torque - Speed

- 1200r/min

- Net Torque

- 3899ft-lb

- Net Power - ISO 9249

- 916HP

- Net Power - 80/1269/EEC

- 916HP

- Cylinders

- 12

- Bore

- 5.7in

- Stroke

- 6.4in

- Displacement

- 1959in³

- Note (1)

- Net Power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, muffler, and alternator with engine speed at 1,800 rpm.

- Note (2)

- Power rating applies at 1,800 rpm when tested under the specified condition for the specified standard.

- Note (3)

- Ratings based on SAE J1995 standard air conditions of 25° C (77° F) and 100 kPa (29.61 Hg) barometer. Power based on fuel having API gravity of 35 at 16° C (60° F) and an LHV of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F).

- Note (4)

- No engine derating required up to 2286 m (7,500 ft) for Tier 4/Stage V.

- Note (5)

- Available as Tier 4 Final/Stage V equivalent, Tier 3/Stage IIIA equivalent, or Tier 2/Stage II equivalent emission standards.

Weights - Approximate

- Target Gross Machine Weight

- 363000lb

- Chassis Weight

- 115217lb

- Target Gross Machine Weight

- 363000lb

- Chassis Weight

- 115217lb

Operating Specifications

- Note

- Water Tank Capacity Range: 69,700 - 75,700 L (18,400 - 20,000 gal)

- Top Speed - Loaded

- 41.7mile/h

- Note (1)

- Cannon capacity: 2840 L/min (up to 61 m) / 750 gal/min (up to 200 ft)

- Note (2)

- Operator selectable coverage: 0.2-0.8 L/m² (4 kph - 40 kph) / 0.5-0.2 gal/ft² (3 mph - 25 mph)

- Top Speed - Loaded

- 41.7mile/h

- Note

- Water Tank Capacity Range: 69 700 - 75 700 L (18,400 - 20,000 gal)

- Note (1)

- Cannon capacity: 2840 L/min (up to 61 m) / 750 gal/min (up to 200 ft)

- Note (2)

- Operator selectable coverage: 0.2-0.8 L/m² (4 kph - 40 kph) / 0.5-0.2 gal/ft² (3 mph - 25 mph)

Transmission

- Forward - 1

- 6.8mile/h

- Forward - 2

- 9.2mile/h

- Forward - 3

- 12.5mile/h

- Forward - 4

- 16.9mile/h

- Forward - 5

- 22.9mile/h

- Forward - 6

- 30.7mile/h

- Forward - 7

- 41.7mile/h

- Reverse

- 7.7mile/h

- Note

- Maximum travel speeds with standard 27.00R49 (E4) tires.

- Forward - 1

- 6.6mile/h

- Forward - 2

- 9.1mile/h

- Forward - 3

- 11.9mile/h

- Forward - 4

- 16.6mile/h

- Forward - 5

- 22.5mile/h

- Forward - 6

- 30.2mile/h

- Forward - 7

- 40.9mile/h

- Reverse

- 7.5mile/h

- Note

- Maximum travel speeds with standard 27.00R49 (E4) tires.

Final Drives

- Differential Ratio

- 2.736:1

- Planetary Ratio

- 7.0:1

- Total Reduction Ratio

- 19.1576:1

- Differential Ratio

- 2.736:1

- Planetary Ratio

- 7.0:1

- Total Reduction Ratio

- 19.1576:1

Brakes

- Brake Surface Area - Front

- 6331in²

- Brake Surface Area - Rear

- 15828in²

- Brake Standards

- ISO 3450:2011

Body Hoists

- Pump Flow - High Idle

- 6331gal/min

- Relief Valve Setting - Raise

- 2750psi

- Relief Valve Setting - Lower

- 500psi

- Body Raise Time - High Idle

- 15s

- Body Lower Time - Float

- 13s

- Body Lower Time - High Idle

- 13s

- Pump Flow - High Idle

- 6331gal/min

- Relief Valve Setting - Raise

- 2750psi

- Relief Valve Setting - Lower

- 500psi

- Body Raise Time - High Idle

- 15s

- Body Lower Time - Float

- 13s

- Body Lower Time - High Idle

- 13s

Weight Distributions - Approximate

- Front Axle - Empty

- 46%

- Front Axle - Loaded

- 33%

- Rear Axle - Empty

- 54%

- Rear Axle - Loaded

- 67%

- Front Axle - Empty

- 46%

- Front Axle - Loaded

- 33%

- Rear Axle - Empty

- 54%

- Rear Axle - Loaded

- 67%

Suspension

- Empty Loaded Cylinder Stroke Front

- 2.9in

- Empty Loaded Cylinder Stroke Rear

- 2.5in

- Rear axle - Oscillation

- 5.4°

- Empty Loaded Cylinder Stroke Front

- 2.9in

- Empty Loaded Cylinder Stroke Rear

- 2.5in

- Rear axle - Oscillation

- 5.4°

Steering

- Steering Standards

- ISO 5010:2007

- Steer Angle

- 30.5°

- Turning Diameter - Front

- 83ft

- Turning Circle - Clearance Diameter

- 93ft

- Steering Standards

- ISO 5010:2007

- Steer Angle

- 30.5°

- Turning Diameter - Front

- 83ft

- Turning Circle - Clearance Diameter

- 93ft

Tires

- Standard Tire

- 27.00R49 (E4)

- Note (1)

- Productive capabilities of the 777G truck are such that, under certain job conditions, TKPH (TMPH) capabilities of standard or optional tires could be exceeded and, therefore, limit production.

- Note (2)

- Caterpillar recommends the customer evaluate all job conditions and consult the tire manufacturer for proper tire selection.

- Standard Tire

- 27.00R49 (E4)

- Note (1)

- Productive capabilities of the 777 truck are such that, under certain job conditions, TKPH (TMPH) capabilities of standard or optional tires could be exceeded and, therefore, limit production.

- Note (2)

- Caterpillar recommends the customer evaluate all job conditions and consult the tire manufacturer for proper tire selection.

Service Refill Capacities

- Fuel Tank (1)

- 300gal (US)

- Fuel Tank (2)

- 350gal (US)

- Cooling System

- 63.4gal (US)

- Crankcase

- 28.7gal (US)

- Differentials

- 59.9gal (US)

- Final Drive - Each

- 20gal (US)

- Steering System - Including Tank

- 14.1gal (US)

- Brake Hoist System - Includes Tank

- 117gal (US)

- Brake Hoist System

- 85gal (US)

- Torque Converter - Transmission System

- 36.5gal (US)

- Fuel Tank (1)

- 300gal (US)

- Fuel Tank (2)

- 350gal (US)

- Cooling System

- 63.4gal (US)

- Crankcase

- 28.7gal (US)

- Differentials

- 59.9gal (US)

- Final Drive - Each

- 20gal (US)

- Steering System - Including Tank

- 14.1gal (US)

- Brake Hoist System - Includes Tank

- 117gal (US)

- Brake Hoist System

- 85gal (US)

- Torque Converter - Transmission System

- 36.5gal (US)

ROPS

- ROPS Standards

- Rollover Protective Structure (ROPS) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria.

- FOPS Standards

- Falling Objects Protective Structure (FOPS) meets ISO 3449:2005 Level II FOPS criteria.

Sound

- Sound Standards (1)

- The operator Equivalent Sound Pressure Level (Leq) is 73 dB(A) when SAE J1166 FEB2008 is used to measure the value for an enclosed cab. This is a work cycle sound exposure level. The cab was properly installed and maintained. The test was conducted with t

- Sound Standards (2)

- The exterior sound pressure level for the standard machine measured at a distance of 15 m (49 ft) according to the test procedures specified in SAE J88:2008, mid‑gear moving operation is 83 dB(A) for Tier 4 trucks.

- Sound Standards (3)

- Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in a noisy environment.

Cat Water Delivery System (WDS)

- Cannon capacity

- 750gal(US)/min

- Maximum water flow

- 1200gal(US)/min

- Water per spray head (minimum)

- 35gal(US)/min

- Water per spray head (maximum)

- 600gal(US)/min

- Spray head opening range (minimum)

- 0.04in

- Spray head opening range (maximum)

- 0.75in

- Maximum size debris flushed through spray head

- 0.75in

- Spray system hydraulic tank capacity

- 7.25gal (US)

- Maximum number of rear spray heads

- 5

- Minimum number of rear spray heads (recommended 3)

- 2

- Minimum number of front/side spray heads

- 2

- Maximum number of front/side spray heads

- 0

- Maximum water from cannon (idle)

- 600gal(US)/min

- Maximum water from cannon (high idle)

- 1250gal(US)/min

- Maximum cannon spray distance

- 200ft

- Type

- Wet water pump/hydraulic motor coupling

- Note

- Operator selectable coverage: 0.2-0.8 L/m² (4 kph - 40 kph) / 0.5-0.2 gal/ft² (3 mph - 25 mph). Coverage rates above 0.6 L/m² may not be available at higher speeds depending on head count and configuration.

- Note (1)

- Opening is automatically controlled by the system to achieve AutoMode Coverage or Manual Mode Flow Rate.

- Note (2)

- AutoMode Spray controls water coverage automatically to the number of heads being used and ground speed achieved.

- Note (3)

- Manual Mode allows the operator to set a water flow rate that is constant regardless of ground speed.

- Note (4)

- Spray Heads on competitive water distribution systems require tools and maintenance to change flow and spray pattern. Caterpillar is the only company to have variable active spray heads to regulate water spray.

- Note (5)

- Water flow is continually adjusted during operation to conserve water and achieve desired coverage and flow rate

- Cannon capacity

- 750gal(US)/min

- Maximum water flow

- 1200gal(US)/min

- Water per spray head (minimum)

- 35gal(US)/min

- Water per spray head (maximum)

- 600gal(US)/min

- Spray head opening range (minimum)

- 0.04in

- Spray head opening range (maximum)

- 0.75in

- Maximum size debris flushed through spray head

- 0.75in

- Spray system hydraulic tank capacity

- 7.25gal (US)

- Maximum number of rear spray heads

- 5

- Minimum number of rear spray heads (recommended 3)

- 2

- Minimum number of front/side spray heads

- 2

- Maximum number of front/side spray heads

- 0

- Maximum water from cannon (idle)

- 600gal(US)/min

- Maximum water from cannon (high idle)

- 1250gal(US)/min

- Maximum cannon spray distance

- 200ft

- Type

- Wet water pump/hydraulic motor coupling

- Note

- Operator selectable coverage: 0.2-0.8 L/m² (4 kph - 40 kph) / 0.05-0.2 gal/ft² (3 mph - 25 mph). Coverage rates above 0.6 L/m² may not be available at higher speeds depending on head count and configuration.

- Note (1)

- Opening is automatically controlled by the system to achieve AutoMode Coverage or Manual Mode Flow Rate.

- Note (2)

- AutoMode Spray controls water coverage automatically to the number of heads being used and ground speed achieved.

- Note (3)

- Manual Mode allows the operator to set a water flow rate that is constant regardless of ground speed.

- Note (4)

- Spray Heads on competitive water distribution systems require tools and maintenance to change flow and spray pattern. Caterpillar is the only company to have variable active spray heads to regulate water spray.

- Note (5)

- Water flow is continually adjusted during operation to conserve water and achieve desired coverage and flow rate

Braking System

- Brake Surface - Front

- 6331in²

- Brake Surface - Rear

- 15828in²

- Brake Standards

- ISO 3450:2011

- Brake Surface - Front

- 6331in²

- Brake Surface - Rear

- 15828in²

- Brake Standards

- ISO 3450:2011

Cab

- Air Conditioning

- 18390Btu/lb

- Heater / Defroster

- 43930Btu

- ROPS Standards (1)

- Rollover Protective Structure (ROPS) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria.

- FOPS Standards

- Falling Objects Protective Structure (FOPS) meets ISO 3449:2005 Level II FOPS criteria.

- Note (1)

- The operator Equivalent Sound Pressure Level (Leq) is 73 dB(A) when SAE J1166 FEB2008 is used to measure the value for an enclosed cab. This is a work cycle sound exposure level. The cab was properly installed and maintained. The test was conducted with t

- Note (2)

- The exterior sound pressure level for the standard machine measured at a distance of 15 m (49 ft) according to the test procedures specified in SAE J88:2008, mid-gear moving operation is 83 dB(A).

- Note (3)

- Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in a noisy environment.

- Air Conditioning

- 18390Btu/lb

- Heater / Defroster

- 43930Btu

- ROPS Standards (1)

- Rollover Protective Structure (ROPS) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria.

- FOPS Standards

- Falling Objects Protective Structure (FOPS) meets ISO 3449:2005 Level II FOPS criteria.

- Note (1)

- The operator Equivalent Sound Pressure Level (Leq) is 73 dB(A) when SAE J1166 FEB2008 is used to measure the value for an enclosed cab. This is a work cycle sound exposure level. The cab was properly installed and maintained. The test was conducted with t

- Note (2)

- The exterior sound pressure level for the standard machine measured at a distance of 15 m (49 ft) according to the test procedures specified in SAE J88:2008, mid-gear moving operation is 83 dB(A).

- Note (3)

- Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in a noisy environment.

Tank Configurations

- Water Tank Capacity

- up to 75,700 L (20,000 gal)

- Note

- Multiple tank configurations are offered based on customer preference and regional locations. Water Tank Capacity Range: 69,700 - 75,700 L (18,400 - 20,000 gal)

- Machine Weight (with water tank full)

- 307,946 - 327,964 lb / 139,682 - 148,762 kg

- Empty Machine Operating Weight (without water / with fuel)

- 155,993 - 161,416 lb / 70,757 - 73,217 kg

- Water Tank - Max Empty Weight (no WDS)

- 38,669 - 44,092 lb / 17,540 - 20,000 kg

- Note (1)

- Cat branded tanks include additional features and options commonly selected by customers in the industry. Splash guards, fill chute, and rock ejectors are standard.

- Note (2)

- Hoist cylinder mounting on all tank offerings enhances serviceability.

- Water Tank Capacity

- up to 75 700 L (20,000 gal)

- Note

- Multiple tank configurations are offered based on customer preference and regional locations. Water Tank Capacity Range: 75 400 - 75 700 L (19,900 - 20,000 gal)

- Machine Weight (with water tank full)

- 327,964 - 327,964 lb / 147 172 - 148 762 kg

- Empty Machine Operating Weight (without water / with fuel)

- 160,307 - 162,323 lb / 72 714 - 73 629 kg

- Water Tank - Max Empty Weight (no WDS)

- 42,983 - 44,092 lb / 19 497 - 20 000 kg

- Note (1)

- Cat branded tanks include additional features and options commonly selected by customers in the industry. Splash guards, fill chute, and rock ejectors are standard.

- Note (2)

- Hoist cylinder mounting on all tank offerings enhances serviceability.

Standard/Optional Features

Standard Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Powertrain

-

- Autostall

- Engine idle shutdown

- Air-To-Air Aftercooler (ATAAC)

- Air cleaner with precleaner (2)

- Automatic cold mode idle control

- Electric priming pump

- Electric cold weather start (two starters and four batteries)

- Ether starting aid

- Exhaust, muffler

- Fuel filter/water separator

- Turbocharger (2)

- Braking system:

– Extended Life Brakes

– Brake wear indicator

– Automatic Retarder Control (ARC) (utilizes oil-cooled, multiple disc brakes)

– Brake release motor (towing)

– Manual retarder (utilizes oil-cooled, multiple disc brakes)

– Oil-cooled, multiple disc (front/rear)

– Parking

– Secondary

– Service - Transmission

– Auto neutral idle

– APECS Software

– ECPC - Part Throttle Shifting

– 7-speed automatic powershift with Torque Shift Management Electronic Clutch Pressure Control

– Body up-shift inhibitor

– Directional shift management

– Downshift inhibitor

– Neutral start switch

– Neutral coast inhibitor

– Reverse shift inhibitor

– Reverse neutralizer during dumping

– Programmable top gear selection

-

- Suspension Systems

-

- Suspension, rear

-

- Electrical

-

- Alarm, backup

- Alternator, 115 ampere

- Auxiliary jump start receptacle

- Batteries, maintenance-free, 12V (4), 190 amp-hour

- Electrical system, 25 AMP, 24V to 12V converter

- Lighting system

– Backup light (halogen)

– Directional signals/hazard warning, (front and rear LED)

– Headlights, (halogen) with dimmer

– Payload, indicator lights

– Operator access courtesy lights

– Side profile lights

– Stop/tail lights (LED)

