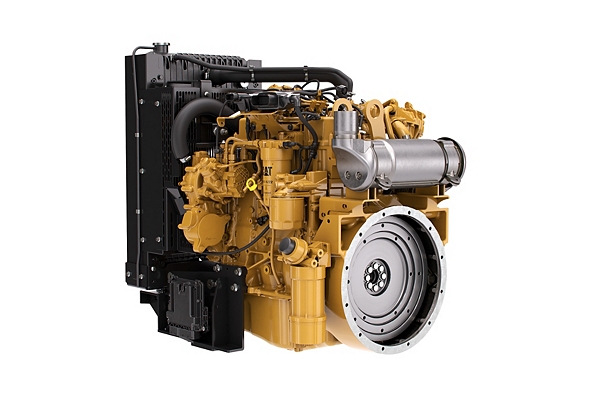

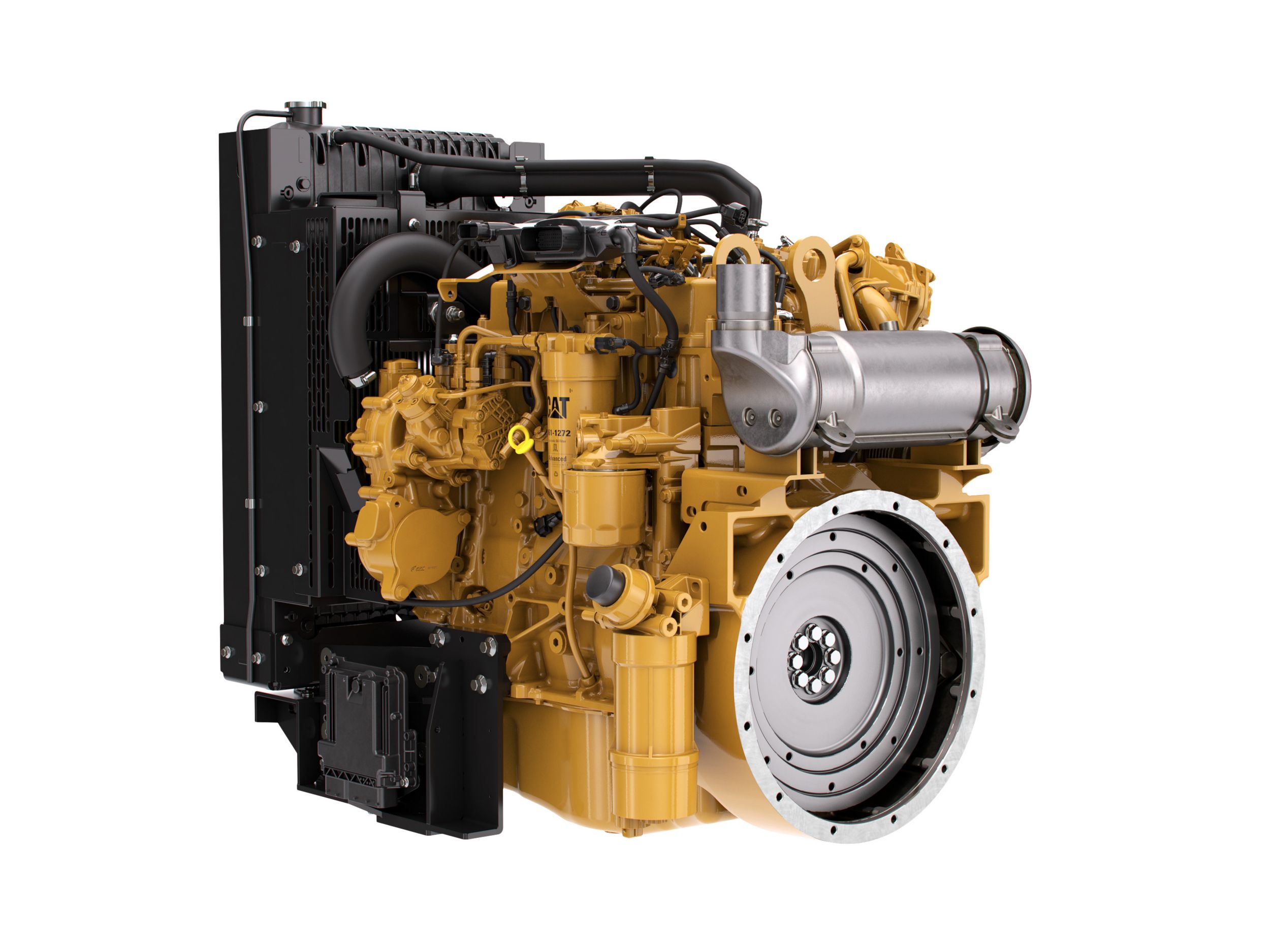

Cat® C3.4B Industrial Power Unit

Industrial

Industrial (70)

-

Cat® C9 Industrial Power Unit

-

Cat® C3.4B Industrial Power Unit

-

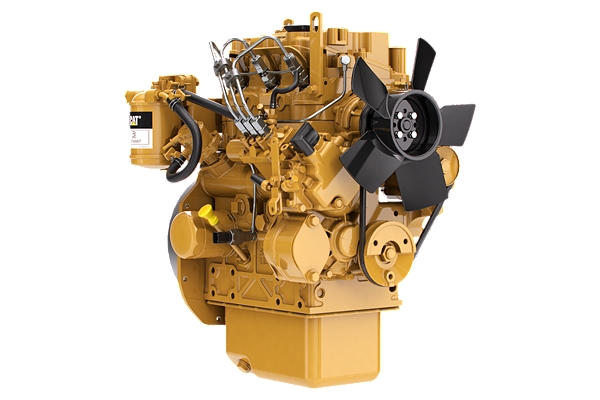

Cat® C2.2 Diesel Engine

-

Cat?� 3512 Fire Pump

-

Cat?� 3406C Fire Pump Engine

-

Cat?� 3508 Fire Pump

-

Cat?� 3516 Fire Pump

-

Cat® 3516C Industrial Power Unit

-

Cat?� C18 Industrial Power Unit

-

Cat?� C18 Diesel Fire Pump

-

Cat?� C15 Industrial Power Unit

-

Cat?� C13 Industrial Power Unit

-

Cat?� C11 Industrial Power Unit

-

Cat® C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit

-

Cat?� C32 Industrial Power Unit

-

Cat?� C18 Industrial Power Unit (<560 kW)

-

Cat?� C15 Industrial Power Unit

-

Cat?� C9.3B Industrial Power Unit HRC

-

Cat?� C7.1 Industrial Power Unit

-

Cat?� C4.4 Industrial Power Unit

-

Cat?� 3616 Industrial Diesel Engine

-

Cat?� 3612 Industrial Diesel Engine

-

Cat?� 3608 Industrial Diesel Engine

-

Cat?� 3606 Industrial Diesel Engine

-

Cat?� 3516C Industrial Diesel Engine

-

Cat® 3516B Industrial Diesel Engine

-

Cat?� 3516 Industrial Diesel Engine

-

Cat® 3512C Industrial Diesel Engine

-

Cat?� 3512B Industrial Diesel Engine

-

Cat?� 3512 Industrial Diesel Engine

-

Cat® 3508B Industrial Diesel Engine

-

Cat?� 3508 Diesel Engine

-

Cat?� C32

-

Cat?� C27 Industrial Diesel Engine

-

Cat?� C18 Industrial Diesel Engine

-

Cat?� C15 Industrial Diesel Engine

-

Cat?� 3406C Diesel Engine

-

Cat?� C13 Industrial Diesel Engine

-

Cat?� C11 Industrial Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7.1 Diesel Engine

-

Cat?� C7 Industrial Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?�3054C Industrial Diesel Engine

-

Cat® C3.6 Industrial Diesel Engine for Tractors

-

Cat?� C3.6 Industrial Diesel Engine

-

Cat?� C2.8 Industrial Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C1.1 Diesel Engine

-

Cat?� C0.7 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat?� 3516E Diesel Engine

-

Cat?� C32 Diesel Engine

-

Cat?� C27 Diesel Engine

-

Cat?� C9.3B Diesel Engine

-

Cat® C3.6 Diesel Engine

-

Cat?� C4.4 Diesel Engine

-

Cat?� C7.1 ACERT?�� Diesel Engine

-

Cat® C3.6 Diesel Engine for Tractors

-

Cat® C2.8 Diesel Engine

-

Cat?� C2.2 Diesel Engine

-

Cat?� C1.5 Diesel Engine

-

Cat?� C0.5 Diesel Engine

-

Cat® C0.7 Diesel Engine

-

Cat?� C1.1 Diesel Engine

Overview

The Cat® C3.4B Industrial Power Unit is offered at 75-86 bkW (100-115 bhp), which meets U.S. EPA Tier 4 Final, EU Stage IV emission standards. Conveniently pre-configured for a wide range of applications, the Cat Industrial Power Unit is a complete power package containing a radiator, flywheel, alternator and alternator wiring completely pre-assembled for fast, straightforward installation in a number of OEM, customer and packager applications. These fuel efficient units are ready made for irrigation, industrial, mining and other pump applications.

- Reliable, Quiet and Durable Power

- High Performance

- Fuel Efficiency

- Fuel & Oil

- Broad Application Range

- World-class Product Support Offered Through Global Cat Dealer Network

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Leading-edge technology provides significant improvements in power, torque, fuel consumption and response. Technology includes single smart wastegated turbo systems, durable high pressure common rail technology, and closed circuit breathing system.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Fuel & Oil

Tier 4 Interim or Tier 4 Final, Stage IIIB or Stage IV engines require Ultra Low Sulfur Diesel (ULSD) fuel containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Cat engines are designed to accommodate B20 biofuel. Your Cat dealer can provide more informatio...

Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOS℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Leading-edge technology provides significant improvements in power, torque, fuel consumption and response. Technology includes single smart wastegated turbo systems, durable high pressure common rail technology, and closed circuit breathing system.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Fuel & Oil

Tier 4 Interim or Tier 4 Final, Stage IIIB or Stage IV engines require Ultra Low Sulfur Diesel (ULSD) fuel containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Cat engines are designed to accommodate B20 biofuel. Your Cat dealer can provide more information regarding fuel and oil.

Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOS℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Power Rating

- Minimum Power

- 100bhp

- Maximum Power

- 115bhp

- Rated Speed

- 2200

- Minimum Power

- 100HP

- Maximum Power

- 115HP

- Rated Speed

- 2200

- Maximum Torque

- 310lb-ft @ 1400 rpm

Emission Standards

- Emissions

- U.S. EPA Tier 4 Final, EU Stage IV nonroad emission standards. U.S. EPA Tier 4 Interim Equivalent or EU Stage IIIB Equivalent ratings also available using EPA or EU Flex Provisions.

- Emissions

- U.S. EPA Tier 4 Final

General

- Engine Configuration

- In-Line 4, 4-Stroke-Cycle Diesel

- Bore

- 99 mm (3.9 in)

- Stroke

- 110 mm (4.3 in)

- Displacement

- 3.4 L (207.5 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Compression Ratio

- 17:1

- Rotation (from flywheel end)

- Counterclockwise

- Engine Configuration

- In-Line 4, 4-Stroke-Cycle Diesel

- Bore

- 99 mm (3.9 in)

- Stroke

- 110 mm (4.3 in)

- Displacement

- 3.4 L (207.5 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Compression Ratio

- 17.0:1

- Rotation from Flywheel End

- Counterclockwise

- Bore

- 3.9in

- Stroke

- 4.3in

- Displacement

- 207.5in³

- Aftertreatment

- DOC+SCR

Power Unit Dimensions - Approximate

- Length

- 1252 mm (49.3 in)

- Width

- 705 mm (27.7 in)

- Height

- 1033 mm (40.7 in)

- Weight - Approximate, Net Dry - Standard Configuration Without Oil, Cooling, Clutch, Compressor, A/C

- 407 kg (897 lb)

Aftertreatment Dimensions - Approximate

- DOC Length

- 320 mm (12.6 in)

- DOC Weight

- 15 kg (33 lb)

- DOC Diameter

- 196 mm (7.7 in)

- SRC Length

- 520 mm (20.47 in)

- SCR Weight

- 20 kg (44 lb)

- SCR Diameter

- 251 mm (9.88 in)

Power Unit Dimensions

- Length

- 40.7in

- Width

- 27.7in

- Height

- 49.3in

- Weight

- 897lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Standard air cleaners

-

- Control System

-

- Full electronic control system

- Fully integrated, engine-mounted electronic control unit

- Waterproof connectors and wiring looms

- Flexible and configurable software features and J1939 standard communications I/O

-

- Flywheels And Flywheel Housing

-

- SAE3 configuration

-

- Fuel System

-

- Engine-mounted fuel filters

- Electronic high pressure common rail fuel pump and injectors

-

- Lube System

-

- Lubricating oil filters and breathers

-

- General

-

- Cold start capability to -20° C (-4° F)

- Paint: Caterpillar yellow, with optional colors available at request

-

- U.s. Epa Tier 4 Final, Eu Stage Iv Aftertreatment/clean Emissions Control Equipment

-

- Diesel Oxidation Catalyst (DOC)

- Selective Catalytic Reduction (SCR)

- SCR Auxiliaries are available in a range of tanks and heated lines

Optional Equipment: