Cat?� C1.1 Diesel Engine

-

Cat® C9 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

Cat® C2.2 Diesel Engine

-

Cat?� 3512 Fire Pump

-

Cat?� 3406C Fire Pump Engine

-

Cat?� 3508 Fire Pump

-

Cat?� 3516 Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat?� C18 Industrial Power Unit

-

Cat?� C18 Diesel Fire Pump

-

Cat?� C15 Industrial Power Unit

-

Cat?� C13 Industrial Power Unit

-

Cat?� C11 Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit

-

Cat?� C32 Industrial Power Unit

-

Cat?� C18 Industrial Power Unit (<560 kW)

-

Cat?� C15 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit HRC

-

Cat?� C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� 3616 Industrial Diesel Engine

-

Cat?� 3612 Industrial Diesel Engine

-

Cat?� 3608 Industrial Diesel Engine

-

Cat?� 3606 Industrial Diesel Engine

-

Cat?� 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat?� 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat?� 3512B Industrial Diesel Engine

-

Cat?� 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat?� 3508 Diesel Engine

-

Cat?� C32

-

Cat?� C27 Industrial Diesel Engine

-

Cat?� C18 Industrial Diesel Engine

-

Cat?� C15 Industrial Diesel Engine

-

Cat?� 3406C Diesel Engine

-

Cat?� C13 Industrial Diesel Engine

-

Cat?� C11 Industrial Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7 Industrial Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?�3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat?� C3.6 Industrial Diesel Engine

-

Cat?� C2.8 Industrial Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C0.7 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat?� 3516E Diesel Engine

-

Cat?� C32 Diesel Engine

-

Cat?� C27 Diesel Engine

-

Cat?� C9.3B Diesel Engine

-

Cat® C3.6 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C2.8 Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