– Service lights

-

- Operator Environment

-

- Air conditioning

- Ashtray and cigarette lighter

- Coat hook

- Cup holders (4)

- Diagnostic connection port, 24V

- Entertainment Radio Ready

– 5 amp converter

– Speakers

– Antenna

– Wiring harness - Gauges/indicators

– Brake oil temperature gauge

– Coolant temperature gauge

– Hour meter

– Tachometer

– Engine overspeed indicator

– Fuel level

– Speedometer with odometer

– Transmission gear indicator - Heater/defroster (11 070 kCal/43,930 BTU)

- Auto temp control

- Fluid level monitoring

- Hoist lever

- Horn, electric

- Light – dome

- Light – courtesy

- Load counter, automatic

- Advisor display

- VIMS

- TPMS

- Foot rest

- Mirrors – heated

- Power port, 24V and 12V (2)

- ROPS cab, insulated/sound suppressed

- Cat Comfort Series III

– Full air suspension

– Retractable 3-point seat belt with shoulder harness - Steering wheel, padded, tilt and telescopic

- Storage compartment

- Sun visor

- Throttle lock

- Window, right side, hinged access/egress

- Electric left side window control

- Windshield wiper (intermittent) and washer

- Tinted, laminated glass

-

- Cat Technology Products

-

- Adaptive economy mode

- Object detection (4 cameras, 4 radars)

- Product Link™ Ready (Level 1)

- TKPH/TMPH (Tons Kilometer Per Hour/ Tons Mile Per Hour)

- Work Area Vision System (WAVS)

- Cat MineStar Edge™: Level 1 - Basic (Equipment Tracking)*

- *Basic connectivity package comes standard on all Cat Water Solutions trucks with a 6-month complimentary service-based offering

-

- Guards

-

- Engine crankcase

- Driveline

- Fan and A/C

-

- Fluids

-

- Extended Life Coolant to –35° C (–30° F)

-

- Other Standard Equipment

-

- Body mounting group

- Body safety pin (secures body in up position)

- Body down indicator

- CD-ROM parts book

- Center-mounted rims

- Fuel tank (1136 L/300 gal)

- Ground level battery disconnect

- Ground level engine shutdown

- Ground level grease fittings

- Reservoirs (separate)

– Brake/hoist

– Steering

– Transmission/torque converter - Rims 19.5 × 49

- Rock ejectors

- Supplemental steering (automatic)

- Tie down eyes

- Tow hooks (front)/Tow pin (rear)

- Vandalism protection locks

- Wiggins fast fuel

- Traction Control System (TCS) (new version)

- Attachment Zone

-

- Cat Water Delivery System (wds)

-

- Controls: Factory installed and integrated into cab

- Water System Monitor: integrated into cab, programmable spray configurations, automatic diagnostic messages

- Variable Hydraulic Pump Drive: 1,200 gpm at speeds of 3 to 25 mph with auto shut-off and soft startup

- Stainless Steel Spray Heads: maintenance free, patented design resists corrosion

- Independent Hydraulic Cooling System: minimizes overheating

- Water Cannon: hydraulically controlled, integrated joystick with cab controls, optional nozzles

- Parts & service available through global Cat dealer network

-

- Cat Branded Water Tank Offerings With Options

-

- Cat branded tanks include additional features and options commonly selected by customers in the industry.

– Splash guards, fill chute, and rock ejectors are standard.

– Hoist cylinder mounting on all tank offerings enhances serviceability

– Manufactured and supplied by recognized tank providers (covered by a Caterpillar warranty)

- Cat branded tanks include additional features and options commonly selected by customers in the industry.

Optional Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Optional Equipment

-

- Cab precleaner

- Cat Engine Brake

- Clustered grease fittings

- Cold weather packages

- Fluid fill service center

- HID lights

- Mirrors, convex

- Mirrors, heated

- Spare rim

- Visibility package (meets ISO 5006 requirements)

- Wheel chocks

- Work Area Vision System (WAVS)

-

- Cat Technology Products

-

- Cat MineStar Edge™: Level 2 - Premium (Production Recording)**

- **Phased introduction 2022

777 Off-Highway Truck bare chassis

777 Off-Highway Truck bare chassis