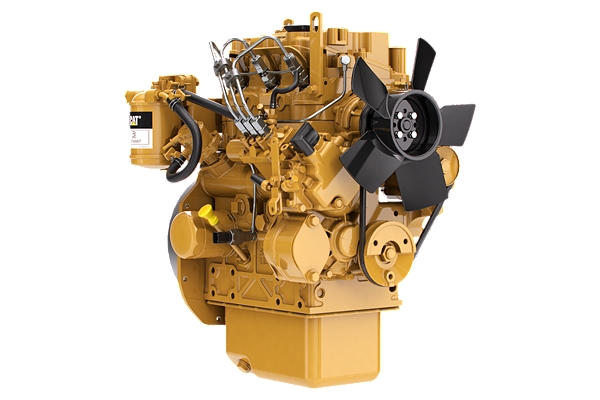

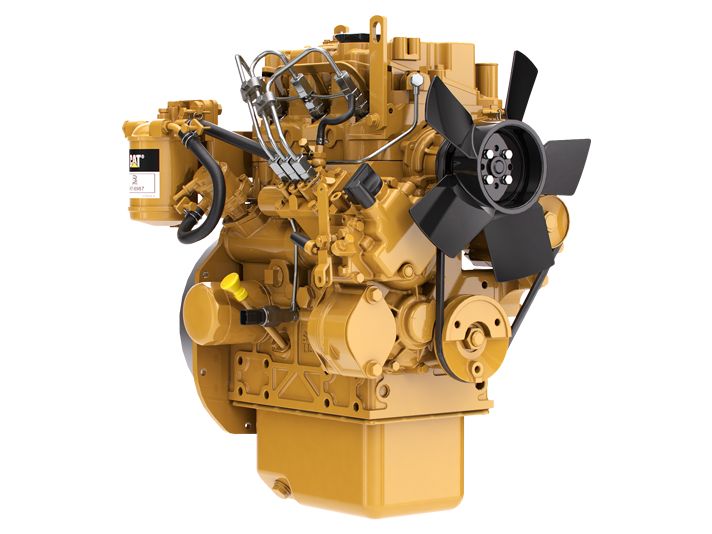

Cat?� C1.1 Diesel Engine

Overview

The Cat?� C1.1 Industrial Diesel Engine is offered in ratings ranging from 14.4-18.4 bkW (19.3-24.7 bhp) @ 1800-2800 rpm. These ratings meet U.S. EPA Tier 4 Final emission standards. Ratings: 13.7-21.0 bkW (18.4-28.2 bhp) @ 2200-3000 rpm are also available for Europe and, depending on applicable emission standards, may be introduced in other regulated areas. Nonroad engines less than 19 kW (25 hp) are not currently subject to EU emission standards. Industries and applications powered by C1.1 engines include: Aircraft Ground Support, Auxiliary Power Units, Bore/Drill Rigs, Chippers/Grinders, Compactors/Rollers, Construction, Forestry, General Industrial, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Light Towers, Pumps, Trenchers, Underground Mining Equipment.

package is crucial. And for jobs that require that extra bit of powe...

fatigued and noise levels in regulated areas aren't exceeded.

package is crucial. And for jobs that require that extra bit of power, there's a turbocharged option that delivers in almost any condition, at any altitude.

fatigued and noise levels in regulated areas aren't exceeded.

General

- Engine Configuration

- In-Line 3, 4-Stroke-Cycle Diesel

- Cooling System Capacity

- 1.9 L (2 qt)

- Lube System (refill)

- 3.4-4.4 L (3.6-4.6 qt)

- Bore

- 3in

- Stroke

- 3.2in

- Displacement

- 69in³

- Aspiration

- Naturally Aspirated (NA)/Turbocharged (T)

- Compression Ratio

- 23.0:1

- Combustion System

- Indirect Injection

- Rotation from Flywheel End

- Counterclockwise

- Engine Configuration

- In-Line 3

- Bore

- 77 mm (3.03 in)

- Stroke

- 81 mm (3.19 in)

- Displacement

- 1.13 L (69 in³)

- Cooling System - Capacity

- 1.9 L (2 qt)

- Lube System - Refill

- 3.4-4.4 L (3.6-4.6 qt)

- Aftertreatment

- -

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 491 mm (19.33 in)

- Width

- 400 mm (15.74 in)

- Height

- 576 mm (22.7 in)

- Weight - Net Dry (Basic Operating Engine Without Optional Attachments)

- 87 kg (191 lb)

Power Rating

- Minimum Power

- 19.3HP

- Maximum Power

- 24HP

- Rated Speed

- 2800 rpm

- Maximum Torque

- 63lb-ft @ 1600 rpm

Emission Standards

- Emissions

- U.S. EPA Tier 4 Final, EU Stage V

Engine Dimensions - Approximate

- Height

- 576 mm (22.7 in)

- Length

- 491 mm (19.33 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 87 kg (191 lb)

- Width

- 400 mm (15.74 in)

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 211lb

- Width

- 15.8in

- Length

- 19.3in

- Height

- 22.7in

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Inlet manifold with choice of inlets.

-

- Control System

-

- Alternator 12 volt 65 amp

- Starter motor 12 volt

- Glow plug starting aid

-

- Cooling System

-

- Belt-driven coolant pump

- Coolant temperature switch

-

- Flywheel And Flywheel Housing

-

- SAE No. 6 1/2 flywheel

- Choice of SAE No. 5 or standard backplate flywheel housing

- U.S. EPA Tier 4 Final: Standard backplate flywheel housing and flatface flywheel

-

- Fuel System

-

- Fuel injection pump

- Spin-on fuel filter

-

- Lube System

-

- Low profile oil pan

- Spin-on lube oil filter

- Lube oil pressure switch

-

- Power Take Off (pto)

-

- Provision for Power Take Off (PTO)

-

- General

-

- Cast iron, engine block

- Cast iron exhaust manifold--side outlet

- Cold start capability to -20° C (-4° F)

- Paint: Caterpillar yellow, with optional colors available at request

Optional Equipment: